Field Snapshot: When Passive Methods Fail in Active Cooling for Sealed 5G Cabinets

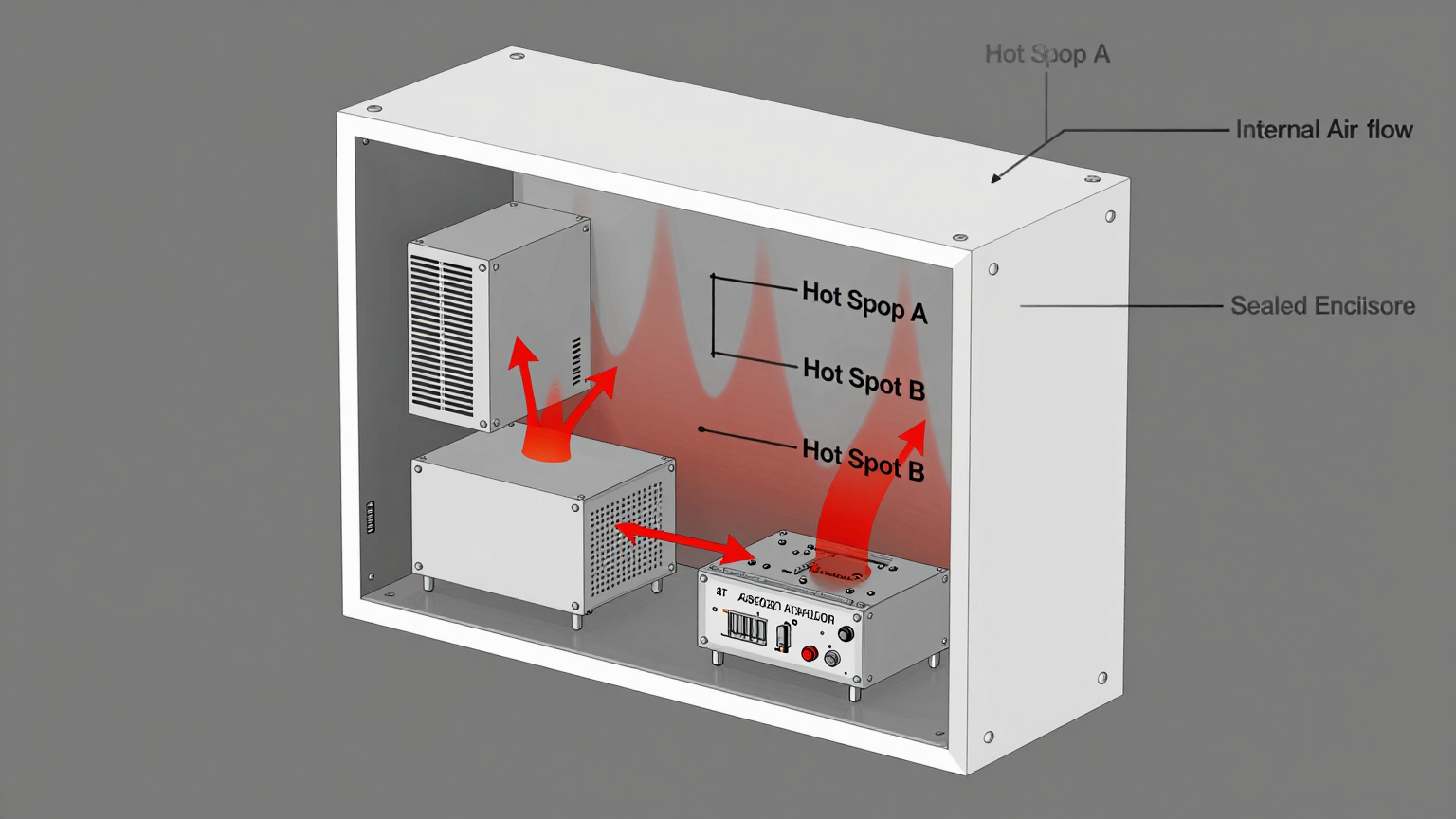

We were on a call about a rooftop 5G deployment. The scenario is common: a sealed telecom cabinet is hitting its thermal limits on summer afternoons, causing intermittent connectivity drops for users. The OEM’s own logs pointed to thermal throttling. A look at the cabinet’s internal layout showed known hot spots around the power supply and the main radio unit, where heat was pooling despite internal circulation fans. The existing air-to-air heat exchanger just couldn’t keep up once the ambient temperature peaked, especially with direct solar load on the enclosure. The core engineering problem wasn’t just total heat load, but the inability of the current system to keep component temperatures stable and below ambient when necessary. This post documents the decision process for moving from passive or insufficient methods to a more robust solution. By the end, you’ll have a clear framework for identifying the specific constraints that make miniature compressor-based systems a necessary upgrade.

