Field Snapshot: Cleaning Durability Cooling Device Connectors

In environments requiring frequent on-site cleaning and disinfection—such as food processing lines, medical facilities, or cleanrooms—system integrators often encounter a specific, recurring failure mode. The active cooling units perform thermally, but the system fails due to ingress or signal loss at the interface. This scenario typically involves aggressive chemical washdowns where the cleaning durability cooling device connectors provide becomes the critical limiting factor. The stakes are high: connector failure leads to fluid ingress, short circuits, and unscheduled downtime.

The challenge rarely stems from the initial seal quality. Instead, it arises from the cumulative interaction between harsh cleaning agents, mechanical scrubbing, and the material composition of the connector housing and gaskets. This field note explores how to troubleshoot and select interconnects that withstand repeated sanitation cycles without degrading.

Initial Checks: Material and Mechanical Integrity

When troubleshooting premature connector failure in sanitary deployments, engineers should prioritize the following checks before assuming a manufacturing defect:

- Chemical Compatibility Audit: Verify the specific cleaning agents used (e.g., bleach, ammonia, alcohol, hydrogen peroxide) against the chemical resistance charts for the connector’s gasket and housing materials. A mismatch here is the most common cause of failure.

- Mechanical Stress Points: Inspect for tension on the cables during the cleaning process. Scrubbing or high-pressure spraying can exert lateral forces that momentarily deform the seal, allowing micro-ingress.

- Mating Cycle History: Determine if the connectors are frequently unmated for cleaning. High-cycle wear on the contacts and seal surfaces can degrade the ingress protection rating over time.

Failure Modes & Constraints

Understanding how these components fail in the field helps in selecting robust alternatives. The following symptoms often point to specific underlying constraints:

- Swollen or Softened Gaskets: Likely caused by chemical absorption. This deformation prevents the seal from seating correctly, compromising the enclosure.

- Stress Corrosion Cracking: Often observed in polycarbonate or standard plastic housings when exposed to certain solvents or surfactants. This structural failure bypasses the seal entirely.

- Contact Corrosion: Indicates that moisture or vapors have penetrated the seal. This frequently occurs if the connector lacks a secondary locking mechanism or if the backshell is not properly potted.

- Cable Jacket Embrittlement: While not the connector itself, a hardening cable jacket transfers excessive torque to the connector body, breaking the seal during movement.

- Intermittent Signal: Suggests fretting corrosion or loss of normal force on contacts, potentially due to thermal cycling combined with chemical ingress.

Decision Gates for Connector Selection

Selecting the right interface requires navigating several decision gates based on the specific environmental constraints.

