The environment is rarely forgiving. In a typical foundry or high-volume logistics hub, the air is thick with particulate matter—silica dust, metal fines, or organic fibers—that coats every surface within minutes. The ambient temperature often exceeds the threshold where passive cooling is effective, and the operators are working at a metabolic rate that generates significant internal heat. In this micro-scene, the AlphaCooler unit is not just an accessory; it is a critical component of the safety infrastructure. However, as the shift progresses, a common report emerges: the cooling feels less intense than it did at the start. Is the battery fading? Is the compressor struggling? or is it a simple case of environmental fouling?

For safety managers and operations leads, distinguishing between equipment failure and maintenance drift is the difference between a productive shift and a safety incident. The biggest fear in these deployments is a cooling system that loses performance inversely to the duration of use—failing exactly when the operator is most fatigued. This field note explores the practical realities of maintaining personal cooling systems in hostile environments, focusing on troubleshooting workflows that keep fleets operational without unnecessary downtime.

The Reality of Cooling System Maintenance Field Use

When we discuss cooling system maintenance field use, we are moving beyond the sterile conditions of a testing laboratory into the chaotic reality of industrial deployment. In a controlled environment, airflow is clean, humidity is regulated, and power sources are stable. In the field, these variables fluctuate wildly. A unit that performs flawlessly in the morning briefing room may struggle by the mid-shift break if the intake vents are occluded by a layer of industrial dust. The challenge for the technical buyer or safety lead is to establish a protocol that accounts for these environmental aggressors.

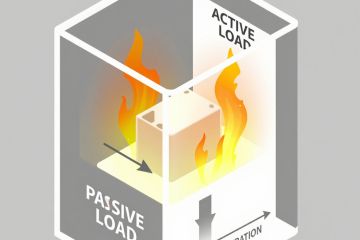

The core of effective maintenance in this context is recognizing that performance degradation is often external, not internal. The AlphaCooler is designed to reject heat, but that rejection requires a clear thermal pathway. When that pathway is obstructed—whether by clothing layers, debris, or positioning—the system must work harder to achieve the same result. This increased duty cycle drains power reserves faster and places higher thermal stress on the components. Therefore, the primary objective of field maintenance is not repair, but the preservation of operating conditions that allow the system to function within its design envelope.

Defining the Maintenance Boundary

It is crucial to define where operator maintenance ends and technician maintenance begins. In many deployments, we see a tendency to over-complicate the operator’s role, leading to frustration and non-compliance. A robust strategy limits the operator’s responsibility to “Go/No-Go” checks—visual inspections of intakes, secure battery insertion, and harness fit—while reserving deeper troubleshooting for the maintenance team. This separation of duties ensures that the cooling system maintenance field use protocols are sustainable and do not encroach on the worker’s primary tasks.

Diagnosing Airflow and Thermal Rejection Constraints

The most common failure mode in personal cooling systems is not a mechanical breakdown, but a thermal suffocation. The AlphaCooler relies on a heat exchanger to transfer thermal energy from the user (or the loop) to the ambient air. This process is governed by the surface area of the condenser and the volume of air moving across it. In environments with high particulate loading, the condenser fins act as an efficient filter, trapping dust and debris. As this layer builds, it acts as an insulator, preventing heat transfer and forcing the compressor to run at elevated pressures.

Symptom Recognition: The “Fade” Effect

Operators often describe a “fade” in cooling power. This is distinct from a sudden shut-off. A fade typically indicates that the system is hitting a thermal limit. If the unit runs continuously but the cooling effect diminishes, the first check should always be the airflow path. Is the intake grill clogged? Is the exhaust port blocked by a safety vest or seat back? In many cases, simply repositioning the unit or wiping down the intake mesh restores performance immediately. This triage step saves significant time compared to swapping batteries or replacing units unnecessarily.

The Particulate Factor

Different environments present different clogging risks. In textile manufacturing, fibrous lint creates a mat that can completely seal an intake. In metalworking, conductive fines can enter the housing if filters are damaged, posing a risk to electronics. Understanding the specific contaminant in your facility allows for tailored maintenance intervals. For high-dust zones, a mid-shift “blow-out” with low-pressure compressed air (if allowed by the IP rating and safety rules) can prevent the thermal runaway that leads to premature battery depletion.

Power Delivery and Connector Hygiene

While airflow is the lungs of the system, power is the blood. In the context of human cooling, the operating environment is inherently humid—not just from ambient conditions, but from the user’s own sweat. Sweat is a saline solution, highly conductive and corrosive. Over time, this moisture can migrate into battery contacts and power connectors, creating resistance that manifests as voltage sag.

Voltage Sag vs. Battery Depletion

A frequent troubleshooting scenario involves a unit that shuts down prematurely, despite the battery indicator showing remaining charge. This is often a symptom of high contact resistance. If the connectors are oxidized or dirty, the voltage drop across the connection increases under load. When the compressor kicks in (drawing peak current), the voltage at the board level dips below the cutoff threshold, triggering a shutdown. To the user, it looks like a dead battery. To the technician, it is a maintenance issue.

Regular inspection of power terminals is essential. Look for:

- Green or white powdery residue (corrosion).

- Pitting on the metal contacts (arcing damage).

- Loose mechanical fit (spring fatigue).