First Checks from the Field Notebook

Before specifying a new thermal management system, we run through a few primary checks. These initial data points quickly frame the problem and rule out simpler, less effective fixes.

- Check: Maximum Ambient Temperature vs. Required Internal Temperature. Why: This is the fundamental thermal challenge. We need to know if the system must operate below the outside air temperature. What it suggests: If the required internal operating temperature is close to or, more critically, below the peak ambient temperature, passive solutions like heat exchangers are immediately on shaky ground. They rely on a temperature differential that may not exist during a heatwave.

- Check: Enclosure Seal Requirements (IP Rating). Why: Sealed enclosures protect sensitive electronics from dust, moisture, and corrosive elements, which is critical in outdoor or industrial deployments. What it suggests: A high IP rating (e.g., IP65+) is a hard constraint that typically eliminates direct air cooling. Any solution that requires venting outside air into the cabinet is a non-starter, pushing the decision toward closed-loop systems.

- Check: Internal Heat Load and Hot Spot Mapping. Why: The total heat load in watts is only part of the story. A 300W load concentrated in one small area is a much harder problem than the same load distributed evenly. What it suggests: If specific components are throttling while the cabinet’s average internal temperature seems acceptable, the problem is airflow and targeted cooling. This points to a solution that can not only remove the total heat but also direct cooled air precisely where it’s needed most.

Common Failure Modes & Constraints

When a cabinet’s thermal design is mismatched to its environment, the symptoms are often mistaken for component or software issues. Here are the patterns we see in the field.

- Symptom: Intermittent service drops, especially between 1 p.m. and 5 p.m. on sunny days. Likely Cause: A combination of peak solar load on the cabinet and high network usage drives component temperatures past their throttle point. Why it matters: This directly impacts service reliability and customer satisfaction.

- Symptom: Premature failure of power supplies, transceivers, or processors. Likely Cause: Sustained operation at temperatures exceeding the manufacturer’s recommended limits. Even if not throttling, long-term heat exposure degrades electronics. Why it matters: This increases OpEx through frequent, costly truck rolls and hardware replacements.

- Symptom: Fans running at 100% duty cycle, yet internal temperatures continue to climb. Likely Cause: The existing thermal solution (e.g., a heat exchanger) has reached its maximum heat transfer capacity. It simply cannot move any more energy out of the box. Why it matters: It’s a clear sign the current system is undersized for the real-world thermal load.

- Symptom: Evidence of moisture or condensation inside a supposedly sealed cabinet. Likely Cause: An improperly implemented cooling system can create cold surfaces that cause ambient humidity to condense, or a failing seal is letting humid air in. Why it matters: Moisture is a primary vector for corrosion and short circuits.

- Symptom: System performance is noticeably worse on hot, clear days compared to milder, overcast days. Likely Cause: High solar gain is adding a significant, unaccounted-for thermal load to the exterior of the cabinet. Why it matters: This confirms the problem is environmental and requires a cooling solution that can actively combat external heat sources, not just dissipate internal ones.

Decision Gates for Specifying Active Cooling

Moving to a compressor-based system isn’t the first step, but certain engineering constraints make it the logical conclusion. We see three main decision gates that push a design toward this type of active cooling for sealed 5G cabinets.

Gate 1: The Sub-Ambient Requirement

- Constraint: The internal electronics must be maintained at a temperature below the maximum expected external ambient temperature. For many high-performance electronics, this is a firm requirement for stability.

- Decision Trigger: Air-to-air heat exchangers and simple fan-and-heatsink setups cannot, by definition, cool below ambient. Their effectiveness diminishes to zero as the internal-to-external temperature difference shrinks.

- Engineering Resolution: A vapor-compression refrigeration cycle is required. This is the only practical technology that uses a refrigerant to actively pump heat out of the enclosure, achieving an internal temperature lower than the outside air.