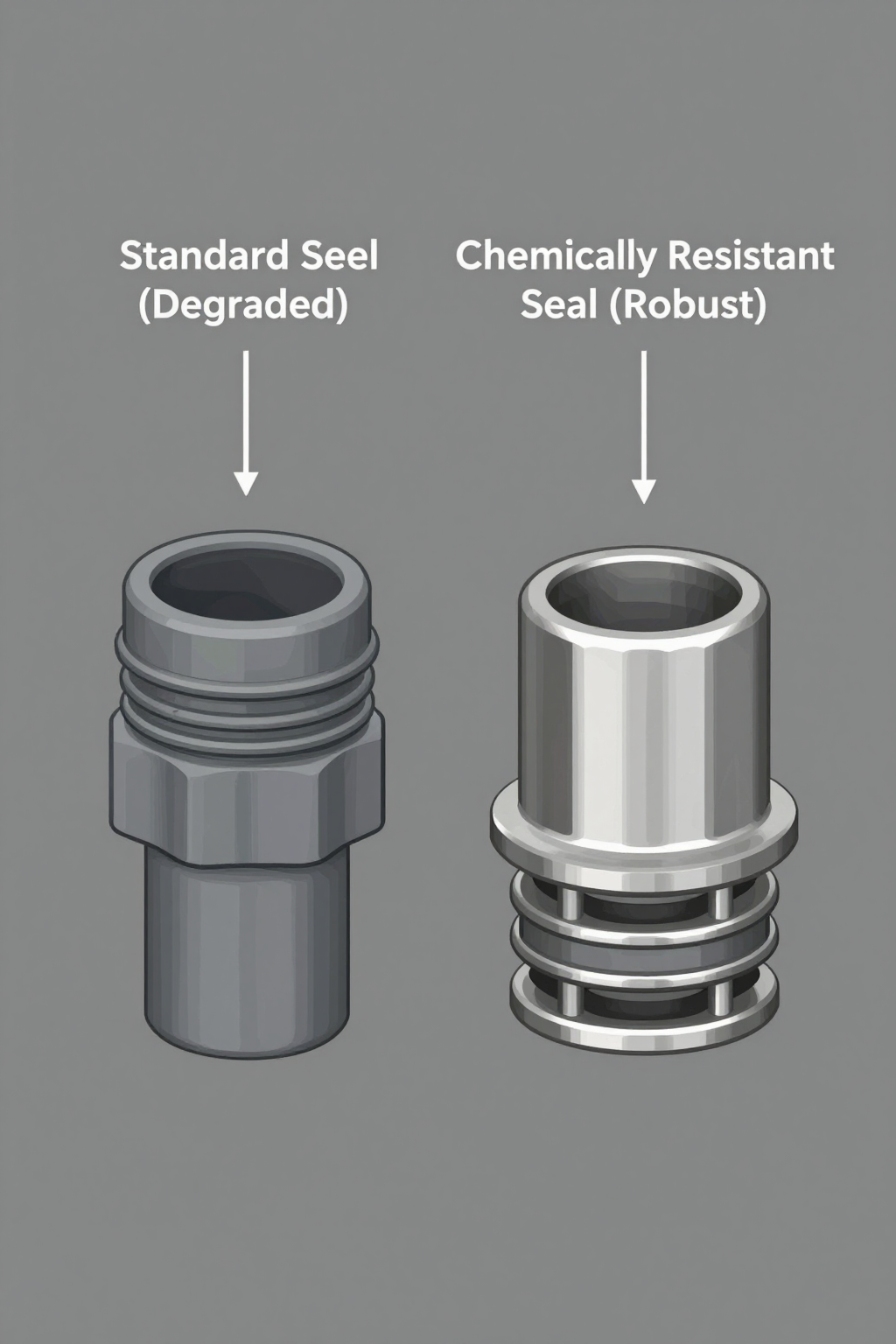

Gate 1: Chemical Exposure Profile

If the deployment involves daily exposure to caustic washdowns, standard thermoplastics typically degrade. In these scenarios, stainless steel housings or specialized high-performance polymers are often required. Engineers must validate that the housing material does not react with the specific facility cleaning agents.

Gate 2: Connection Frequency

If the device requires frequent disconnection for cleaning, a push-pull mechanism or a bayonet lock is generally preferred over threaded couplings. Threaded systems are prone to cross-threading or under-tightening by maintenance staff, which negates the rated ingress protection.

Gate 3: Sealing Redundancy

For critical cooling applications, relying on a single O-ring may be insufficient. Designs featuring overmolded cable assemblies or redundant sealing barriers typically offer higher reliability. If the risk of liquid penetration is high, potting the back of the connector becomes a necessary integration step.

Integration Notes

Proper integration is as vital as component selection. These non-procedural notes highlight common oversight areas:

- Mechanical Orientation: Always install connectors with a drip loop. Mounting connectors facing upwards creates a reservoir for cleaning fluids to pool against the seal, increasing the hydrostatic pressure and risk of ingress.

- Protective Caps: If a connector is left unmated during a washdown cycle, a sealing cap is essential. Without it, the contacts are directly exposed to chemicals and water, leading to immediate degradation.

- Cable Routing: Secure cables to relieve strain on the connector body. Vibration from the cooling unit combined with the weight of a wet cable can compromise the seal interface.

- Maintenance Inspection: Schedule regular visual inspections of the seals. Discoloration or texture changes in the gasket material serve as early warning signs of chemical incompatibility.

FAQ: Common Objections and Clarifications

- Q: Is a standard ingress protection rating sufficient for washdown environments?

Not necessarily. Standard ratings test against water penetration but do not account for chemical degradation of the seals. A high rating is meaningless if the seal material dissolves. - Q: Can we use dielectric grease to improve the seal?

This depends on the specific connector and grease compatibility. While it can help repel moisture, incompatible grease can swell silicone gaskets or attract debris. - Q: Why do metal connectors corrode if they are stainless steel?

Even stainless steel can corrode if exposed to certain chlorides or if the passivation layer is damaged. Selecting the correct grade of stainless steel for the specific chemical environment is crucial. - Q: How does temperature affect cleaning durability?

Cleaning a hot device with cold water creates a pressure differential (vacuum) inside the enclosure, which can suck moisture past the seals. This thermal shock is a common cause of ingress. - Q: Are overmolded cables better than field-attachable connectors?

In washdown environments, overmolded assemblies generally offer superior sealing and strain relief compared to field-attachable versions, which rely heavily on the installer’s skill. - Q: What if the cleaning protocol changes?

Any change in cleaning chemicals requires a re-evaluation of material compatibility. A connector that survives alcohol wipes may fail rapidly under bleach exposure.

Conclusion

Ensuring the longevity of cooling systems in sanitary environments requires a holistic view of the interconnects. It is not enough to select a connector based solely on electrical specs; the chemical and mechanical realities of the cleaning protocol must drive the decision. By focusing on material compatibility, proper strain relief, and sealing redundancy, engineers can prevent common failure modes associated with washdowns.

For applications requiring robust thermal management in these demanding environments, the AlphaCooler Series is designed with these integration challenges in mind.

0 条评论