Field Snapshot: An industrial safety team invests in a powerful, stationary liquid chiller to support their crew’s personal cooling vests during strenuous maintenance tasks in a high-heat environment. The goal is to extend work duration and reduce heat stress risk. After connecting the system, the feedback is underwhelming. The vests feel cool to the touch, but operators report that the cooling effect is weak and fades quickly. The initial assumption is that the vests themselves are the issue. However, a closer look at the integration reveals the true culprit: the system’s fluid dynamics are starving the vest of the flow it needs to be effective.

This scenario is common. In many deployments, the focus is placed entirely on the chiller’s temperature output, while the equally critical factor of fluid flow rate is overlooked. A cooling vest is a heat exchanger, and its efficiency is fundamentally tied to the volume of chilled fluid passing through its micro-tubing per unit of time. When that flow is compromised, performance suffers, regardless of how cold the coolant is at the source.

Understanding Cooling Vest Flow Rate Real-World Performance

When we discuss cooling vest flow rate real-world performance, we’re moving beyond simple temperature specifications and into the realm of dynamic thermal management. It’s not enough for a chiller to produce cold water; it must deliver that water to and through the vest at a rate sufficient to absorb and carry away the operator’s metabolic heat load. Think of it as the difference between a slow-moving, cold stream and a fast-moving, cool river. The river’s volume and speed give it a far greater capacity to absorb and transport heat.

In a personal cooling system, several factors create resistance, collectively known as ‘system head’ or ‘pressure drop.’ The pump inside the chiller must overcome this total resistance to maintain adequate flow. This resistance doesn’t come from just one place; it’s the sum of friction losses from the hose walls, turbulence from fittings and connectors, and the gravitational force the pump must fight if it’s lifting the fluid vertically.