- Integration Trade-off: This approach consumes more power than a passive heat exchanger and introduces higher system complexity, but it meets the core technical requirement that others cannot.

Gate 2: The Sealed Enclosure Mandate

- Constraint: The cabinet must maintain a high IP rating (e.g., IP65, IP66) to protect against dust, water, and other environmental contaminants.

- Decision Trigger: Direct air cooling, which uses fans to pull outside air through filters, fundamentally compromises the enclosure’s seal. Filter maintenance and potential ingress of fine dust or moisture are persistent problems.

- Engineering Resolution: A closed-loop cooling system is necessary. A miniature DC air conditioner integrates into the cabinet wall, removing internal heat while keeping the internal and external air paths completely separate, thus preserving the seal.

- Integration Trade-off: Requires careful mechanical integration to ensure a proper seal around the unit and a plan for managing condensate from the evaporator coil.

Gate 3: The High Heat Flux or Density Gate

- Constraint: The total heat load from components and solar gain, often in the 100W to 550W range for these applications, is too high for other sealed-box technologies.

- Decision Trigger: Thermoelectric coolers (TECs) are solid-state but suffer from low efficiency, especially with high heat loads or at high ambient temperatures (e.g., above 55°C). They become impractically large and power-hungry.

- Engineering Resolution: A miniature DC compressor system provides a much higher cooling capacity for its size and power budget. The ability to dynamically adjust compressor speed also allows it to match the cooling rate to the actual load, improving efficiency.

- Integration Trade-off: Introduces the mechanical components of a compressor, which requires consideration for vibration and mounting orientation.

Integration Notes: Beyond the Spec Sheet

Specifying the right cooling unit is half the battle. Successful integration requires a holistic view of the system.

