Diagnosing Thermal Trips: When to Deploy a Micro AC for VFD Cabinet Cooling

In industrial automation, summer is often the season of “phantom faults.” A Variable Frequency Drive (VFD) trips offline during the hottest part of the day, reporting an over-current or over-voltage error. A technician resets it, checks the motor, finds no issues, and restarts the line. Twenty minutes later, the system trips again. While the error code suggests an electrical anomaly, the root cause in many outdoor or unconditioned deployments is often thermal derating disguised as a hard fault.

For OEM engineers and system integrators designing for harsh environments—whether remote pump stations, mobile agricultural robotics, or roadside control panels—managing the thermal envelope is as critical as the control logic itself. When passive ventilation fails to keep internal temperatures below the drive’s derating threshold, or when ambient air is too contaminated to circulate, engineers often evaluate a micro ac for VFD cabinet integration to solve persistent tripping issues.

This article explores the engineering logic behind active cooling for small-form-factor enclosures. We will examine the thermal limits of VFDs, the physics of closed-loop cooling, and the specific deployment scenarios where a DC-powered vapor compression system becomes the defensible choice for uptime.

The Thermal Reality: Why Drives Derate and Trip

VFDs are robust, but they are governed by the physics of their power semiconductors (IGBTs). As the junction temperature of an IGBT rises, its ability to handle current diminishes. Most industrial drives are rated for full current output at 40°C or 50°C ambient. Beyond this limit, the drive’s firmware will automatically reduce the switching frequency or limit the output current to protect the silicon. If the load demand remains high while the drive is thermally throttling, the system eventually trips to prevent catastrophic failure.

In a controlled server room, this is rarely an issue. But in an outdoor cabinet exposed to solar loading, or a mobile AGV operating on hot asphalt, the internal air temperature can easily exceed 60°C if not actively managed. At these temperatures, capacitors dry out, shortening the drive’s lifespan, and nuisance tripping becomes a daily operational cost.

Deployment Context: Where Passive Cooling Fails

To understand where active cooling is required, we look at two common scenarios where standard fans or heat exchangers typically fall short.

Scenario A: The Remote Solar Pump Station

Consider a water transfer pump in a desert environment. The cabinet houses a 48V DC drive and a PLC.

Constraints:

- Ambient Temperature: Peaks at 45°C (113°F) in the shade.

- Solar Load: Direct sunlight adds significant heat load to the enclosure skin.

- Target Internal Temperature: The VFD manual specifies a max of 40°C for 100% duty cycle.

- Power Source: 48V DC battery bank charged by solar.

In this scenario, the ambient air (45°C) is hotter than the target internal temperature (40°C). A fan or air-to-air heat exchanger relies on a temperature difference to move heat. Since the outside is hotter than the inside, passive methods would actually heat the cabinet rather than cool it. Sub-ambient cooling is required.

Scenario B: The Mobile Factory Robot (AGV)

An Autonomous Guided Vehicle (AGV) operates in a metal fabrication plant.

Constraints:

- Contaminants: The air is filled with conductive metal dust and carbon fiber particles.

- Vibration: Constant movement and shock loads.

- Space: Extremely limited volume for cooling hardware.

Here, using a fan to pull in ambient air is dangerous. Conductive dust entering the cabinet can bridge circuit traces on the VFD control board, leading to short circuits. The enclosure must be sealed (NEMA 4/4X or IP65 equivalent). While the ambient temperature might be moderate, the requirement for a sealed enclosure eliminates simple fans. The heat must be rejected without air exchange.

Decision Matrix: Selecting the Right Thermal Strategy

When designing a cooling strategy, engineers must weigh the heat load against the environmental constraints. The following table compares common cooling technologies for small enclosures.

| Criteria | Filter Fans (Open Loop) | Air-to-Air Heat Exchanger | Thermoelectric (Peltier) | Micro DC Aircon (Compressor) |

|---|---|---|---|---|

| Cooling Mechanism | Ambient Air Exchange | Passive Conduction (Sealed) | Solid State Heat Pump | Vapor Compression Cycle |

| Sub-Ambient Cooling? | No (Always T_internal > T_ambient) | No (Always T_internal > T_ambient) | Yes | Yes |

| Sealed Enclosure? | No (Dust/Moisture ingress risk) | Yes | Yes | Yes |

| Power Efficiency (COP) | High (Low power draw) | High | Low (Typically COP < 0.6) | High (Typically COP > 2.0) |

| Heat Load Suitability | Low to High (Depends on airflow) | Low to Medium | Very Low (< 100W typically) | Medium to High (100W–900W+) |

| Best-Fit Scenario | Clean, cool indoor rooms | Cool, dusty environments | Low heat, vibration-sensitive | Hot, harsh, high heat load |

Implication: If your application requires the internal temperature to be lower than the outside temperature (sub-ambient), or if the heat load exceeds the low capacity of Peltier coolers, a compressor-based solution like a Micro DC Aircon is often the only viable path for a sealed enclosure.

