Engineering for the “Zero-Touch” Deployment: Micro AC for Remote Outdoor Cabinet Applications

For OEM engineers and system integrators, the “truck roll” is the single most expensive variable in the operational expenditure (OpEx) equation. When a remote site goes offline due to thermal shutdown, the cost is rarely just the replacement hardware; it is the logistics of deploying a technician to a mountain top, a desert pipeline valve station, or an offshore platform. In these unattended environments, the cooling system is not merely an accessory; it is the primary defense against downtime.

The challenge intensifies when the deployment requires a sealed enclosure. Whether to protect against salt fog, conductive dust, or humidity, sealing the cabinet eliminates the possibility of direct air exchange (filter fans). This shifts the thermal management strategy from simple convection to active heat rejection. For many modern applications involving battery storage, edge computing, or telecom repeaters, the thermal load often exceeds what passive dissipation or thermoelectric coolers can handle efficiently.

This article analyzes the engineering constraints of cooling unattended sites and examines where a micro ac for remote outdoor cabinet integration provides the necessary thermal headroom. We will evaluate the trade-offs between power consumption, cooling capacity, and maintenance intervals to help technical buyers make defensible selection decisions.

Deployment Context: Defining the Harsh Edge

Before selecting a thermal solution, engineers must quantify the environmental hostility. “Outdoor” is too vague a specification. We typically categorize remote deployments into two high-risk scenarios where standard cooling methods often fail.

Scenario A: The High-Solar Desert Repeater

In this scenario, a telecom or radio repeater is mounted on a mast in an arid environment.

Constraints:

- Ambient Temperature: Air temperatures frequently exceed 45°C (113°F).

- Solar Loading: Direct sunlight adds a significant thermal load, often doubling the effective heat the enclosure must reject.

- Power Source: Often solar-fed with battery backup. Every watt of cooling power reduces the runtime of the primary payload.

- Dust: Fine silica dust is omnipresent. Open-loop systems (fans) clog rapidly, leading to airflow starvation and overheating.

Scenario B: The Coastal/Offshore Sensor Node

Here, a sensor array or control unit sits on a buoy or coastal infrastructure.

Constraints:

- Corrosion: Salt spray is the primary enemy. Any intake of outside air introduces corrosive elements that attack PCBs and connectors.

- Humidity: High relative humidity creates condensation risks if the internal temperature fluctuates significantly below the dew point without management.

- Maintenance Access: Access might be limited to once every 6–12 months, or require a boat/helicopter.

In both cases, the “Delta T” (the difference between internal target temperature and external ambient temperature) is often negative or near zero—meaning the outside air is as hot as, or hotter than, the desired internal temperature. This physical reality disqualifies passive cooling and simple fans.

Decision Matrix: Selecting the Right Thermal Engine

Engineers often choose between three primary technologies for sealed or semi-sealed enclosures: Filter Fans, Thermoelectric Coolers (Peltier), and Micro DC Air Conditioners (Vapor Compression). The following matrix compares these options based on critical engineering criteria.

| Criteria | Filter Fans (Open Loop) | Thermoelectric / Peltier (TEC) | Micro DC Aircon (Compressor) |

|---|---|---|---|

| Sub-Ambient Cooling | Impossible (Always T_internal > T_ambient) | Yes (Limited Capacity) | Yes (High Capacity) |

