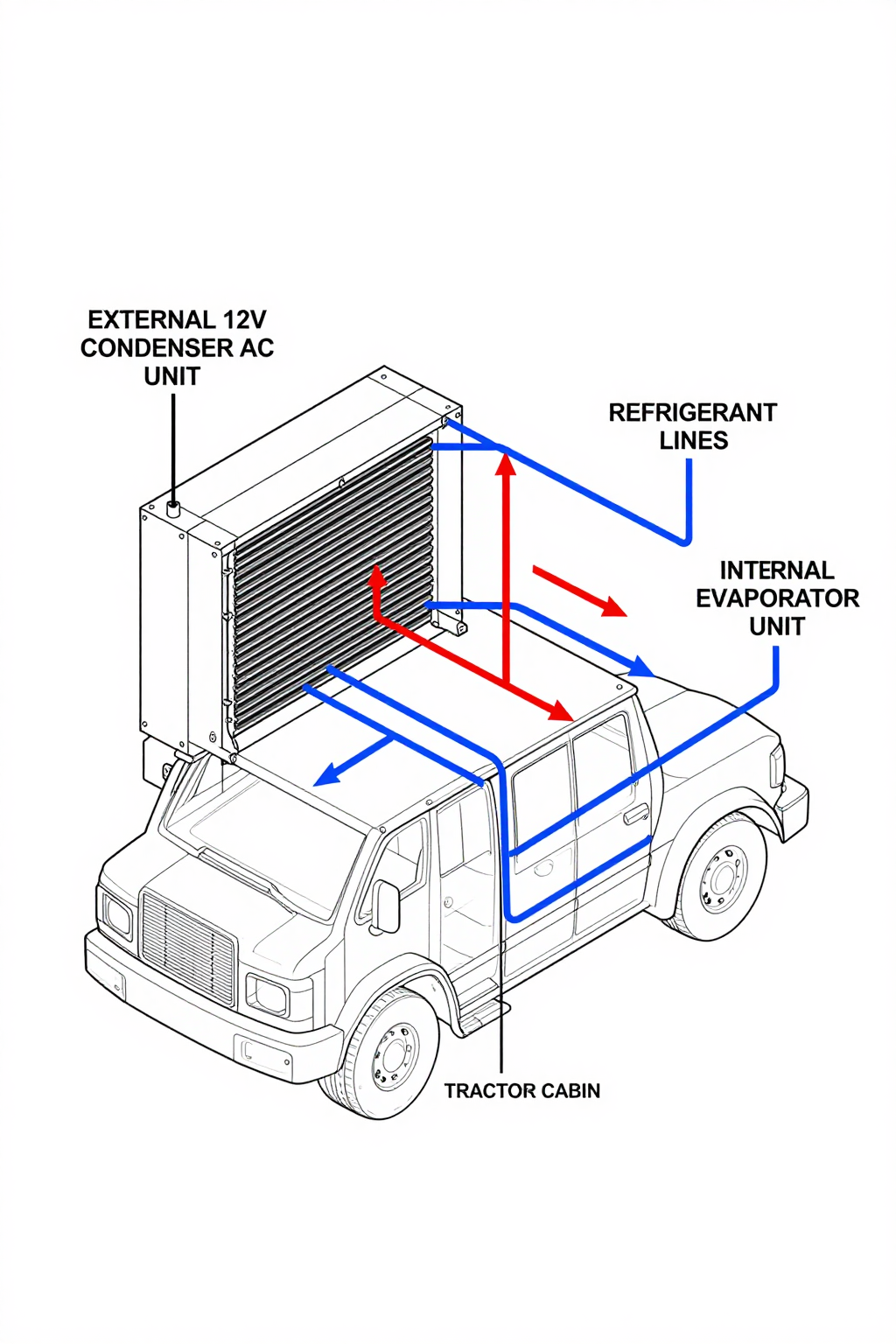

The “Morning After” Noise Problem

A common challenge in mobile cooling integration involves noise profile changes after deployment. A system that performs to spec on a static test bench may exhibit increased noise, panel rattling, or reduced performance after extended operation on rough terrain. Upon inspection, technicians often identify stress fractures in refrigerant lines or loosened fasteners.

