Angle: The decision moment is choosing between passive cooling (fans, heat exchangers) and active, closed-loop cooling for a sealed roadside cabinet. The primary failure modes are thermal shutdown from solar gain and component failure from dust/moisture ingress. The dominant constraint is maintaining the integrity of a sealed NEMA-rated enclosure in a harsh roadside environment.

Solving Traffic Signal Cabinet Overheating: A Guide to Micro DC Air Conditioner for Traffic Cabinet Integration

A single intersection gridlocked on a sweltering August afternoon is more than an inconvenience; it’s a public safety risk and a symptom of a critical infrastructure failure. The cause is often an anonymous, sun-beaten metal box on the roadside: an overheated traffic control cabinet. Inside, the processors, network switches, and power supplies that manage traffic flow have reached their thermal limits and shut down. For system integrators and OEM engineers designing Intelligent Transportation Systems (ITS), preventing this scenario is a primary design objective. The challenge is removing damaging heat while protecting sensitive electronics from the equally damaging elements of the outside world.

Simply venting the enclosure is not a viable option in most roadside deployments. This article provides a data-driven framework for making a critical design decision: when to move beyond passive cooling methods and specify an active, closed-loop system. By the end, you will understand the engineering trade-offs and be able to determine the precise conditions that require a micro dc air conditioner for traffic cabinet deployment. In this analysis, we prioritize long-term system reliability and maintaining a sealed enclosure over minimal upfront cost, exploring how active vapor-compression cooling addresses the failure points of traditional methods in high-stakes ITS deployments.

Deployment Context: Two Common Scenarios

The need for robust thermal management is not abstract. It arises from specific, challenging environmental contexts where conventional cooling methods often fall short.

Scenario A: The Urban Canyon Intersection

Consider a NEMA 3R cabinet at a busy downtown intersection. It’s surrounded by asphalt and concrete, creating a local heat island effect where ambient temperatures can soar well above official weather reports. This cabinet, housing a traffic controller, a power-over-ethernet (PoE) network switch for cameras, and a battery backup unit, was initially specified with a filtered fan system. Within a year, the filters became clogged with brake dust, road salt residue, and other urban particulates. Airflow dropped to near zero, and on a 38°C (100°F) day, the internal temperature spiked, causing the PoE switch to fail and taking the intersection’s cameras offline. The core constraint was the impossibility of maintaining clean airflow with an open-loop system in a high-particulate environment.

Scenario B: The Sun-Exposed Highway ITS Hub

Along a major highway, a fully sealed NEMA 4 cabinet contains sensitive sensor processing hardware and 5G communication modems for real-time traffic data analysis. This cabinet sits on a concrete pad with no shade, exposed to direct solar radiation from dawn until dusk. The system integrator initially chose a thermoelectric (Peltier) cooler to maintain the seal. However, the combination of a 250W internal heat load from the electronics and an intense solar gain of over 800W on the cabinet’s surface overwhelmed the cooler’s capacity. The internal processor began to thermally throttle, dropping critical data packets and compromising the integrity of the traffic monitoring system. The dominant constraint here was the massive total heat load and the high thermal delta required to keep electronics cool when the cabinet’s exterior surface temperature was over 65°C (149°F).

Common Failure Modes & Design Constraints

When designing for roadside cabinets, engineers must anticipate and mitigate a specific set of risks. These issues are often interconnected, with one failure leading to another. Understanding them is key to selecting the right thermal management strategy.

- Thermal Throttling → Cause: High internal temperatures force processors to slow down to prevent damage. → Why it matters: Leads to reduced system performance, data loss, and unreliable operation.

- Component Shutdown → Cause: Electronics exceed their maximum rated operating temperature. → Why it matters: Results in complete system failure, causing service outages (e.g., a dark intersection).

- Seal Compromise → Cause: Using filtered fans or vents to achieve cooling. → Why it matters: Allows dust, humidity, and corrosive agents to enter, leading to short circuits and premature component failure.