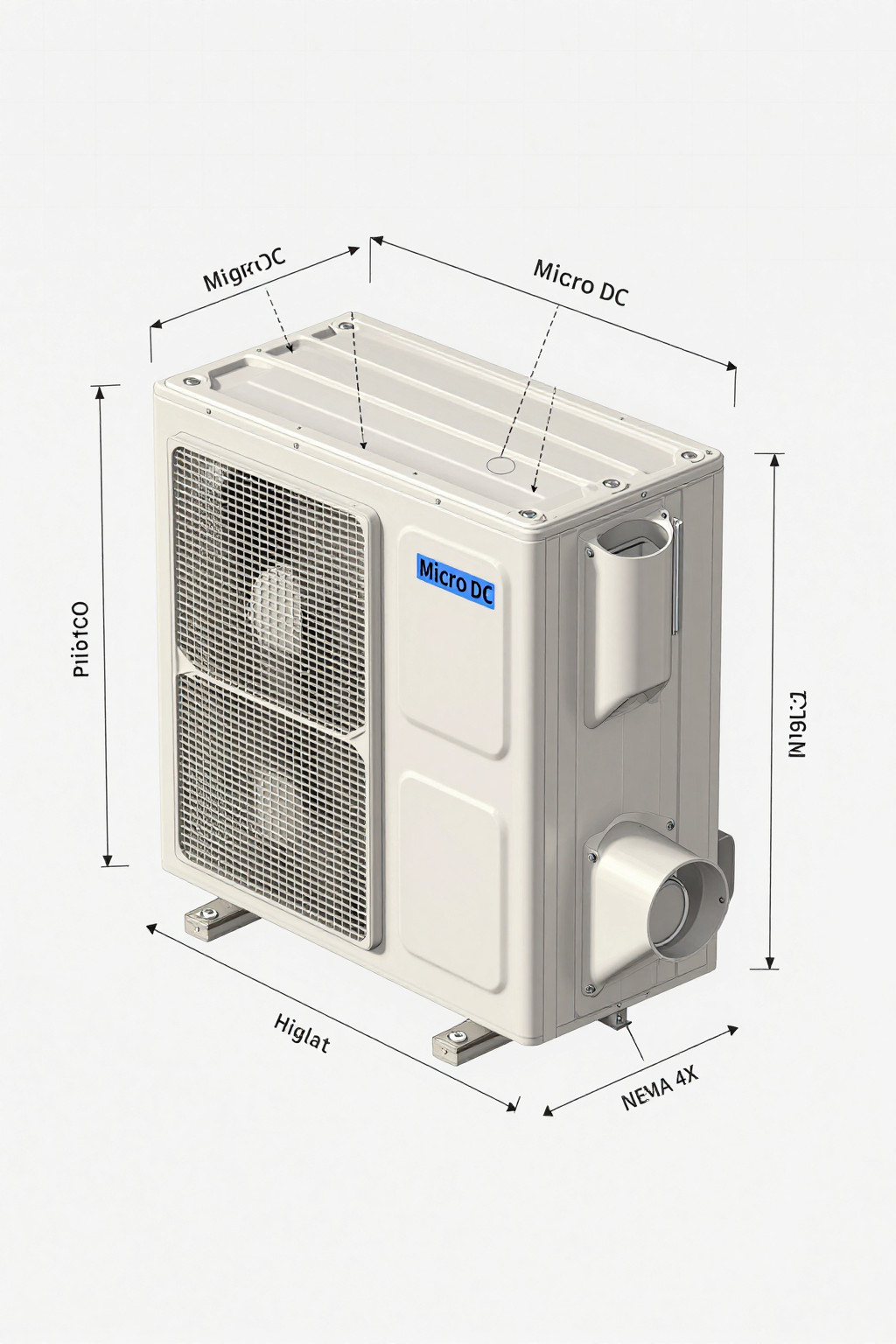

| Sealing Compatibility | Low (Requires air exchange) | High (NEMA 4X/IP65 capable) | High (NEMA 4X/IP65 capable) |

| Dust/Salt Tolerance | Poor (Filters clog; ingress risk) | Excellent (No air exchange) | Excellent (No air exchange) |

