Field Snapshot: The telemetry from the last stint is clear. After the thirty-minute mark, steering inputs become less precise and lap times begin to drift. The driver reports diminished concentration as cockpit temperatures climb, a classic case of cumulative heat soak. The current ice-based cooling system is depleted long before the pit window, making it ineffective for endurance applications. A continuous, ice-free cooling solution is required to maintain driver performance and safety for the full duration of the event.

Considerations for a racing driver cooling system no ice

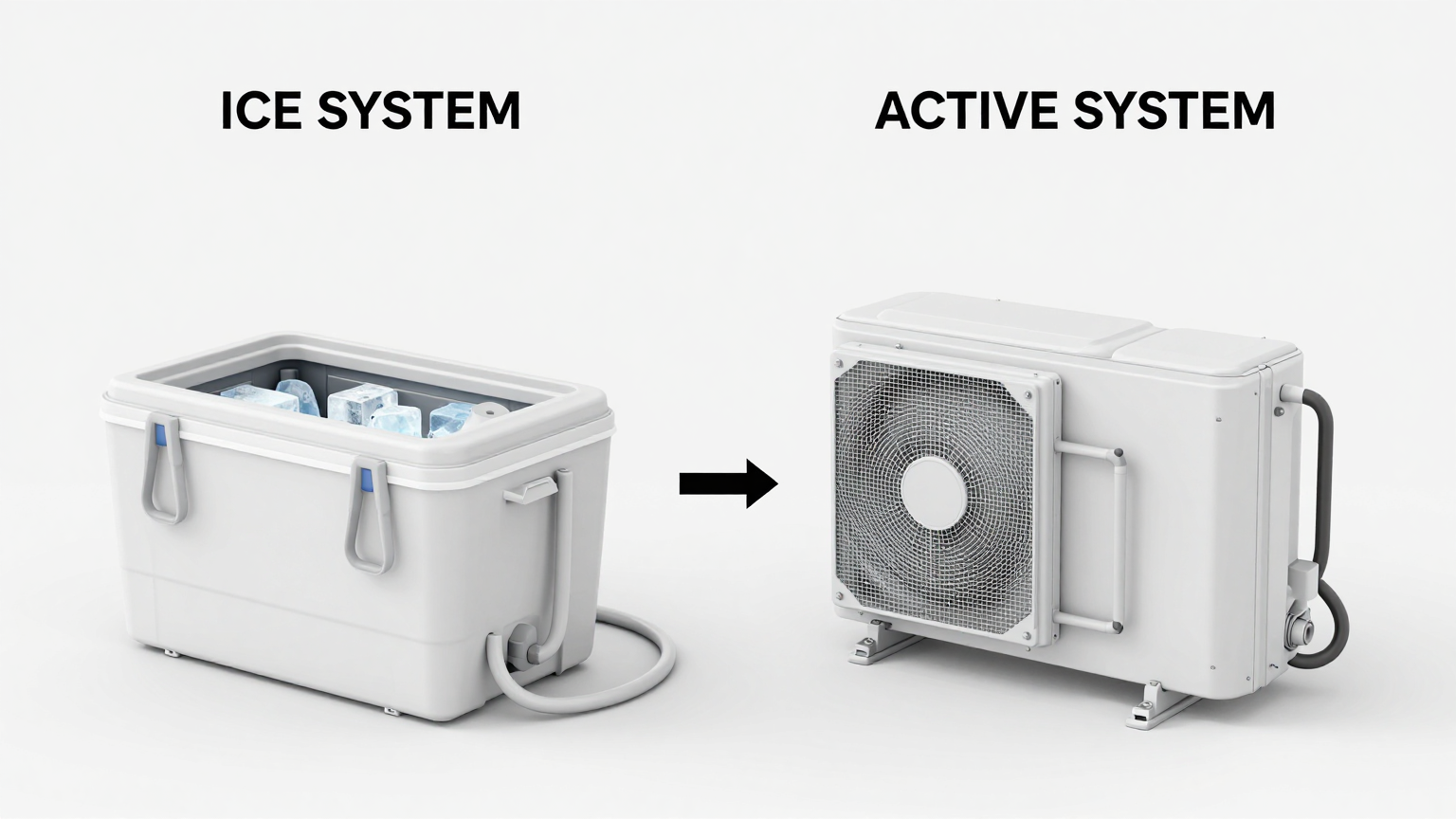

The transition from traditional ice-and-water circulation systems to an active, vapor-compression solution represents a significant shift in thermal management strategy. While ice-based systems are mechanically simple, their performance is inherently finite and inconsistent. Their cooling capacity degrades non-linearly as the ice melts, and they impose a considerable logistical burden on the crew for sourcing, transporting, and handling ice during a race weekend. For endurance events, where sustained driver performance is paramount, the limitations of ice-based cooling often become a critical performance bottleneck.

An active, or ‘no-ice’, system leverages vapor-compression refrigeration to provide a continuous and consistent supply of chilled fluid to the driver’s cooling garment. This approach eliminates the dependency on consumables like ice, offering a predictable and sustainable cooling solution. However, this capability introduces a new set of engineering constraints that must be thoroughly evaluated. The decision to integrate such a system is not merely a component swap; it is an exercise in system-level engineering that touches the vehicle’s electrical architecture, weight distribution, and overall packaging. A successful deployment depends on a clear understanding of these trade-offs and a rigorous approach to integration.