Quick Selection Rules for Design Reviews

Use these logic gates to determine if a compressor-based micro AC is appropriate for your VFD cabinet:

- Rule 1: If Ambient Temperature ≥ Target Internal Temperature, you must use active cooling (Compressor or Peltier). Fans will not work.

- Rule 2: If the environment contains conductive dust, salts, or hose-down requirements, you must use a closed-loop system (Sealed).

- Rule 3: If the heat load is > 150W and you need active cooling, a Micro DC Aircon is typically more energy-efficient than a Peltier/Thermoelectric cooler.

- Rule 4: If power is limited (battery/solar), check the Coefficient of Performance (COP). Compressors typically move 2-3 Watts of heat for every 1 Watt of power consumed.

- Rule 5: If the cabinet is mobile (AGV/Truck), ensure the cooling unit is rated for vibration (e.g., rotary compressors).

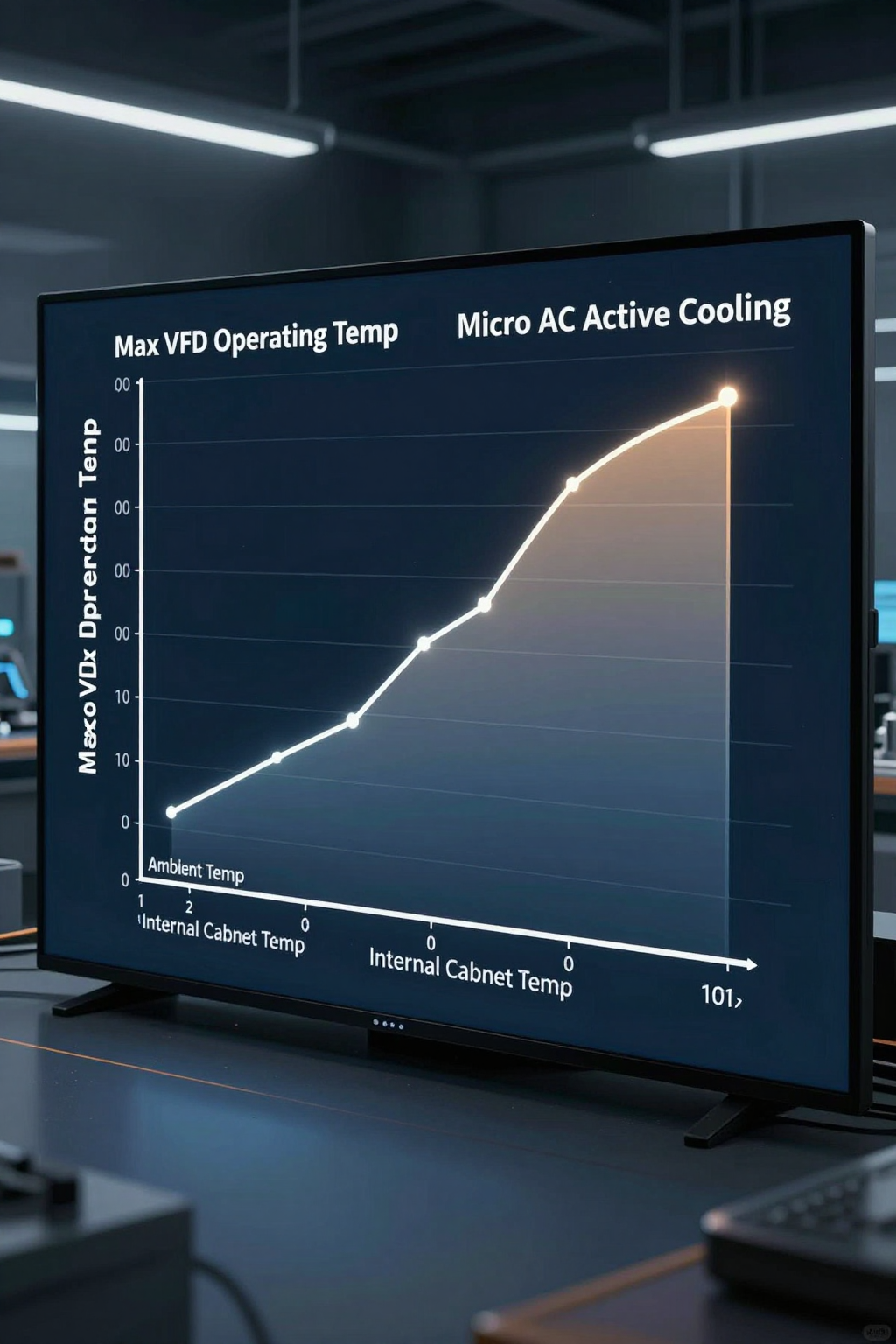

Why a Micro AC for VFD Cabinet is Often Necessary in High Ambient Heat

To understand why fans fail in high heat, we must look at the concept of “temperature headroom” (often referred to as Delta T). Heat transfer is driven by the difference in temperature. A fan cools a cabinet by replacing warm internal air with cooler external air. The rate of cooling is directly proportional to this temperature difference.

If your VFD generates 300W of waste heat and the outside air is 30°C, a fan might be able to keep the inside at 40°C. However, if the outside air rises to 40°C, the fan has zero temperature headroom. It is blowing 40°C air onto a component that wants to be 40°C. No heat transfer occurs, and the internal temperature climbs rapidly until the drive trips.