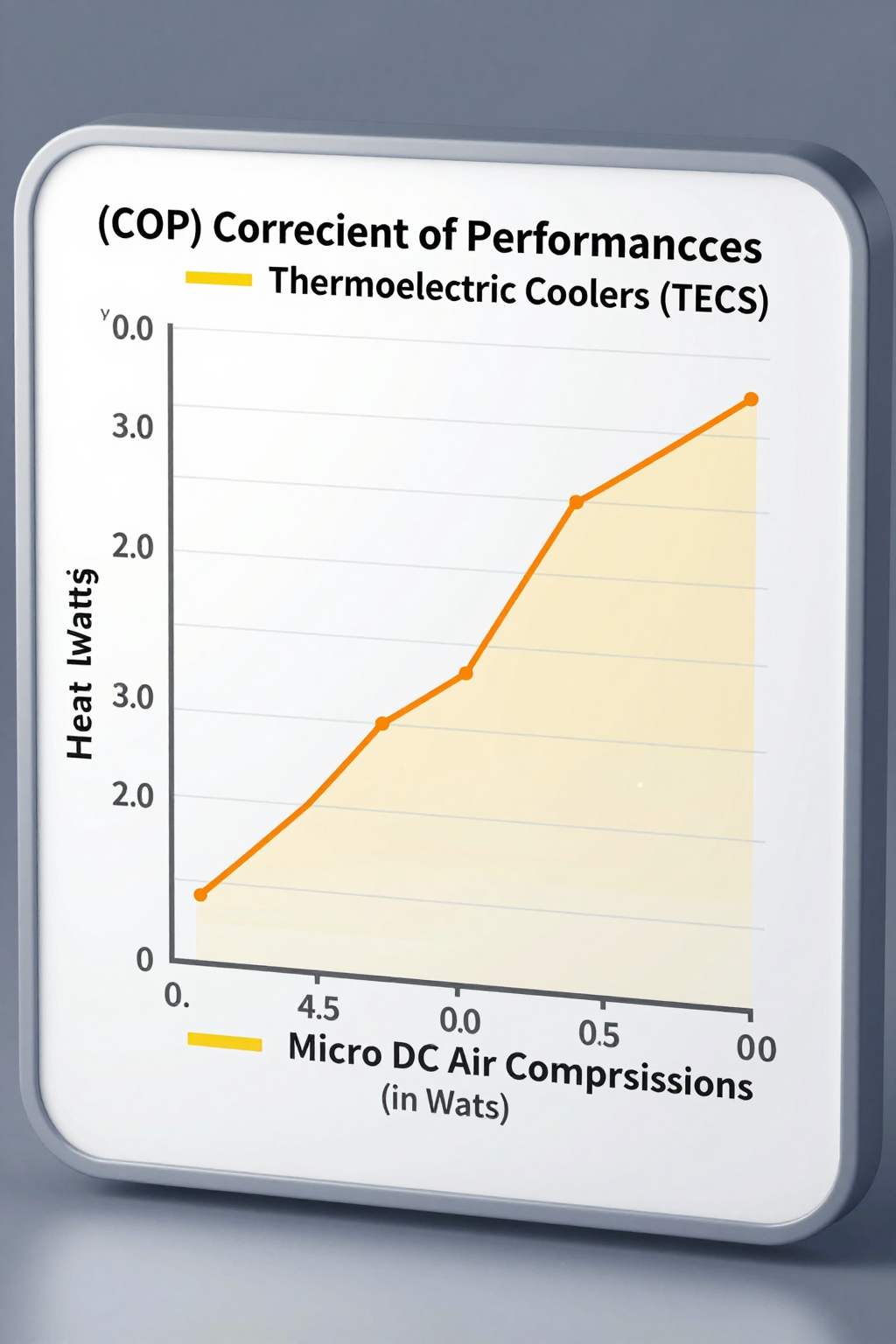

| Power Efficiency (COP) | High (but ineffective if hot outside) | Low (Typically COP < 0.6) | High (Typically COP > 2.0 – 3.0) |

| Heat Load Suitability | Low to High (Dependent on Delta T) | Low (< 200W typically) | Medium to High (100W – 900W+) |

| Maintenance Interval | Frequent (Filter changes) | Low (Solid state) | Low (No filters to change) |

Implication: If the application requires the internal temperature to be lower than the outside temperature (sub-ambient), fans are physically incapable of the task. For loads above 200W where power efficiency is critical (e.g., battery-powered sites), the Micro DC Aircon usually offers the most favorable balance of capacity per watt consumed.