- Condensation Formation → Cause: Internal air temperature drops below the dew point without proper dehumidification. → Why it matters: Can cause catastrophic water damage to PCBs and power connectors.

- Solar Gain Overload → Cause: Intense, direct sunlight adds a significant heat load that passive coolers cannot reject. → Why it matters: The internal temperature can climb far above the ambient air temperature, overwhelming the cooling system.

- Power Supply Overheating → Cause: PSUs are often a major heat source and are sensitive to high temperatures. → Why it matters: A failing PSU can cause cascading failures across all connected electronics.

- Battery Degradation → Cause: High-temperature operation drastically shortens the lifespan and reduces the capacity of backup batteries. → Why it matters: Unreliable backup power during an outage defeats its purpose.

- High Maintenance Burden → Cause: Cooling systems that rely on filters require frequent cleaning or replacement. → Why it matters: Increases operational costs and requires regular site visits by technicians, which can be difficult and hazardous.

Engineering Fundamentals: Closed-Loop Cooling vs. Air Exchange

The core decision in cabinet cooling comes down to one fundamental choice: do you exchange the internal air with external air (open-loop), or do you recirculate and cool the internal air while keeping the enclosure sealed (closed-loop)? For sensitive roadside electronics, the engineering consensus strongly favors a closed-loop approach. A micro dc air conditioner for traffic cabinet is a prime example of this methodology.