Initial Triage: Is an Active Cooling System Viable for Your Application?

Before committing to an active cooling architecture, a series of triage checks can determine its feasibility within the context of a specific vehicle and racing series. These checks focus on the fundamental resources the system will demand: electrical power, physical space, and its alignment with the event’s thermal load profile.

Power Budget Analysis

The first and most critical gate is the vehicle’s electrical capacity. An active cooling system is a significant electrical load, drawing a continuous current to run its compressor and pumps. The central question is whether the vehicle’s alternator and battery system can support this additional load without compromising other critical systems. This analysis involves:

- Assessing Alternator Headroom: The alternator must be able to supply the current required by the cooling system on top of all other existing loads (ECU, fuel pumps, data logging, communications, lighting). Operating an alternator at its maximum rated output for extended periods can reduce its lifespan and reliability. There should be sufficient overhead in the system.

- Evaluating Battery Role: In many motorsport applications, the battery acts as a buffer for transient loads. It’s important to understand if the cooling system’s draw will excessively discharge the battery during low-RPM periods, such as under caution flags or in pit lane, potentially affecting the vehicle’s ability to restart.

- Wiring and Circuit Protection: The integration plan must include a dedicated, fused circuit for the cooling system. The wire gauge must be appropriately selected to handle the current draw over the required distance without significant voltage drop, and all connectors should be of a high-quality, vibration-resistant type common in motorsport.