These symptoms typically point to the vibration mounting strategy rather than a defect in the portable DC air conditioner itself. In a mobile environment (truck, van, or heavy machinery), the chassis can transmit significant kinetic energy. Without adequate decoupling, the cooling unit may be subjected to forces outside its design envelope.

Physics of Failure: Hard Mounting Dynamics

DC compressors generate specific frequency vibrations based on their operating RPM. While RIGID’s rotary compressors are balanced, they produce kinetic energy inherent to any rotating machinery. When this energy encounters a rigid chassis, two mechanical phenomena may occur:

1. Work Hardening of Copper

Copper is ductile but susceptible to work hardening under cyclic stress. If copper refrigerant lines are rigidly mounted to a vibrating chassis without stress relief, the metal undergoes cyclic deformation. Over time, this can alter the crystalline structure, reducing ductility. This process increases the risk of fractures at stress concentration points, such as braze joints, potentially leading to refrigerant loss.

2. Resonance Amplification

Every physical assembly has a natural frequency. If the compressor’s forcing frequency (e.g., 50Hz at 3000 RPM) aligns with the natural frequency of a mounting plate or vehicle panel, resonance may occur. This phenomenon can amplify the vibration amplitude, potentially increasing the perceived noise level significantly and accelerating mechanical fatigue in connected components.

The Solution: 3-Axis Isolation Strategy

To protect the Micro DC Aircon core assembly, engineers typically implement a multi-layered suspension strategy. The goal is to tune the natural frequency of the mounting system away from the operating frequency of the compressor.

| Component | Mounting Strategy | Engineering Goal |

|---|---|---|

| Compressor Base | Rubber Grommets (Shore 40-50A) | Absorb primary motor frequency (High Hz) |

| Refrigerant Lines | Flexible loops (Vibration Eliminators) | Reduce stress transfer to rigid joints |

| Unit Chassis | Wire Rope Isolators (Optional) | Decouple road shock (Low Hz / High G) |

Material Science: Selecting the Right Isolator

Isolator material selection impacts longevity in different environments.

- Natural Rubber: Offers excellent damping characteristics but may degrade if exposed to oils or intense UV light. Often suited for internal, shielded mounts.

- Neoprene: Provides better oil resistance but may stiffen in sub-zero temperatures, potentially transmitting more vibration in cold climates.

- Silicone: Operates across a wide temperature range (-50°C to 200°C) but generally has lower tear strength. Often selected for extreme thermal environments.

- Wire Rope Isolators: Constructed from stainless steel cable. They provide damping in all three axes and are resistant to oil, chemicals, and temperature extremes. Frequently used in heavy mining or military equipment.

Field Installation Checklist

1. Compression Control

Over-tightening mounting nuts can compromise isolation. If a rubber grommet is compressed until it bulges significantly, its spring rate increases, effectively creating a rigid mount. Utilizing nyloc nuts tightened to specification, or shouldered bolts that limit compression, helps maintain the intended isolation characteristics.

2. Service Loops for Hoses

Refrigerant hoses should not be installed under tension. Including a “service loop” (a U-shape or 360-degree loop) allows the hose to flex as the compressor moves independently of the frame. This loop acts as a mechanical buffer.

3. Mass Loading

Mounting the unit on a rigid base plate (steel vs aluminum) increases mass inertia. A heavier base resists vibration excitation more effectively than a thin sheet metal panel. In retrofits involving thin sheet metal, adding a stiffening rib or a heavy rubber mat is a common mitigation technique.

Conclusion: Engineering for Reliability

System reliability is often a function of integration detail. By respecting the physics of portable DC air conditioner vibration mounting, integrators can reduce the risk of mechanical fatigue in mobile applications. A proper suspension strategy protects both the cooling asset and the vehicle infrastructure.

For a complete list of available cooling modules and mounting accessories, please visit our Store Categories.

Frequently Asked Questions

Q: Can I mount the unit on its side to save space?

A: Generally, no. Rotary compressors rely on an internal oil sump for lubrication. Mounting angles exceeding 30° from vertical may interrupt oil pickup, leading to lubrication failure.

Q: My unit is rattling. What do I check first?

A: Initial checks should include inspecting for loose external fasteners and ensuring no copper lines are making metal-on-metal contact with the chassis. Aging rubber grommets should also be inspected for hardening or cracking.

0 条评论