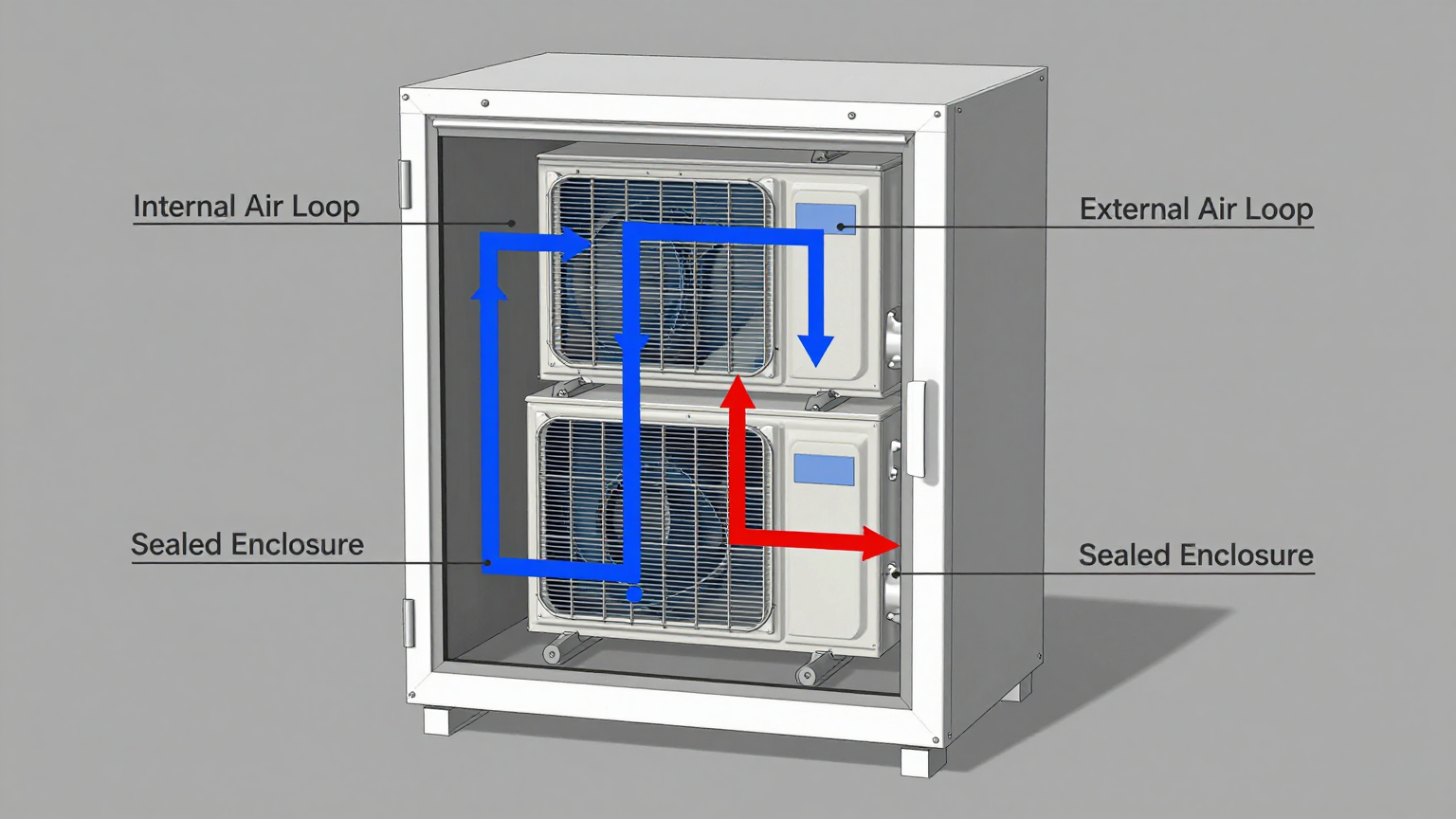

A closed-loop system operates with two completely separate air paths. The internal loop draws warm air from the top of the cabinet, passes it over a cold evaporator coil to remove heat and moisture, and then pushes the cooled, dehumidified air back into the bottom of the cabinet to flow over the electronics. The external loop draws ambient air, passes it over a hot condenser coil to expel the captured heat, and exhausts it back to the outside. At no point do the two air streams mix. This maintains the cabinet’s NEMA or IP rating, ensuring that dust, water, and corrosive gases stay out.

A common misconception is that more airflow is always the solution to an overheating problem. This leads to specifying larger fans or more vents. The correction is that the goal is not simply airflow, but targeted heat removal while preserving a clean, sealed environment. Uncontrolled airflow is a contamination vector. An active, closed-loop system like a Micro DC Aircon achieves this by using a vapor-compression cycle—the same reliable technology found in industrial and residential air conditioning, but miniaturized for compact electronic enclosures.

Key Specifications for a Micro DC Air Conditioner for Traffic Cabinet

When evaluating a sealed outdoor cabinet cooling ITS solution, the datasheet provides the critical go/no-go parameters. The decision to select a specific series or model must be grounded in these numbers. Here is a baseline for the Micro DC Aircon series, which serves as a foundation for a proper thermal audit.

| Parameter | Specification Range / Type | Significance for Cabinet Integration |

|---|---|---|

| DC Voltage Options | 12V / 24V / 48V | Must match the cabinet’s DC power bus. 48V is common in telecom and ITS for efficient power transmission. |

| Nominal Cooling Capacity | 100W – 900W | The primary performance metric. Must exceed the total heat load (internal electronics + solar gain). |

| Refrigerant | R134a / R290 / R1234yf | Indicates a true vapor-compression system. Different refrigerants are used based on efficiency and environmental regulations. |

| Technology | BLDC Inverter Rotary Compressor | Enables variable-speed operation for high efficiency and soft startups, reducing inrush current on the DC supply. |

| Control System | Integrated Driver Board (PCB) | Allows for software control, fault monitoring, and precise temperature regulation. |

| Example Models | DV1920E-AC (Pro): 24V, 450W nominal cooling, R134a DV1930E-AC (Pro): 48V, 450W nominal cooling, R134a |

|

How to read these specs: The “Nominal Cooling Capacity” is a benchmark measured under specific lab conditions (e.g., 35°C internal, 35°C ambient). In a real-world traffic cabinet application, this capacity must be derated for higher ambient temperatures. Always consult performance curves to ensure the unit can deliver the required cooling at your project’s maximum expected ambient temperature.