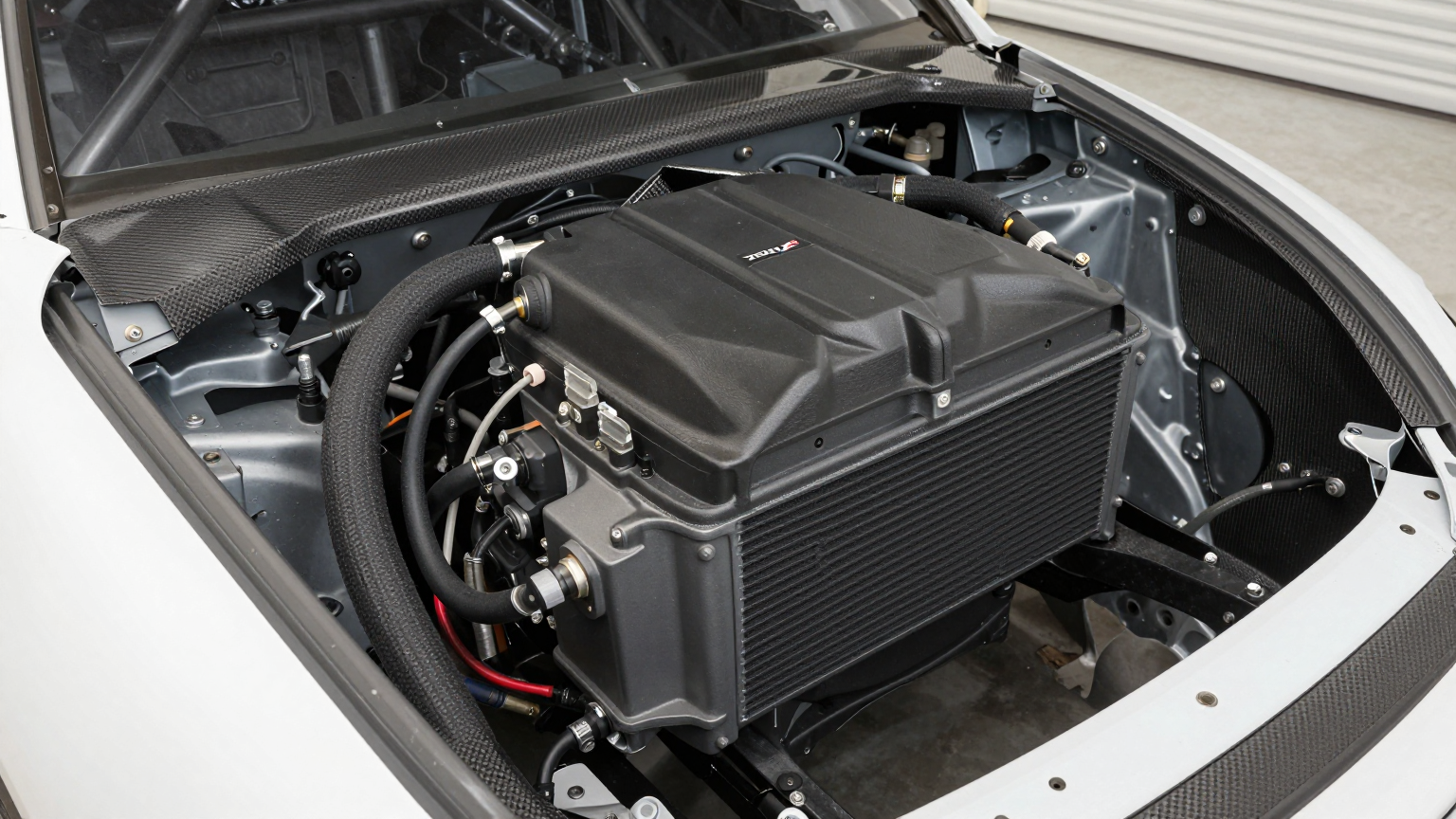

Space Claim and Weight Distribution

A racing vehicle is a tightly packaged environment where every cubic inch and every pound is scrutinized. An active cooling system, with its compressor, condenser, and associated plumbing, requires a dedicated physical space. Key considerations include:

- Component Placement: The main unit needs to be mounted securely in a location that does not interfere with driver ergonomics, safety structures, or other vehicle systems. Common locations, such as the passenger footwell or a section of the trunk, must be evaluated for available volume.

- Mass and Center of Gravity: The weight of the system, while often modest, must be factored into the vehicle’s weight and balance calculations. The placement of the mass can influence handling dynamics, and it’s a common practice to position such components as low and as centrally as possible.

- Condenser Location: This is a critical factor for performance. The condenser is the system’s heat exchanger to the ambient air. It requires a steady supply of airflow to function effectively. Its placement must be considered in the context of the vehicle’s aerodynamics, ensuring it is in a location with adequate flow while being protected from track debris.

Thermal Load Profile Alignment

The type of racing dictates the thermal challenge. A short sprint race imposes a different load than a multi-hour endurance event. An active system is typically best suited for scenarios where cooling is needed for long, uninterrupted durations. If the primary challenge is a short burst of heat, the complexity of an active system might not be justified. However, for endurance racing, where heat soak is cumulative and driver changes are part of the strategy, a system that can run continuously for hours, independent of pit stops, provides a decisive advantage.

Common Failure Modes of Inadequate Cooling Strategies

Understanding how cooling systems fail in the field is essential for designing a robust solution. The failure modes differ significantly between ice-based and active systems, and each presents a unique set of risks to driver safety and performance.