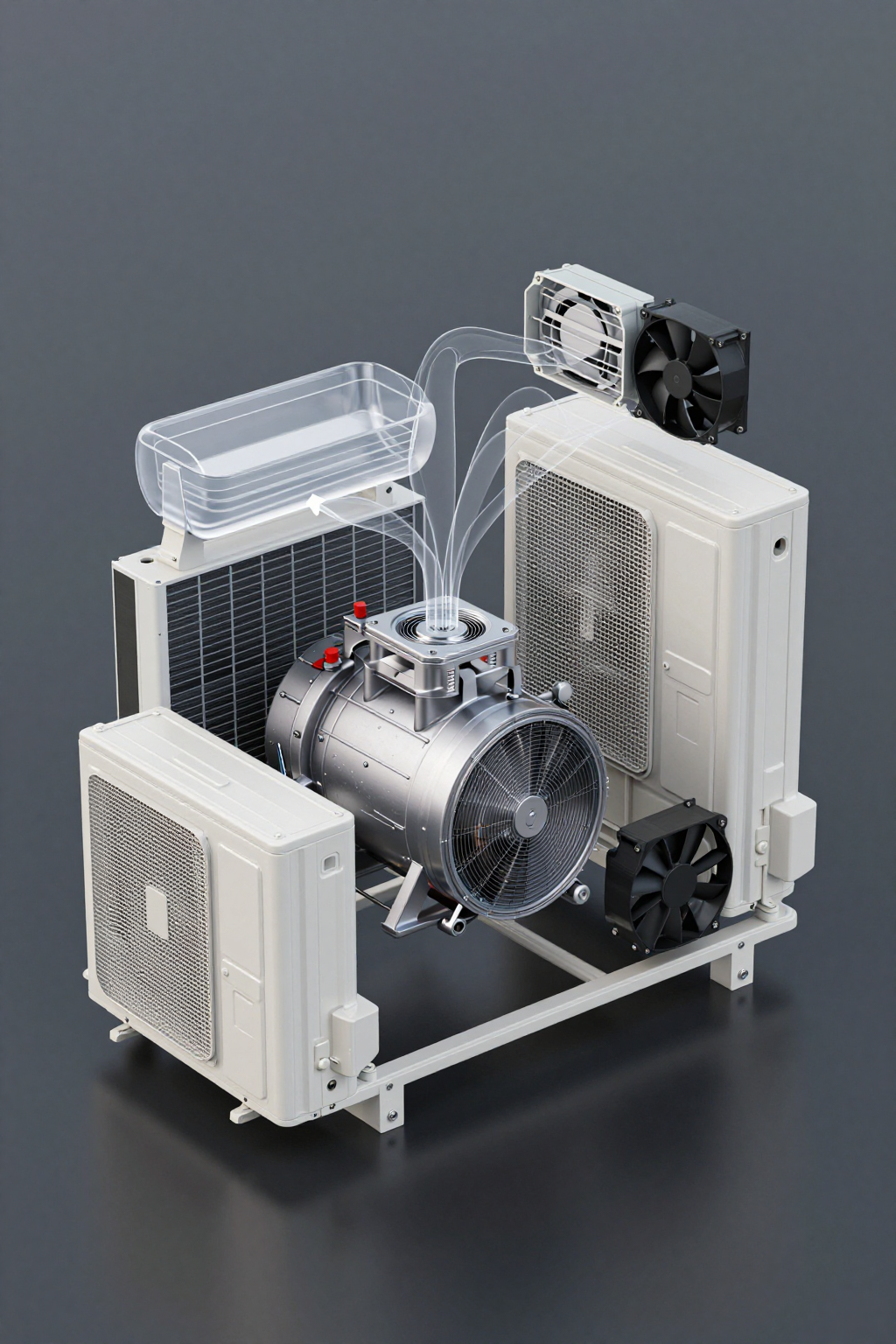

A Micro DC Aircon operates differently. It uses a vapor-compression cycle to actively pump heat out of the cabinet. By compressing a refrigerant (like R134a), it creates a cold evaporator coil inside the cabinet that is significantly colder than the target air temperature (often 10-15°C). This large temperature difference allows the system to absorb heat rapidly, even when the outside air is scorching hot. This ability to create its own “cold source” is why compressor-based cooling is the standard for harsh environments.

Failure Modes: The Unseen Enemies of Uptime

Beyond simple overheating, improper cooling leads to a cascade of failure modes in VFD cabinets. Understanding these mechanisms helps justify the investment in active cooling.

- Filter Clogging & Airflow Starvation: In open-loop fan systems, filters are the first line of defense. In dusty environments (cement, flour, mining), these filters clog within days. As airflow drops, the cooling capacity plummets. The VFD fan speeds up to compensate, drawing more current and pulling more dust into the filter, creating a feedback loop that ends in a thermal trip.

- Humidity & Condensation: In humid climates, daily temperature cycles can cause condensation to form on internal components. If a cabinet “breathes” (open loop), it pulls in moisture. A closed-loop AC system dehumidifies the internal air, collecting moisture on the evaporator coil and draining it away, keeping the electronics dry.

- Corrosion: In coastal or wastewater applications, hydrogen sulfide or salt spray can corrode copper traces and connector pins. A sealed enclosure with an internal recirculating AC prevents these corrosive agents from ever touching the drive.