Quick Selection Rules

Use these “If/Then” heuristics during your initial design review:

- Rule 1: If T_ambient > T_internal_target, you must use active cooling (TEC or Compressor). Fans cannot cool below ambient.

- Rule 2: If the enclosure must be sealed (NEMA 4/4X or IP65+) to prevent dust/salt ingress, avoid filter fans entirely.

- Rule 3: If the heat load exceeds 200W–300W and the power source is limited (batteries/solar), a compressor-based solution is typically preferred over TEC due to the Coefficient of Performance (COP) advantage.

- Rule 4: If the site is “zero-maintenance” for >1 year, avoid systems that rely on consumable media like air filters.

- Rule 5: If precise temperature control is required to protect battery chemistry, look for inverter-driven systems that can modulate speed rather than simple on/off cycling.

Unseen Enemies of Uptime: Failure Modes

Why do remote cabinets fail? Often, the root cause is not the electronics themselves, but a failure in the thermal support system. Understanding these failure modes is essential for designing resilient systems.

1. The Filter Clog (Airflow Starvation)

In open-loop systems, the filter is the single point of failure. In dusty environments, a filter can reach 80% blockage in a matter of weeks. As static pressure rises, airflow drops precipitously. The internal components eventually hit their thermal junction limits and shut down.

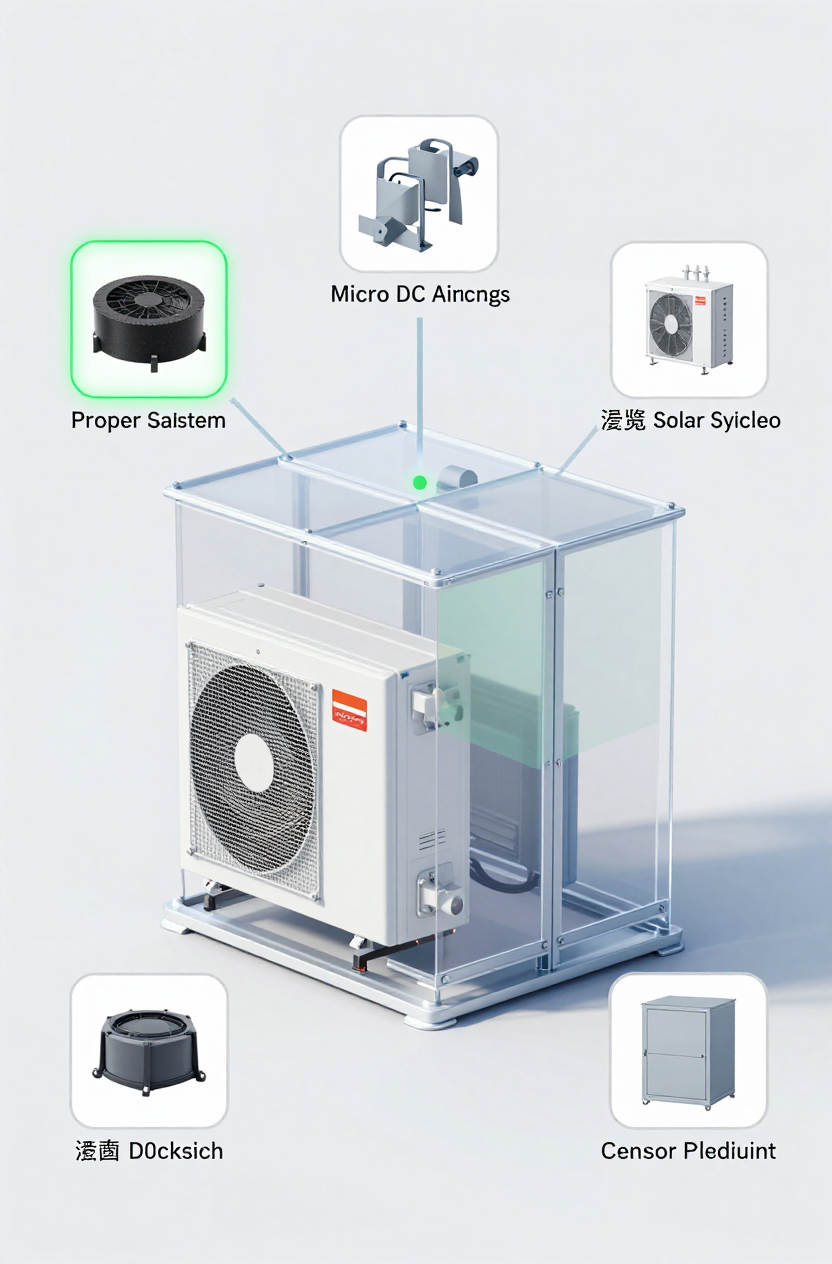

Mitigation: Switch to closed-loop cooling (Micro DC Aircon) which recirculates internal air and rejects heat via a sealed heat exchanger, eliminating the need for intake filters.

2. The “Delta T” Trap

Designers sometimes size cooling based on average ambient temperatures, ignoring peak solar loading. A cabinet might be fine at 35°C ambient, but at 45°C with direct sun, the internal temperature can spike to 65°C+ if the cooling system lacks the “headroom” to reject heat against that gradient.

Mitigation: Size the cooling capacity with a safety margin for peak solar load, not just internal dissipation.

3. Condensate Mismanagement

Active cooling removes moisture from the air. If a cooling unit chills the air below the dew point, water forms. In a poorly designed system, this water can drip onto electronics.

Mitigation: Ensure the cooling solution has an integrated condensate collection and evaporation system or a routed drain line. Proper insulation of cold surfaces is also critical.

4. Inrush Current Trips

Older AC compressors have high startup currents (Locked Rotor Amperage) that can trip breakers or cause voltage sags in DC battery systems.