Engineering Selection Matrix: Logic Gates for Integration

An engineer’s selection process is a series of logic gates. If a proposed solution fails to pass a critical gate, it is not a viable option. For roadside cabinet cooling, the process often looks like this.

Logic Gate 1: Seal Integrity (NEMA/IP Rating)

- The Constraint Gate: The project specification requires the cabinet to maintain a NEMA 4/4X or IP66 rating, protecting against powerful water jets, dust, and corrosion.

- The Decision Trigger: Any solution that requires venting the enclosure to the outside atmosphere is immediately non-compliant.

- Engineering Resolution: This gate filters out all open-loop filtered fan systems. The only remaining options are fully sealed solutions: passive heat exchangers, thermoelectric coolers, or a micro dc air conditioner for traffic cabinet.

- Integration Trade-off: The upfront capital cost for a sealed system is higher than for a simple fan. However, this is offset by eliminating the long-term operational costs of filter maintenance and the much higher financial risk of contamination-related system failure.

Logic Gate 2: The Thermal Delta Requirement

- The Constraint Gate: The maximum allowable internal temperature for the electronics is T_internal, and the maximum expected ambient temperature is T_ambient. The required thermal delta is the difference between them.

- The Decision Trigger: If T_internal must be kept at or below T_ambient. For example, if sensitive components must be kept at 35°C (95°F) while the summer ambient temperature can reach 45°C (113°F).

- Engineering Resolution: This gate disqualifies passive heat exchangers. A heat exchanger can only cool the internal temperature *towards* the ambient temperature; it can never go below it. Thermoelectric coolers can create a delta, but they become highly inefficient as this delta increases. A vapor-compression system is the most effective technology for maintaining an internal temperature significantly below ambient.

- Integration Trade-off: An active micro dc cabinet air conditioner for roadside use introduces a higher power draw on the DC bus compared to a heat exchanger. This power budget must be accounted for, but it is the necessary trade-off to meet the thermal requirement.

Logic Gate 3: Total Heat Load (Internal + Solar)

- The Constraint Gate: The total heat that must be removed from the cabinet is the sum of the heat generated by all internal electronics plus the heat absorbed from solar radiation.

- The Decision Trigger: If the calculated total heat load exceeds the practical cooling capacity of alternative technologies. Thermoelectric coolers are generally most effective for loads under 200-250W in high-ambient conditions.

- Engineering Resolution: For heat loads from 250W to over 900W, a vapor-compression micro dc air conditioner for traffic cabinet becomes the more robust and efficient solution. The technology scales effectively, offering higher cooling capacity in a compact form factor.

- Integration Trade-off: Higher capacity units may have a larger physical footprint and mass, requiring careful planning for mounting location and structural support on the cabinet wall. This must be considered during the mechanical design phase.

Implementation & Verification Checklist

Proper installation is just as critical as proper selection. A high-performance cooling unit can be compromised by a poor install. Follow this checklist for a successful deployment.

-

Mechanical Integration

- Mounting Surface: Ensure the cabinet wall is flat, rigid, and strong enough to support the unit. Use all provided mounting points.

- Sealing Gasket: Clean the mounting surface thoroughly. Apply the gasket carefully to create a continuous, compressed seal with no gaps. This is critical for maintaining the NEMA/IP rating.

- Airflow Integrity: Verify that the internal cool air outlet and warm air return are not blocked by cables, components, or brackets. Likewise, ensure the external condenser intake and exhaust have several inches of clearance.

-

Electrical Integration

- Power Budget: Confirm the cabinet’s DC power supply can provide the required continuous current and handle the brief inrush current when the compressor starts.

- Circuit Protection: Install an appropriately rated fuse or circuit breaker in-line with the unit’s positive power lead as close to the source as possible.

- Wiring: Use the wire gauge specified in the installation manual to prevent voltage drop, especially over longer wire runs. Ensure all power connections are tight and secure.