- Inrush Current Stress: Some cooling solutions have high startup currents that can trip sensitive DC power supplies. Modern variable-speed DC compressors use soft-start inverters to ramp up slowly, avoiding spikes on the power bus.

Sealing Reality Clause: Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality.

Performance Data: What to Expect from Micro DC Cooling

When specifying a solution, it is critical to look at verified performance data rather than marketing claims. The Arctic-tek Micro DC Aircon series (DV models) provides a reference point for what is achievable in a compact footprint.

The following specifications apply to the DV series (e.g., DV1910E-AC, DV1920E-AC, DV1930E-AC), which utilize miniature BLDC inverter rotary compressors.

| Parameter | Specification (Example: DV19xx Series) |

|---|---|

| Nominal Cooling Capacity | 450W (varies by model/conditions) |

| Voltage Options | 12V / 24V / 48V DC |

| Refrigerant | R134a (Standard) |

| Compressor Type | Miniature Rotary BLDC Inverter |

| Control | Integrated Driver Board (Variable Speed) |

| Typical Dimensions | Compact (Suitable for small cabinets) |

These units are designed to fit where traditional AC-powered cabinet coolers cannot. The use of 12V, 24V, or 48V DC power allows them to run directly from the battery bank in mobile or off-grid applications, eliminating the efficiency loss of an inverter.

Field Implementation Checklist

Integrating a micro AC into a VFD cabinet requires attention to detail. A poor installation can negate the benefits of the hardware. Follow this checklist to ensure long-term performance.

Mechanical Integration

- Gasket Integrity: Ensure the mounting surface is flat and the provided gasket is compressed evenly. A gap of even 1mm can allow dust ingress or cool air leakage.