Ice-Based System Depletion and Inconsistency

The most common failure mode of an ice-based system is predictable: it runs out of ice. The cooling is not delivered at a constant rate; it peaks early and then tapers off as the ice melts and the water temperature rises. This creates an inconsistent thermal environment for the driver. Furthermore, the logistical chain is a frequent point of failure. Sourcing sufficient quantities of quality block ice at a race track can be difficult, and the process of draining, refilling, and managing coolers during a pit stop adds complexity and time to the stop.

Active System Thermal Overload

An active system’s performance is contingent on its ability to reject heat through its condenser. If the condenser’s airflow is blocked by debris (like rubber marbles or leaves) or if it is installed in an area of stagnant air, the system cannot shed heat effectively. This causes refrigerant pressures and temperatures to rise, leading to a protective shutdown of the compressor. The result is an intermittent or complete loss of cooling. This failure mode is not about a consumable being depleted but about improper system integration—a critical distinction.

Power System Faults and Interconnect Failures

Given their reliance on the vehicle’s electrical system, active coolers are vulnerable to power supply issues. A primary failure point is often the electrical connectors. In a high-vibration motorsport environment, standard automotive connectors can work themselves loose or suffer from fretting corrosion, leading to an intermittent or open circuit. An undersized wire gauge can lead to excessive voltage drop, causing the unit to underperform or fail to start. A fault in the vehicle’s charging system, such as a failing alternator, will also quickly disable the cooling system along with other essential electronics.

Coolant Flow and Garment Integration Issues

The cooling system does not end at the unit’s outlet port; it extends through the hoses and the driver’s cooling garment. The garment itself is the final and most critical heat exchanger. A failure in this part of the circuit renders the entire system useless. Common failure modes include:

- Kinked Hoses: Improperly routed hoses can easily become kinked or pinched by the driver’s seat belts or seating position, restricting or completely blocking coolant flow.

- Leaking Quick-Disconnects: The fittings that connect the driver to the car are cycled frequently and can wear over time, leading to leaks that are both a performance issue and a distraction.

- Inefficient Garment: A low-quality cooling shirt with sparse tubing or poor thermal conductivity will not effectively transfer heat from the driver’s body to the chilled fluid, even if the fluid is at the optimal temperature. The garment must be considered an integral performance component of the system.

Tradeoffs and Decision Framework: Ice vs. Active Systems

Choosing the right cooling strategy involves a careful evaluation of competing constraints. There is no single solution that is superior in all contexts. The optimal choice depends on the specific demands of the racing series, the vehicle platform, and the team’s operational capabilities. The AlphaCooler line of products provides an active cooling solution designed for these demanding environments, but the decision to adopt it requires a clear-eyed assessment of the following trade-offs.

| Decision Constraint | Ice-Based System Characteristics | Active (No-Ice) System Characteristics |

|---|---|---|

| Cooling Consistency | Inconsistent. Performance degrades as ice melts. | Consistent. Provides stable cooling output as long as power is supplied. |

| Operational Duration | Finite. Limited by the amount of ice in the cooler. | Continuous. Limited only by vehicle runtime and power availability. |

| Logistical Burden | High. Requires sourcing, storing, and handling ice at the track. | Low. Self-contained system with no consumables. |

| System Complexity | Low. Typically just a pump, cooler, and hoses. | High. Involves a compressor, condenser, evaporator, and control electronics. |

| Power Demand | Low. Only requires power for a small circulation pump. | High. Requires significant, continuous current for the compressor. |

| Integration Challenge | Simple. Largely a self-contained, portable unit. | Complex. Requires careful integration with vehicle electrical and mechanical systems. |

| Maintenance Profile | Minimal. Primarily involves cleaning and checking the pump. | Requires periodic checks of electrical connections, condenser fins, and fluid levels. |

Integration Checklist for Active Cooling Systems

This is not an installation manual but a checklist of critical thinking points for system integrators and race engineers. A successful integration is one that is reliable, serviceable, and effective.

Electrical System Integration

- Dedicated Circuit: Has a dedicated, properly fused circuit been established for the cooling system?

