Diagnosing the “Ghost” in the Machine: Thermal Instability in Automation

For OEM engineers and system integrators, few field failures are as frustrating as the “random” reboot. The PLC runs flawlessly for weeks, then resets intermittently between 2:00 PM and 4:00 PM. Logs show no software exceptions. Power quality analyzers show no voltage sags. The culprit is often invisible: heat. Specifically, localized thermal pockets within a sealed enclosure that push components beyond their rated operating junctions.

In harsh industrial or outdoor environments, the standard approach of “sealing the box and adding a fan” often creates a paradox. You seal the enclosure to keep out dust, moisture, and conductive contaminants (NEMA 4/4X or IP65 targets), but in doing so, you trap heat. When the ambient temperature rises—or when solar loading strikes—the internal temperature can skyrocket, leading to thermal throttling or immediate shutdown. Integrating a micro ac for PLC cabinet cooling is often the only defensible engineering strategy to maintain a sealed environment while actively rejecting heat against a high-temperature gradient.

This article explores the thermal dynamics of sealed enclosures, the limitations of passive cooling, and the engineering logic behind selecting active DC-based vapor compression systems for critical automation assets.

Deployment Context: Where Passive Cooling Fails

To understand where active cooling becomes necessary, we must look at the specific constraints of harsh deployment scenarios. In many deployments, the ambient air is not a heat sink; it is a heat source.

Scenario A: The Remote Solar-Powered SCADA Station

Consider a remote telemetry cabinet in a desert environment. The enclosure houses a PLC, a cellular modem, and a battery management system.

Constraints:

- Ambient Temperature: Often reaches 45°C to 50°C (113°F–122°F) in the shade.

- Solar Loading: Direct sunlight adds significant thermal load, effectively raising the “equivalent” ambient temperature the enclosure skin experiences.

- Power Source: 24V or 48V DC from a solar/battery bank. Inverters for AC cooling are inefficient and introduce failure points.

- Sealing: Must be NEMA 4X to prevent sand ingress and salt corrosion (if coastal).

In this scenario, a filter fan is useless because the outside air is hotter than the target internal temperature (typically 35°C for component longevity). A heat exchanger is also limited because it relies on a temperature differential that does not exist. The system requires sub-ambient cooling capability.

Scenario B: The CNC Machine Shop Floor

A compact control cabinet mounted directly on a machining center.

Constraints:

- Contaminants: Air is filled with atomized oil mist and metal fines.

- Space: Extremely limited footprint; no room for large wall-mount AC units.

- Vibration: Constant low-frequency vibration from the machining process.

Here, bringing in outside air is not an option due to the oil mist, which would coat PCBs and cause short circuits. The enclosure must be air-tight. However, the internal heat density from servo drives and the PLC is high. A micro ac for PLC cabinet applications fits this niche by providing closed-loop cooling in a form factor small enough to mount directly on the machine door.

Decision Matrix: Selecting the Right Thermal Strategy

Engineers often face a choice between simple fans, Thermoelectric Coolers (TEC/Peltier), and Vapor Compression (Compressor-based) systems. The following matrix compares these technologies based on the constraints of harsh, sealed environments.

| Criteria | Filter Fans (Open Loop) | Thermoelectric (TEC/Peltier) | Micro DC Aircon (Vapor Compression) |

|---|---|---|---|

| Sealing Compatibility | Low (Requires air exchange) | High (Closed loop) | High (Closed loop) |

| Sub-Ambient Cooling | Impossible | Yes (Limited capacity) | Yes (High capacity) |

| Cooling Capacity Range | Dependent on airflow/Delta T | Typically < 100W effective | Typically 100W – 900W+ |

| Energy Efficiency (COP) | N/A (Passive) | Low (0.4 – 0.7 typically) | High (2.0 – 3.0+ typically) |

| Power Source | AC or DC | DC | DC (Native 12/24/48V) |

| Best-Fit Scenario | Clean air, T_internal > T_ambient | Small enclosures, very low heat load | High heat load, high ambient, solar/battery power |

Implication: If your enclosure must be sealed and the ambient temperature approaches or exceeds your target internal temperature, fans are disqualified. If the heat load exceeds roughly 100W–150W, TECs often consume too much power for the cooling they provide. Vapor compression remains the standard for efficient heat rejection in the 300W–1000W range.