- Airflow Management: Do not mount the AC unit such that the cold air discharge blows directly into the VFD’s intake fan if the velocity is mismatched. Ideally, create a circulation path where cold air fills the bottom or side of the cabinet and the VFD pulls from that reservoir.

- Condensate Drainage: Active cooling removes moisture. Ensure the drain hose is routed downwards and out of the cabinet through a sealed grommet. Do not let the drain line kink.

Electrical & Power

- Wire Sizing: DC compressors draw current. Undersized wiring leads to voltage drop, which can cause the compressor driver to trigger a low-voltage cutoff. Use the recommended gauge for the run length.

- Circuit Protection: Always fuse the cooling unit separately from the VFD control logic. If the AC unit has a fault, it should not take down the PLC or Drive.

Thermal Strategy

- Solar Shielding: If the cabinet is in direct sun, install a sun shield (a simple metal plate offset by 20mm). This can reduce the solar heat load by 50% or more, allowing the micro AC to focus on the VFD heat load rather than the sun.

- Set Point Discipline: Do not set the thermostat to 20°C if 35°C is sufficient. Lower set points increase power consumption and the risk of external sweating.

Expert Field FAQ

Q: Can I power the micro AC directly from the VFD’s DC bus?

A: It depends. While some engineers tap into the DC bus, the voltage levels on a VFD bus (often 300V-600V DC) are typically much higher than the 12V/24V/48V input of these micro units. You would typically need a separate DC-DC converter or a dedicated 24V/48V power supply. Always check the voltage range of the specific model (e.g., DV1930E-AC is 48V).

Q: How do I determine the cooling capacity for a micro ac for VFD cabinet?

A: You need to sum the heat dissipation of all internal components (VFDs, PLCs, power supplies) and add the heat transfer through the cabinet walls (solar load + ambient delta). If your VFD is 95% efficient and handles 10kW, it dissipates roughly 500W of heat. A 450W unit might be undersized if there is also significant solar loading. Accurate sizing is critical.

Q: Will the vibration from the compressor affect my sensitive electronics?

A: Miniature rotary compressors, like the QX series used in these units, are inherently balanced and produce significantly less vibration than traditional reciprocating compressors. However, using rubber isolation mounts is a common practice to further decouple the cooling unit from the chassis.

Q: What happens if the condensate drain clogs?

A: If the drain clogs, water can back up into the drip tray and eventually overflow inside the cabinet. Regular maintenance checks should include verifying the drain line is clear. Some advanced integrations use a moisture sensor in the tray to trigger an alarm before overflow occurs.

Q: Is R134a the only refrigerant option?

A: While R134a is standard for many models like the DV1920E-AC, other refrigerants like R290 and R1234yf are available in certain series. R290 offers excellent thermodynamic properties but requires careful handling due to flammability.

Q: Can these units handle washdown environments?

A: The external side of the unit must meet the IP/NEMA rating of the cabinet. Many micro DC air conditioners are designed with IP55 or similar ratings for the external loop, but you should verify the specific rating in the verified_specs for your deployment environment.

Conclusion: System Logic for Resilient Design

The decision to move from passive fans to active compression cooling is rarely about luxury; it is about physics. When ambient temperatures rise above component limits, or when contaminants threaten the integrity of open-loop systems, a micro ac for VFD cabinet integration becomes a functional necessity.

By selecting a closed-loop, DC-powered solution, engineers can decouple the internal cabinet environment from the harsh reality outside. This ensures that VFDs operate within their thermal comfort zone, preventing derating, extending component life, and eliminating the “phantom faults” that plague summer operations. Whether for a Micro DC Aircon application in a remote desert or a compact chiller for a laser drive, the goal remains the same: predictable, consistent thermal performance regardless of external chaos.

Request a Sizing Consultation

Sizing a thermal management system requires more than a guess. To ensure your VFD cabinet is protected, our engineering team can assist with a detailed heat load calculation. When requesting support, please provide the following inputs:

- Heat Load Estimate: Total watts dissipated by internal components (VFDs, PLCs, etc.).

- Ambient Conditions: Maximum expected ambient temperature and presence of solar loading.

- Target Temperature: Desired internal cabinet temperature (e.g., 35°C).

- Power Availability: Voltage (12V, 24V, 48V) and current limits.

- Sealing Requirements: NEMA/IP rating targets (e.g., NEMA 4, IP65).

- Physical Constraints: Available mounting dimensions and orientation.

0 条评论