-

Thermal Validation

- Sensor Placement: For system monitoring, place an independent temperature sensor near the warm air intake of the cooling unit (typically at the top of the cabinet). This represents the hottest internal air temperature and is the best metric for control. Do not place it directly in the cold air stream.

- Acceptance Test: After installation, perform a load test. Run all internal electronics at their maximum expected operational state on a hot, sunny day. Log the internal cabinet temperature over several hours to confirm it remains stable and below the specified maximum.

-

Maintenance Planning

- Condenser Coils: The external condenser coils are the only part that may require periodic maintenance. Schedule a visual inspection every 6-12 months to check for accumulated dust, leaves, or debris that could impede airflow. Clean gently with compressed air or a soft brush if needed.

- Seal Inspection: During routine cabinet maintenance, visually inspect the mounting gasket to ensure it remains intact and compressed.

Frequently Asked Questions (FAQ)

1. What is the primary advantage of a micro dc air conditioner over a thermoelectric (Peltier) cooler?

The main advantages are efficiency and capacity. Vapor-compression systems have a much higher Coefficient of Performance (COP), meaning they provide more watts of cooling for each watt of electricity consumed. This becomes especially important for total heat loads above 200W or when a large temperature difference is required, where thermoelectric coolers become significantly less effective.

2. How does a micro dc air conditioner for traffic cabinet handle condensation?

Because the internal evaporator coil operates at a low temperature, it naturally dehumidifies the sealed air inside the cabinet. The moisture that condenses on the coil is collected in a tray and is typically channeled to the hot external condenser coil, where it evaporates away. This active dehumidification is a key benefit for protecting electronics in humid environments.

3. My cabinet is in direct sunlight. How does that affect sizing?

Direct solar radiation (solar gain) is a major external heat load that must be included in your total thermal calculation. You need to calculate the surface area of the cabinet exposed to the sun and use a standard formula (considering paint color and location) to estimate the heat load in watts. This value is then added to the internal heat load from your electronics to determine the required cooling capacity.

4. What are the essential measurements I need before I can select a cooling unit?

You need four key pieces of data: 1) The total internal heat load from all electronics in watts. 2) The maximum expected ambient air temperature at the installation site. 3) The maximum allowable internal air temperature to keep all components operating safely. 4) The available DC voltage (e.g., 12V, 24V, or 48V) and the total power available on that bus.

5. How can I validate the cooling performance after installation?

The most reliable method is data logging. Place one or more independent temperature sensors inside the cabinet (one near the top, one near the bottom) and one outside to measure ambient temperature. Log this data over a 24-hour period during the hottest time of the year. The data will clearly show if the internal temperature is being maintained within your specified limits, even during peak solar load and ambient heat.

6. What about operation in dusty, coastal, or corrosive environments?

This is where a closed-loop system excels. Because the micro dc air conditioner for traffic cabinet maintains a complete seal, it provides the best possible protection for the internal electronics from airborne dust, salt spray, and industrial pollutants. The external components of the cooling unit itself are designed for outdoor exposure, but for extremely corrosive environments, special coatings or materials may be available depending on the model.

Conclusion: The Right Tool for a Demanding Job

The decision to integrate a micro dc air conditioner for traffic cabinet is an engineering choice driven by constraints. It is the best-fit solution when maintaining a sealed NEMA or IP-rated enclosure is non-negotiable, when the required internal temperature is close to or below peak ambient temperatures, and when the total heat load from electronics and solar gain exceeds the practical limits of passive or thermoelectric systems. For low-power applications in mild climates with no seal requirement, it may be over-specified. But for critical ITS and roadside infrastructure, where reliability is paramount, active closed-loop cooling provides a robust defense against the dual threats of thermal shutdown and environmental contamination.

Sizing a cooling system for a critical roadside cabinet involves more than just a datasheet. For a detailed thermal audit of your enclosure and to discuss custom configurations for your specific power, mounting, or environmental constraints, contact the Rigid Chill engineering team to ensure your infrastructure remains operational, no matter how high the temperature climbs.

0 条评论