Quick Selection Rules

Apply these logic gates during your design review:

- Rule 1: If the ambient air temperature is higher than the maximum allowable internal temperature, you must use active cooling (Air Conditioner or Chiller).

- Rule 2: If the environment contains conductive dust, salt spray, or oil mist, you must use a closed-loop system (no filter fans).

- Rule 3: If the power source is a battery bank (12V/24V/48V), avoid AC inverters. Select native DC thermal management to reduce conversion losses.

- Rule 4: If the heat load is >150W and power is limited, vapor compression is typically 3–4x more efficient than Peltier technology.

- Rule 5: Always size for the “worst-case” scenario (max ambient + max solar load + max component load), not the average.

Failure Modes: The Unseen Enemies of Uptime

Why do PLCs reboot? It is rarely the silicon of the CPU melting. The failure modes are often more subtle and cumulative.

1. Electrolytic Capacitor Degradation

The power supply units (PSUs) powering the PLC rely on aluminum electrolytic capacitors. The life of these components follows the Arrhenius equation, which roughly states that for every 10°C rise in operating temperature, the component life is cut in half. A cabinet running at 60°C instead of 40°C may see its PSU fail in two years rather than ten. As capacitors dry out, ripple current increases, causing voltage instability that leads to random logic resets.

2. Thermal Throttling and Sensor Drift

Modern processors protect themselves by throttling speed when they hit thermal limits. In a real-time automation context, this latency can cause synchronization errors on the bus (e.g., EtherCAT or Profinet), triggering a watchdog timer trip and a system stop. Analog sensors and I/O cards also experience thermal drift, sending erroneous data that can cause logic faults.