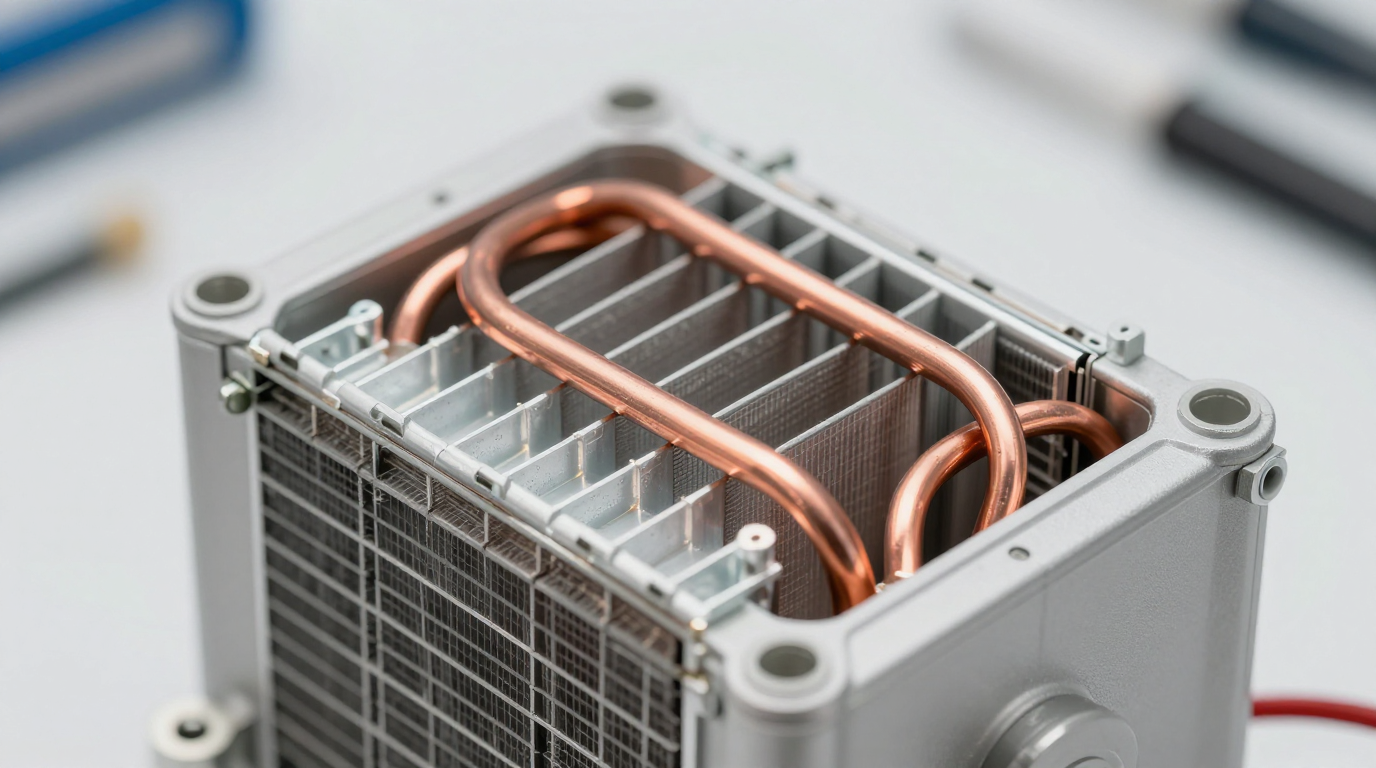

- Mechanical: Plan for vibration dampening. Even small compressors have moving parts, and isolation grommets can prevent vibration from affecting sensitive electronics. Condensate management is non-negotiable; ensure there’s a clear path for drainage or an integrated method for evaporation.

- Electrical: These systems are designed for DC power, typically in the 12V to 48V range, making them a good fit for standard telecom power plants. However, you must budget for the power consumption, which can range from 50W to 350W depending on the load. Ensure your power supply can handle both the steady-state draw and any brief inrush current on startup.

- Thermal: This is the most critical part. Simply installing an AC unit isn’t enough. You must engineer the internal airflow to pull hot air from the key components (the radio, the PSU) into the evaporator (cold side) and distribute the cooled air effectively. On the outside, the condenser (hot side) must have unrestricted airflow and should not be placed where it can re-ingest its own hot exhaust.

- Maintenance: In a sealed, closed-loop system, internal components stay clean. However, the external condenser coils can accumulate dust and debris, which will degrade performance over time. Plan for periodic inspection and cleaning as part of the site’s regular maintenance schedule.

Frequently Asked Questions (FAQ)

Our cabinet is overheating, but can’t we just add more internal fans or a bigger external heatsink?

If your cabinet is sealed and the ambient temperature is high, more internal fans will only homogenize the hot air, not remove it. A larger external heatsink can help, but it’s still a passive solution that loses effectiveness as the outside temperature rises. If you need to cool below ambient, these methods are insufficient.

How does this type of system handle the peak heat load on a summer afternoon?

Modern miniature DC compressors are variable-speed. This allows them to ramp up to meet high thermal loads during the hottest part of the day and then scale back down during cooler periods or low-usage times, which is far more efficient than a simple on/off thermostat.

What is the power draw impact on our 48V DC power plant?

Power consumption depends on the heat load but typically ranges from 50 to 350 watts. This is a critical factor to include in your site’s overall power budget, but it’s often a necessary trade-off to ensure equipment reliability and network uptime.

Our cabinet is already crowded. How does a compressor system fit?

This is a primary design constraint. Miniature compressor technology is specifically designed for these space-constrained applications. However, careful planning during the cabinet design phase is key to ensure proper fit and adequate airflow for both the cooling unit and the electronics it protects.

What happens if the ambient temperature goes above 50°C?

These systems are typically designed to operate in high ambient temperatures, often up to 55°C. However, as the ambient temperature rises, the compressor has to work harder to maintain the target internal temperature, which will increase power consumption.

Is a thermoelectric (TEC) cooler a simpler alternative?

A TEC can be simpler as it’s solid-state. However, TECs are generally best for smaller heat loads and become significantly less efficient as the temperature difference (Delta T) and ambient temperature increase. For higher heat loads common in 5G equipment, a compressor-based system is often more effective and efficient.

Conclusion: Matching the Tool to the Constraints

While passive cooling and heat exchangers have their place, the operational and environmental constraints of modern telecom deployments often push them past their limits. The need for active cooling for sealed 5G cabinets becomes clear when the engineering requirements are firm: the internal temperature must be held stable, often below ambient; the enclosure must remain sealed against the elements; and the heat load is too high for less efficient technologies. When these conditions are present on your project, a direct expansion, compressor-based approach is a reliable engineering path to maintaining uptime and protecting sensitive hardware.

If your project is facing these thermal challenges, exploring the specifications of a miniature DC compressor is a logical next step in the design process.

0 条评论