Cleaning contacts with a dedicated electronics cleaner and a stiff brush is often enough to resolve “phantom” battery failures. In fleets where units are shared, this hygiene becomes even more critical, as the wear and tear on connectors is accelerated by frequent mating cycles.

Wearability and Interface Integrity

The AlphaCooler system must interface effectively with the user to provide relief. If the cooling delivery mechanism—whether a vest, fluid loop, or air duct—is compromised, the system’s mechanical performance becomes irrelevant. Field notes often highlight that complaints of “no cooling” are frequently traced to poor fit or kinked delivery lines rather than unit failure.

The Fluid/Air Loop Inspection

For systems utilizing a circulation loop, the integrity of the tubing is paramount. Kinks, pinches, or compression points caused by other PPE (like fall protection harnesses) can restrict flow. A restricted flow reduces the heat transfer rate, making the unit feel ineffective. Troubleshooting here involves a physical inspection of the user’s setup. Is the vest sized correctly? Is the unit mounting compressing the supply line? These are low-tech checks that solve high-impact problems.

Fabric and Hygiene Maintenance

The wearable component absorbs sweat and environmental grime. Over time, salt accumulation in the fabric can affect breathability and thermal conductivity. Moreover, hygiene is a major factor in operator acceptance. A maintenance protocol must include regular laundering or sanitization of the wearable interface, separate from the mechanical unit. Failure to address this often leads to operators refusing to wear the equipment, regardless of the heat stress risk.

Decision Gates: Repair, Refurbish, or Retire

For the operations lead, the ultimate goal of troubleshooting is to make a decision. When a unit is flagged for inspection, a clear decision matrix prevents bottlenecks in the maintenance crib. We recommend a tiered approach to triage.

| Symptom | Primary Check | Secondary Check | Decision |

|---|---|---|---|

| Unit runs, no cooling | Airflow/Intake blockage | Fluid/Air line kinks | Clean/Adjust or escalate to HVAC tech |

| Intermittent shutdown | Battery seating/charge | Connector corrosion | Clean contacts or replace battery |

| No power | Battery status | Fuse/Breaker (if accessible) | Swap unit, tag for repair |

| Excessive noise/vibration | Mounting security | Fan obstruction | Tighten mount or remove debris |

This matrix empowers the field team to resolve simple issues immediately while segregating complex failures for specialized attention. It prevents the “bone pile” effect, where minor issues accumulate until the entire fleet is compromised.

The Psychology of Field Maintenance

One often overlooked aspect of cooling system maintenance field use is the human factor. Operators working in extreme heat are focused on their primary task and their own physical discomfort. They are unlikely to treat the cooling equipment with delicacy. Maintenance protocols must be robust enough to withstand rough handling. Connectors should be keyed and rugged; intakes should be protected by grilles that resist impact.

Furthermore, the reporting culture matters. If an operator fears being blamed for a broken unit, they may hide the failure or continue using a sub-optimal system. Creating a “no-fault” reporting structure encourages early detection of issues. When an operator says, “This isn’t cooling right,” it should be treated as a valid data point for the maintenance team, triggering a proactive check rather than a disciplinary review.

Long-Term Fleet Health Strategies

Managing a single AlphaCooler is simple; managing a fleet of dozens requires a strategy. Rotation is key. If units are used across multiple shifts, they need adequate time to dry out and recharge. Continuous operation without a recovery period can lead to moisture accumulation inside the housing (condensation) which eventually attacks the electronics.

Storage Environment: Storing units in a damp, unventilated locker promotes mold growth and corrosion. A dedicated charging station with good air circulation ensures that units dry out between uses, extending the life of both the electronics and the wearable textiles.

Spare Parts Inventory: Analysis of field failures typically reveals a Pareto distribution—a few small parts cause the majority of downtime. Consumables like intake filters, O-rings, and battery contacts should be stocked locally. Waiting weeks for a minor component effectively removes a safety device from the floor, increasing risk.

Frequently Asked Questions

How often should the intake filters be cleaned?

This depends entirely on the environment. In a clean assembly area, weekly checks may suffice. In a foundry or sanding booth, daily or even mid-shift cleaning may be necessary to maintain peak performance.

Can we use standard compressed air to clean the units?

Typically, yes, but caution is required. High-pressure air can damage cooling fins or force dust deeper into sealed bearings. Use low-pressure air and direct it outward, away from the internals, to dislodge surface debris.

Why does the unit feel hot to the touch?

The unit is a heat pump; it moves heat from the user to the unit’s exhaust. The exterior housing, particularly near the exhaust vents, will become warm during operation. This is normal. However, if it becomes too hot to touch safely, it indicates a lack of airflow or an internal fault.

Is it safe to swap batteries while the unit is running?

Consult the specific operating manual, but generally, it is best practice to power down the unit before removing the power source to prevent arcing at the contacts and potential data corruption in the control logic.

What is the expected service life of the wearable vest?

The wearable component is a consumable. Its life depends on the frequency of washing and the abrasiveness of the outer clothing. Regular inspection for leaks or fabric thinning is required to ensure it continues to deliver cooling effectively.

Integration Support

Every industrial environment has a unique thermal and contaminant profile. If your deployment faces specific constraints—such as conductive metal dust, extreme ambient humidity, or unique mounting requirements—standard maintenance intervals may need adjustment. We can review your operational conditions and help define a tailored support strategy that aligns with your safety goals and shift structures.

0 条评论