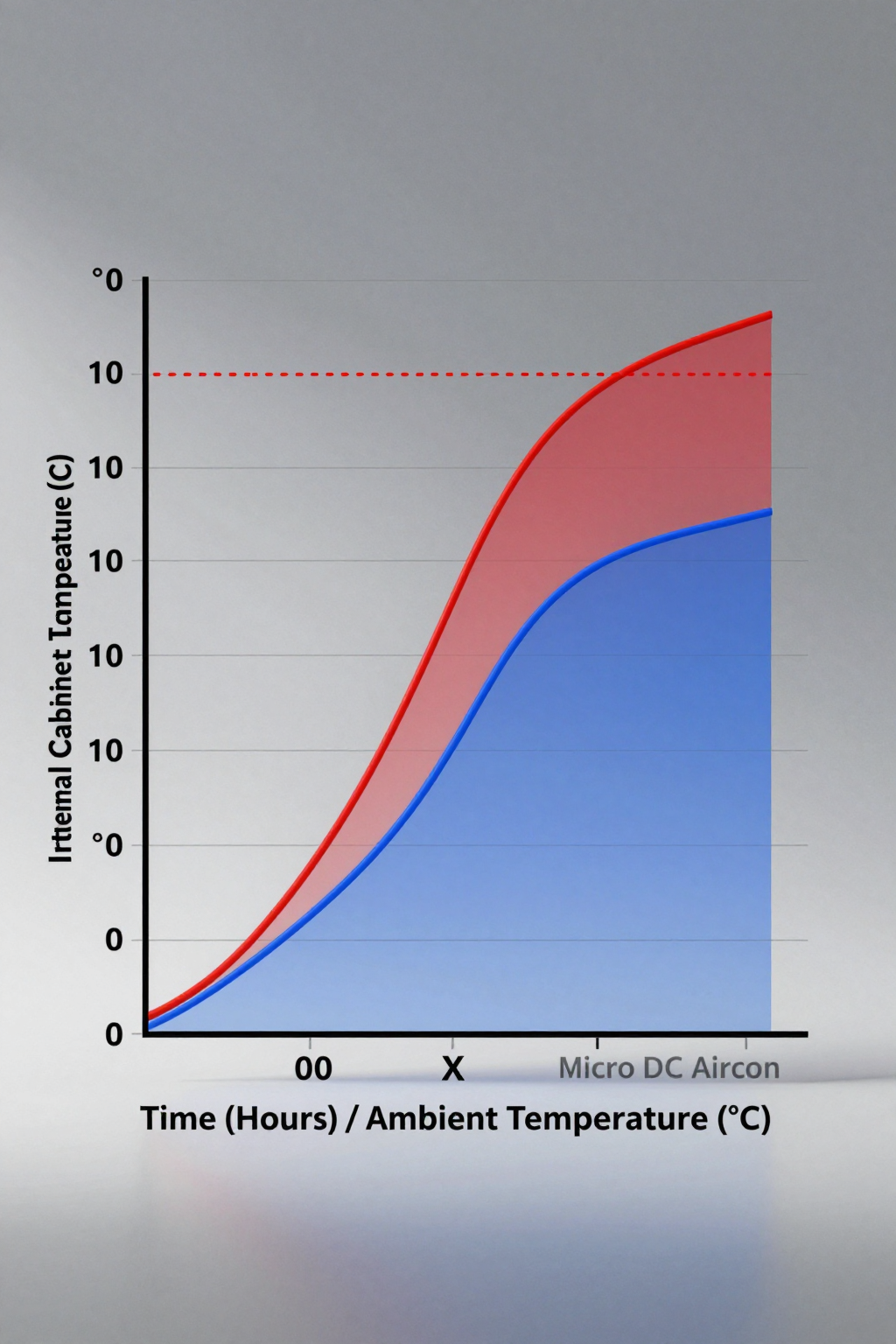

3. The “Oven Effect” in Sealed Boxes

In a NEMA 4X enclosure without active cooling, heat is transferred out only through the surface area of the cabinet. If the internal heat generation exceeds the cabinet’s ability to radiate that heat (which is low, especially for plastic or fiberglass enclosures), the internal temperature will rise until it reaches equilibrium—often well above 70°C in direct sun. This is the “oven effect” that cooks components slowly.

Engineering Fundamentals: Moving Heat “Uphill”

The core challenge in these applications is thermodynamic: moving heat from a cooler place (inside the cabinet, which you want to keep at 35°C) to a hotter place (the outside air, which might be 45°C). Heat naturally flows from hot to cold. To reverse this, work must be performed.