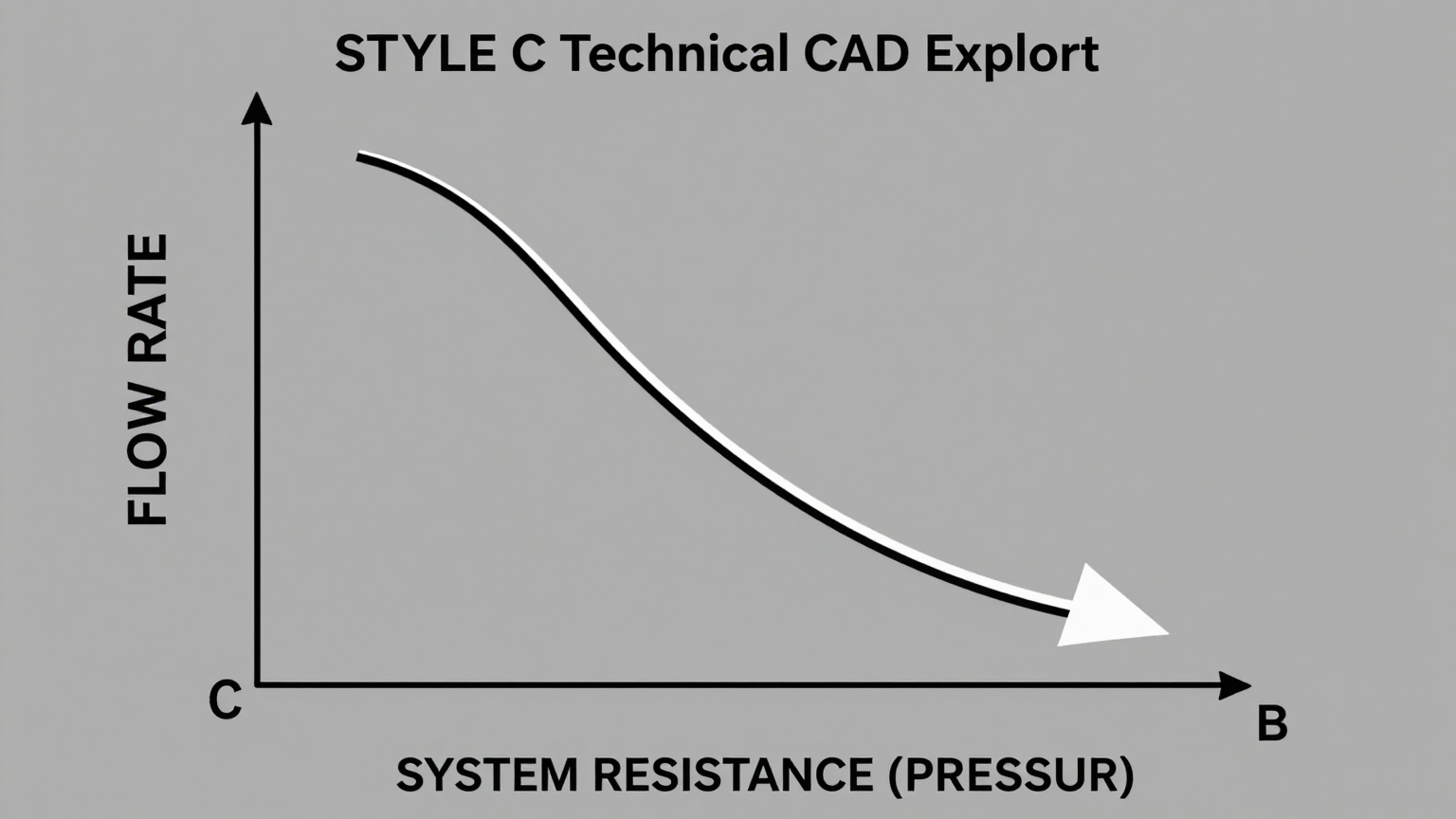

A common point of confusion is the difference between pressure and flow. A pump might be rated for a high static pressure, but if the system resistance is also high, the resulting flow rate can be disappointingly low. The real-world performance of any integrated cooling vest system is therefore a delicate balance between the pump’s capability and the total hydraulic resistance of the circuit connecting it to the wearer.

Common Pitfalls That Degrade Flow Rate in Integrated Systems

The performance gap between the lab and the field often comes down to the physical connections and layout of the system. Each component added to the fluid path introduces a potential point of failure or inefficiency that can choke the flow rate. Identifying these potential issues during the design and integration phase is critical for success.

Hose Diameter and Material Selection

One of the most frequent and impactful errors is selecting an undersized hose diameter. A small reduction in diameter dramatically increases fluid friction and, consequently, the pressure required to move the same volume of liquid. This forces the pump to work harder, often pushing it into an inefficient part of its performance curve, which results in a lower flow rate. While smaller hoses may be lighter or easier to manage, the performance trade-off can be severe. It’s often better to accommodate a slightly larger hose to ensure the vest receives the intended flow.