Mitigation: Utilize DC inverter compressors (BLDC) which feature “soft-start” capabilities, ramping up speed gradually to avoid current spikes.

Engineering Fundamentals: The Vapor Compression Advantage

To understand why a Micro DC Aircon is often the preferred choice for harsh environments, we must look at the thermodynamics. Unlike fans that simply move air, or TECs that use the Peltier effect (which is inefficient at high heat loads), a vapor compression cycle uses a refrigerant phase change to move heat.

The compressor pressurizes a refrigerant (like R134a or R290), creating a hot gas that condenses into a liquid, rejecting heat to the outside air. This liquid then expands and evaporates in the internal evaporator coil, absorbing heat from the enclosure. This phase change allows the system to move significant amounts of thermal energy “uphill” (from a cool interior to a hot exterior) with high efficiency.

The Efficiency Gap: A typical Thermoelectric cooler might have a COP of 0.5 to 0.8 (moving 0.5 to 0.8 watts of heat for every 1 watt of electricity). A modern Micro DC Aircon using a rotary BLDC compressor often achieves a COP between 2.0 and 3.0. For a remote site running on solar, this 3x to 4x efficiency difference translates directly to smaller solar panels and smaller battery banks, significantly reducing the total cost of ownership.

Sealing Reality Clause: Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality.

Performance Data & Verified Specs

When specifying a unit, it is crucial to look at verified performance data rather than marketing claims. The following table outlines the specifications for the DV series Micro DC Aircon, a common choice for these applications due to its compact footprint and DC voltage compatibility.

| Model (Pro Series) | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC | 12V | 450W | R134a | Inverter Rotary |

| DV1920E-AC | 24V | 450W | R134a | Inverter Rotary |

| DV1930E-AC | 48V | 450W | R134a | Inverter Rotary |

| DV3220E-AC | 24V | 550W | R134a | Inverter Rotary |

Note: Capacity varies based on operating conditions (LBP/HBP). The models listed utilize BLDC inverter rotary compressors, allowing for variable speed control and soft-start functionality.

For applications requiring component-level integration, engineers might also consider the Miniature DC Compressor series (e.g., QX1902VDL or QX3202VDL) to build custom thermal loops. However, for most cabinet retrofits or standard builds, the integrated “drop-in” units (DV series) reduce engineering time.