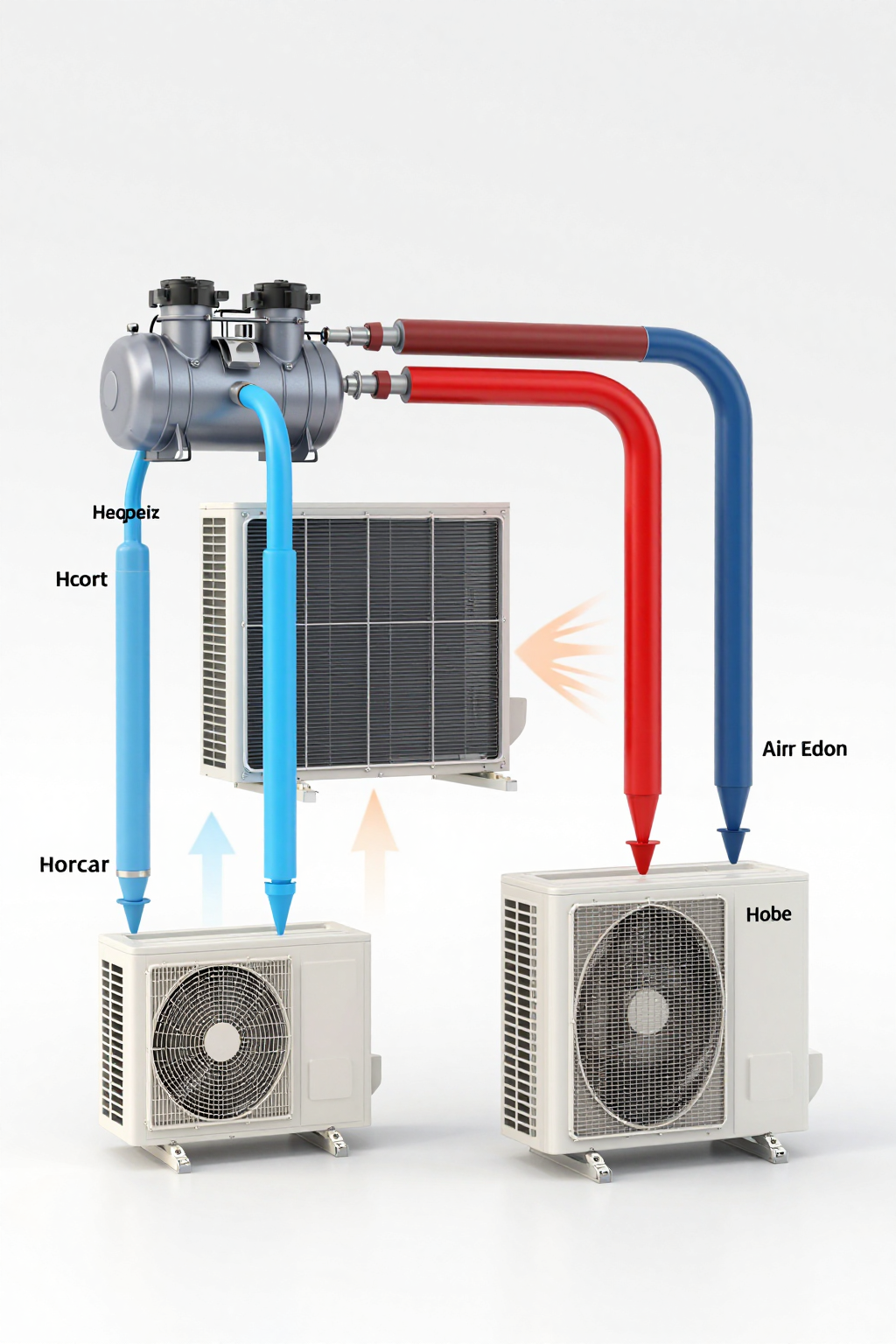

Vapor Compression Cycle: This is the same technology found in residential fridges but miniaturized. A compressor circulates a refrigerant (like R134a or R290). The refrigerant absorbs heat from the inside air at the evaporator coil (phase change from liquid to gas) and rejects it to the outside air at the condenser coil (phase change from gas to liquid).

The advantage of using a micro ac for PLC cabinet cooling lies in the phase change. The latent heat of vaporization allows a small amount of refrigerant to move a massive amount of thermal energy. This is why a compressor-based system can achieve a Coefficient of Performance (COP) of 2.5 or 3.0 (moving 3 Watts of heat for every 1 Watt of power consumed), whereas thermoelectric modules often struggle to reach a COP of 0.6.

Temperature Headroom: We often refer to the “temperature headroom” or the ability to reject heat even when the outside air is saturated with thermal energy. A compressor system maintains this headroom by compressing the refrigerant gas, raising its temperature significantly above the ambient air, ensuring heat transfer can still occur efficiently.

Performance Data: Verified Specifications

When selecting a cooling solution, verified performance data is critical. The following table highlights the capabilities of the Micro DC Aircon (Pro Series), which are designed specifically for these DC-powered, space-constrained applications.

| Model (Example) | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a | BLDC Inverter Rotary |

| DV1920E-AC (Pro) | 24V | 450W | R134a | BLDC Inverter Rotary |

| DV1930E-AC (Pro) | 48V | 450W | R134a | BLDC Inverter Rotary |

| DV3220E-AC (Pro) | 24V | 550W | R134a | BLDC Inverter Rotary |

Key Parameters to Note:

Voltage: Native 12V, 24V, and 48V options allow direct connection to the battery bus or DC power supply, eliminating the need for an inverter.

Capacity: 450W–550W is typically sufficient for a standard PLC cabinet containing a PLC, HMI, modem, and several I/O blocks.

Control: These units utilize BLDC inverter rotary compressors. Unlike “on/off” compressors, inverter-driven units can vary their speed, reducing inrush current and stabilizing the internal temperature more precisely.

Field Implementation Checklist

Successful thermal management is 20% product selection and 80% integration. Even the best micro ac for PLC cabinet applications will fail if installed poorly. Use this checklist to ensure a robust deployment.