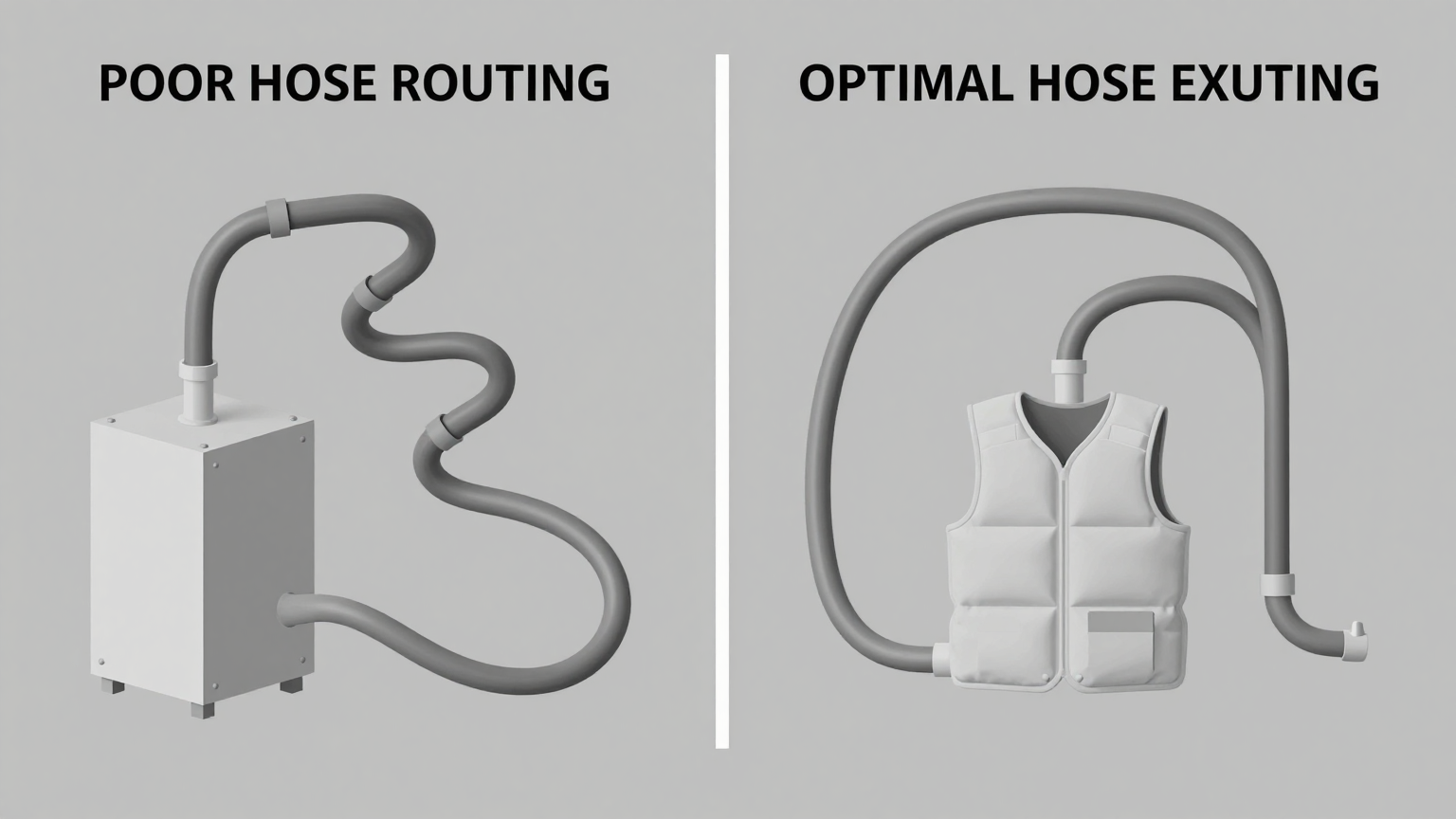

Hose material is also a key consideration. Hoses that are too soft or not reinforced can be prone to kinking or even collapsing under negative pressure, especially around tight bends. This creates a near-total blockage, effectively stopping the cooling effect. A rigid or semi-rigid, kink-resistant hose material is typically a better choice for demanding industrial applications.

The Impact of Hose Length and Vertical Lift

Every foot of hose adds to the total system resistance. In scenarios where the chiller unit is placed far from the operator, long hose runs can accumulate significant friction losses. A system that works perfectly with a short test hose on a bench can fail to perform when deployed with a much longer umbilical in the field. The rule of thumb is to keep the hose length as short as the operational requirements will practicably allow.

Furthermore, if the chiller is on the floor and the operator is working on a platform several feet above it, the pump must constantly work against gravity to lift the coolant. This ‘head pressure’ is a direct addition to the system’s total resistance. A pump that can easily circulate fluid on a level plane may struggle to provide adequate flow when a significant vertical lift is introduced.

Quick-Disconnects and Fittings as Flow Restrictors

Quick-disconnect (QD) fittings are essential for usability, but they are also significant sources of flow restriction. The internal valves and complex pathways within these connectors create turbulence, which impedes flow. Using more QDs than necessary or selecting a type with a restrictive internal design can cumulatively degrade performance. The same applies to sharp 90-degree elbow fittings. While sometimes necessary for routing, each one adds more resistance than a gentle, sweeping bend in the hose itself. Minimizing the number of fittings is a core principle of efficient hydraulic design.

Diagnosing Flow-Related Issues in the Field

When a cooling vest system underperforms, a systematic approach to troubleshooting can quickly isolate the root cause. Before blaming the vest or the chiller, investigate the circulatory system that connects them.

Symptom: The vest provides an initial sensation of cold, but the operator feels warm again within minutes, especially under exertion.

- Initial Check (Visual Inspection): Trace the entire length of the hose from the chiller to the vest. Look for visible kinks, sharp bends, or points where the hose might be compressed or flattened. This is the most common and easily corrected failure mode.