Field Implementation Checklist

Successful deployment requires more than just buying the right part. It requires correct integration. Use this checklist before signing off on a design.

Mechanical Integration

- Gasketing: Ensure the mounting flange uses a high-quality, closed-cell foam gasket. A micro-leak here defeats the purpose of a NEMA 4X rating.

- Airflow Path: Do not block the intake or exhaust of the cooling unit. Short-cycling (where hot exhaust air is immediately sucked back into the intake) will ruin efficiency and capacity.

- Vibration: While rotary compressors are low-vibration, ensure the mounting panel is rigid enough to prevent resonance.

Electrical & Power

- Wire Sizing: DC systems are sensitive to voltage drop. Undersized cables over long runs will cause the unit to shut down on “Low Voltage Protection” even if the battery is full. Calculate voltage drop at max load.

- Protection: Install a dedicated fuse or breaker sized for the unit’s max current, not just nominal current.

Thermal Management

- Solar Shielding: Always install a sunshield (double-wall or simple shade) over the cabinet if possible. Blocking direct solar gain is the cheapest way to increase cooling performance.

- Sensor Placement: If using an external temperature sensor for control, place it at the hottest point in the cabinet (usually near the top exhaust of the equipment), not at the bottom where air is coolest.

Expert Field FAQ

Q: Can I run a Micro DC Aircon directly off a solar panel?

A: Typically, no. While the voltage might match, the current fluctuation from a panel is too unstable. These units are designed to run off a battery bank (12V/24V/48V) which acts as a buffer. The solar controller charges the battery, and the battery powers the cooler.

Q: What happens if the battery voltage drops too low?

A: Most integrated driver boards (like those in the DV series) have built-in low voltage protection. The unit will cut out to protect the battery from deep discharge and automatically restart once voltage recovers.

Q: How does a micro ac for remote outdoor cabinet handle condensation?

A: It depends on the model. Some units rely on a drain tube that must be routed out of the cabinet. Others use a condensate evaporation system or wick. In high-humidity environments, a drain tube is usually the safest, most reliable method to ensure water leaves the enclosure.

Q: Is R134a the only refrigerant option?

A: While R134a is standard for many models like the DV1910E-AC, newer iterations and specific series are moving toward R290 (Propane) or R1234yf to meet low-GWP (Global Warming Potential) regulations. Check the specific model specs for compliance requirements.

Q: Can these units heat as well as cool?

A: Standard models are usually “cool only.” However, because the enclosure is sealed, waste heat from the electronics is often enough to keep the cabinet warm in winter. If active heating is needed, a separate resistive heater is typically installed, as reverse-cycle heat pumps can be complex to manage in these small form factors.

Q: How often is maintenance required?

A: For a closed-loop compressor system, the internal loop is sealed. The external heat exchanger (condenser) may need occasional cleaning if dust buildup is extreme, but it is far more forgiving than a filter fan. In many deployments, these run for years without intervention.

Conclusion: The Logic of Resilience

The decision to deploy a Micro DC Aircon in a remote outdoor cabinet is rarely about luxury; it is about the mathematics of reliability. While the upfront cost of a compressor-based system is higher than a fan, the ROI is realized in the elimination of a single truck roll.

If your deployment faces high ambient temperatures, requires a sealed enclosure for ingress protection, and demands power efficiency to preserve battery life, vapor compression is often the only viable engineering path. By selecting a solution with the right voltage match (12V/24V/48V) and adequate thermal headroom, you transform a vulnerability into a stronghold.

Request Sizing Assistance

Proper sizing is critical to avoid short-cycling or under-cooling. To get a defensible recommendation for your specific project, please prepare the following inputs and contact our engineering team:

- Target Internal Temperature: (e.g., 25°C, 35°C)

- Max Ambient Temperature: (e.g., 50°C)

- Heat Load Estimate: (Total watts dissipated by equipment)

- Power Source: (Voltage and available current/battery capacity)

- Sealing Requirement: (IP rating or NEMA type)

- Solar Load: (Exposed surface area and orientation)

0 条评论