Mechanical Integration

- Airflow Management: Ensure the “cold air out” from the AC unit is not blowing directly into the “warm air in” intake (short-cycling). Use baffles or ducting if necessary to force air through the hot components.

- Mounting Orientation: Most compressor-based units must be mounted within a specific angle of vertical (usually +/- 30 degrees) to ensure proper oil lubrication in the compressor.

- Vibration Damping: If mounting on a machine or vehicle, use rubber isolation mounts to prevent vibration from fatiguing the refrigerant lines.

Sealing and Condensate

- Condensate Drain: Active cooling removes humidity, creating water (condensate). Ensure the drain tube is routed outside the cabinet and has a trap or loop to prevent air/dust ingress.

- Gasket Integrity: Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality. A single unsealed cable gland can suck in dust and moisture, defeating the purpose of the AC.

Electrical Considerations

- Wire Sizing: DC motors draw current. Undersized wiring leads to voltage drop, which can cause the compressor driver to trip on “Under Voltage” protection. Size cables for the max current, not just the nominal.

- Circuit Protection: Always use a dedicated fuse or breaker for the cooling unit.

Expert Field FAQ

Q: Can I run a Micro DC Aircon directly off my solar battery bank?

A: Yes. This is a primary use case. Since the units accept 12V, 24V, or 48V DC directly, they integrate seamlessly with solar charge controllers. However, you must account for the energy consumption in your battery sizing calculations (autonomy days).

Q: What happens if the battery voltage drops low?

A: Most Micro DC Aircon units feature a driver board with low-voltage disconnect protection. If the battery voltage drops below a threshold (e.g., 10.5V for a 12V system), the compressor will shut off to protect the battery from deep discharge, prioritizing the PLC load.

Q: How often do I need to recharge the refrigerant?

A: In a properly manufactured hermetically sealed system, you should never need to recharge the refrigerant. It is a closed loop. If you lose refrigerant, you have a leak that must be repaired.

Q: Is a micro ac for PLC cabinet suitable for Class 1 Div 2 hazardous locations?

A: This depends on the specific model and certification. Standard units may not be spark-free. Always verify the hazardous location rating if you are in oil & gas or chemical environments.

Q: My cabinet is small. Can I just use a Peltier cooler?

A: You can, provided the heat load is very low (typically under 100W). If your heat load is 300W, a Peltier unit will likely consume 500W+ of power to cool it, which is often unsustainable for battery-powered systems. A compressor system would consume roughly 100W–150W for the same cooling effect.

Q: Does the unit run 100% of the time?

A: Ideally, no. If sized correctly, the unit should cycle or (in the case of inverter units) ramp down once the setpoint is reached. If it runs 100% of the time and never reaches the setpoint, it is undersized or the cabinet insulation is poor.

Conclusion: Defensible Design for Harsh Environments

The “random” reboot is rarely random. In sealed enclosures exposed to high ambient temperatures or solar loading, it is a predictable outcome of thermal physics. Relying on passive radiation or simple fans in these contexts is often an engineering gamble that results in high operational costs due to downtime and component replacement.

Integrating a Micro DC Aircon provides a deterministic thermal environment for your critical automation equipment. By decoupling the internal cabinet temperature from the external ambient conditions, you ensure that your PLCs, drives, and batteries operate within their validated thermal envelopes, regardless of whether the equipment is in a foundry or a desert.

For engineers building for the edge, the shift from passive to active DC cooling is not just about comfort; it is about reliability, longevity, and the elimination of the “ghost” in the machine.

Request a Thermal Sizing Consultation

Sizing a cooling solution requires more than a guess. To get a defensible recommendation for your specific application, please prepare the following inputs and reach out to our engineering team:

- Target Internal Temperature: (e.g., 35°C)

- Max Ambient Temperature: (e.g., 50°C)

- Heat Load Estimate: (Sum of Watts from all internal components)

- Enclosure Dimensions & Material: (H x W x D, Steel/Fiberglass)

- Power Source: (Voltage and available current headroom)

- Solar Loading: (Indoor vs. Outdoor/Shaded)

0 条评论