- Wire Gauge and Length: Is the wire gauge sufficient for the current draw and the total length of the run to prevent voltage drop?

- Connector Specification: Are motorsport-grade, positive-locking, and vibration-resistant connectors used for all connections?

- Alternator Capacity: Has the total vehicle electrical load, including the new cooling system, been calculated and confirmed to be within the alternator’s sustained output capacity?

Mechanical Mounting and Vibration Isolation

- Secure Mounting Points: Is the unit mounted to a structurally sound part of the chassis?

- G-Force Bracing: Will the mounting solution withstand the high G-forces of braking, acceleration, and cornering?

- Vibration Dampening: Are vibration-isolating mounts used to protect the unit’s internal components and prevent the transmission of vibration into the chassis?

Thermal Management of the System

- Condenser Airflow Path: Is the condenser placed in a location that will receive consistent, high-volume airflow when the vehicle is in motion?

- Heat Source Isolation: Is the condenser and its associated lines shielded from radiant heat sources like the engine exhaust or brakes?

- Debris Protection: Is the condenser protected from direct impacts and clogging from track debris by a screen or strategic placement?

Fluid Dynamics and Garment Compatibility

- Hose Routing: Are the fluid hoses routed to avoid pinching, kinking, and abrasion? Are they clear of moving parts and sharp edges?

- Quick-Disconnects: Are the quick-disconnect fittings high-quality and easily accessible for the driver and crew?

- Garment Selection: Is the driver’s cooling garment compatible with the system’s flow rate and designed for efficient thermal transfer?

- Pre-Race Flow Check: Is a system flow check part of the pre-session preparation checklist?

Frequently Asked Questions (FAQ)

How does ambient temperature affect system selection?

Higher ambient temperatures place a greater thermal load on both the driver and the cooling system. While an ice-based system’s performance is largely independent of ambient air temperature (it depends on the ice), its duration will be shorter as the driver requires more cooling. An active system’s performance is directly tied to the condenser’s ability to reject heat into the ambient air. In very hot conditions, ensuring adequate airflow to the condenser is even more critical for an active system to maintain its cooling capacity.

What is the primary electrical consideration for an active system?

The primary consideration is the alternator’s ability to handle the continuous current draw. Unlike intermittent loads, the cooling system’s compressor runs for long periods, representing a significant and sustained demand on the vehicle’s charging system. A thorough power budget analysis is the most important step in the electrical integration process.

How does race duration influence the choice between ice and active cooling?

Race duration is one of the strongest factors. For short sprint races, a well-prepped ice box may provide sufficient cooling. For any event lasting longer than the lifespan of a single charge of ice, the logistical complexity and performance inconsistency of ice systems become significant liabilities. Active systems excel in endurance scenarios where continuous, reliable cooling is needed for multiple hours.

What are the signs of an undersized or improperly installed active cooling system?

The most common sign is a gradual loss of cooling performance as the system and cockpit heat soak. The driver may report that the system feels cool initially but cannot keep up as the race progresses. Another sign is intermittent cooling, where the system seems to cycle on and off; this can be an indication that the compressor is hitting a thermal or pressure limit due to inadequate condenser airflow.

What are the key maintenance differences between systems?

Ice-based systems require constant operational support (draining, cleaning, refilling) but little long-term maintenance. Active systems require minimal track-side support during an event but benefit from periodic maintenance. This includes inspecting electrical connectors for tightness and corrosion, cleaning the condenser fins of any accumulated debris, and checking fluid connections for any signs of leaks.

How critical is condenser placement?

It is arguably the most critical factor for the performance of an active system. The entire system’s ability to remove heat from the driver is dependent on the condenser’s ability to expel that heat into the atmosphere. A poorly placed condenser with insufficient airflow will cripple the performance of even the most powerful system.

What role does the driver’s cooling garment play?

The garment is not an accessory; it is an integral part of the cooling system’s heat transfer circuit. The surface area covered by the cooling tubes, the material of the shirt, and its fit against the driver’s skin all dictate how efficiently heat can be extracted. Pairing a high-performance active cooling unit with a low-quality garment will result in a significant performance bottleneck.

0 条评论