- Secondary Check (Tactile Test): Carefully feel the inlet and outlet hoses near the vest. In a high-flow system, the temperature difference might be subtle. A very large and noticeable liquid cooling vest temperature differential between the two hoses can sometimes indicate that the fluid is moving too slowly, allowing it to absorb a great deal of heat before returning to the chiller.

- Auditory Check (Pump Health): Listen to the pump. A healthy pump should have a consistent, smooth hum. A loud whining, grinding, or intermittent buzzing sound can indicate that it is straining against excessive back-pressure (a restriction) or cavitating due to an airlock or fluid starvation.

- System Purge (Airlock Detection): Airlocks are pockets of trapped air that can stop fluid circulation entirely. They often form at high points in the hose line. Gurgling sounds from the pump or reservoir are a classic sign. To resolve this, you typically need to purge the system by running the pump while manipulating the hoses to encourage the air bubbles to move towards the reservoir.

Pump Selection and System Matching

The pump is the heart of the cooling system. Integrating a chiller for a cooling vest requires ensuring the chiller’s internal pump is properly matched to the demands of the entire system, not just the vest itself. A pump that is perfectly adequate for circulating fluid within a self-contained unit may be undersized for an application involving long hoses and multiple connectors.

Engineers refer to a ‘pump curve,’ a graph that shows how a pump’s flow rate output changes as system resistance (pressure) increases. Every pump has a point where, as resistance gets too high, its flow rate drops to nearly zero. The goal of system integration is to ensure that the total resistance of your hoses, fittings, vertical lift, and the vest itself falls within a range where the pump can still deliver a high flow rate. This is why simply looking at a pump’s maximum pressure rating is not enough; you must consider the flow rate it can deliver at your system’s specific operating pressure.

Frequently Asked Questions (FAQ) about Cooling Vest Integration

Addressing common questions can help clarify the system-level thinking required for successful deployments.

| Question | Field Notes |

|---|---|

| Why does the vest feel cold, but I still feel hot? | This often points to insufficient flow. The coolant is cold, but it’s not moving through the vest fast enough to remove your metabolic heat load. The system lacks the thermal carrying capacity, which is a direct function of flow rate. |

| Can I use any type of hose with my system? | This is not recommended. Hose material, reinforcement, and internal diameter are critical design parameters. Using an incompatible hose can lead to kinking, chemical incompatibility with the coolant, or excessive pressure drop that cripples performance. |

| Is a noisy pump a sign of a problem? | It can be. A pump that is ‘cavitating’ (sounds like it has gravel in it) is often struggling with an airlock or a flow restriction. A high-pitched whine can indicate the pump is straining against too much back-pressure. Both symptoms point to flow-related issues that need investigation. |

| How can I tell if I have an airlock? | Intermittent cooling, gurgling sounds from the pump or reservoir, and a pump that sounds like it’s running erratically are common signs. The solution is to purge the system by manipulating the hoses to guide the air pocket back to the reservoir. |

| Does the type of coolant fluid affect flow rate? | Yes. Fluids have different viscosities (thickness), which affects how easily they can be pumped. Using a fluid that is more viscous than what the system was designed for will increase resistance and reduce flow. Always use the manufacturer-recommended coolant. |

| Is higher cooling vest pump pressure always better? | Not necessarily. The objective is an optimal flow rate. Extremely high pressure can put unnecessary strain on hoses, fittings, and vest seams without a proportional increase in cooling. The goal is to match the pump’s capabilities to the system’s resistance to achieve the target flow. |

Integration Support

The performance of a personal cooling vest is inseparable from the quality of its integration. The principles of fluid dynamics—pressure, resistance, and flow—are as critical as the principles of thermodynamics. A successful deployment is a systems-level achievement where the chiller, the fluid transport (hoses/fittings), and the heat exchanger (the vest) are all designed to work in concert.

If your operational constraints present unique integration challenges, such as extended hose lengths or significant vertical lift requirements, our engineering team can review your platform’s specific architecture. We can help align on a configuration path that avoids common pitfalls and ensures the system delivers its full thermal management potential. A thoughtful approach to integration ensures that the focus remains on operator safety and performance, not on troubleshooting equipment in the field.

0 条评论