Angle: The critical decision is choosing between a simple ventilation fan and a closed-loop active cooling system for a sealed outdoor enclosure. The primary failure modes are thermal derating of electronics from solar load and premature component failure from dust and moisture ingress. The dominant constraint is maintaining a NEMA or IP rating, which makes traditional ventilation impossible.

Solving Overheating with a Micro DC Air Conditioner Outdoor Cabinet

An outdoor electrical cabinet failing in the field is more than an inconvenience; it’s a critical infrastructure failure. For system integrators deploying telecom equipment, battery energy storage systems (BESS), or remote monitoring controls, a single thermal shutdown can cause network outages, data loss, and costly emergency service calls. The core problem is often a fundamental mismatch between the cooling method and the operating environment. Simple fans, while inexpensive, introduce a fatal flaw in sealed enclosures: they require an exchange with ambient air, bringing in dust, humidity, and corrosive contaminants that the enclosure was designed to keep out. This forces a difficult trade-off between thermal management and environmental protection.

By the end of this technical guide, you will be able to determine the precise threshold where passive or fan-based cooling is no longer viable and a closed-loop system becomes a necessity. We will provide a structured engineering framework to justify the shift to an active cooling solution. In this article, we prioritize long-term component reliability and predictable performance over minimal upfront cost, because field failures consistently prove that the lowest-cost solution is rarely the most economical one. A properly specified micro dc air conditioner outdoor cabinet is not just a component; it’s an insurance policy against environmental variables.

Deployment Context: Where Standard Cooling Fails

The limitations of conventional cooling methods become apparent in specific, high-stakes scenarios where environmental factors are non-negotiable.

Scenario A: Roadside 5G Telecom Cabinet

A telecom provider deployed a series of sealed cabinets containing 5G radio equipment and power systems along a highway. The initial design used high-flow fans with filtered vents, assuming this would be sufficient. Within the first summer, multiple sites experienced intermittent network drops. Technicians found that fine dust and brake-pad particulates had clogged the filters, drastically reducing airflow. On hot, sunny days, the internal temperature exceeded the 60°C operating limit of the power amplifiers, causing them to derate and eventually shut down. The need to maintain a sealed NEMA 4 rating against road spray and dust made the ventilated design fundamentally flawed from the start.

Scenario B: Solar-Powered Kiosk in a Coastal Area

A municipality installed interactive public information kiosks powered by a small solar array and battery bank, all housed within a single sealed enclosure. The design relied on passive heat dissipation. However, the combination of direct solar radiation on the dark-colored cabinet and the heat generated by the battery charge controller and display inverter created an internal heat load far greater than anticipated. The internal temperature regularly surpassed 55°C, accelerating battery degradation and shortening its service life by an estimated 40%. The coastal location also meant that any ventilation would introduce corrosive salt fog, making a panel mount micro dc air conditioner outdoor solution the only viable path to protect the sensitive electronics and preserve the battery investment.

Failure Modes & Constraints in Sealed Enclosures

When designing for outdoor environments, engineers must anticipate a specific set of failure modes driven by thermal and environmental stress. Here are the most common issues, ranked by impact:

- Component Derating → High Internal Ambient Temperature → Reduced performance and processing power as CPUs and power supplies automatically throttle to prevent damage.

- Premature Component Failure → Sustained High Temperatures → The lifespan of capacitors, processors, and batteries is halved for every 10°C increase above their nominal operating temperature.

- Condensation & Corrosion → Ingress of Humid Air → Using fans in humid environments pulls moisture into the cabinet, which then condenses on cooler surfaces, leading to short circuits and corrosion.

- Filter Clogging & Maintenance Burden → Ventilated Design in Dusty Areas → Filters require regular, costly maintenance, and once clogged, they lead to rapid thermal runaway.

- Loss of IP/NEMA Rating → Adding Vents for Fans → Cutting holes for ventilation compromises the enclosure’s primary purpose of protecting against water, dust, and contaminants.

- Battery Damage → Overheating from Solar Load & Charging Cycles → Elevated temperatures irreversibly damage battery chemistry, reducing capacity, lifespan, and safety.

- Warranty Invalidation → Operating Electronics Outside Spec → Component manufacturers will not honor warranties if logs show the equipment was consistently operated above its maximum rated temperature.

- Unpredictable System Behavior → Cascading Thermal Failures → One overheating component radiates heat to its neighbors, creating a domino effect that can be difficult to diagnose remotely.

Engineering Fundamentals: Closed-Loop Cooling vs. Ventilation

The core decision in cabinet cooling hinges on one concept: the heat path. A ventilated cabinet uses an open-loop system. It pulls in cooler (but often dirty and humid) ambient air, passes it over the electronics, and exhausts the hot air. This only works if the outside air is significantly cooler than the target internal temperature and clean enough not to damage the components. This approach fails spectacularly when faced with the challenge of sealed enclosure cooling outdoor kiosk deployments.

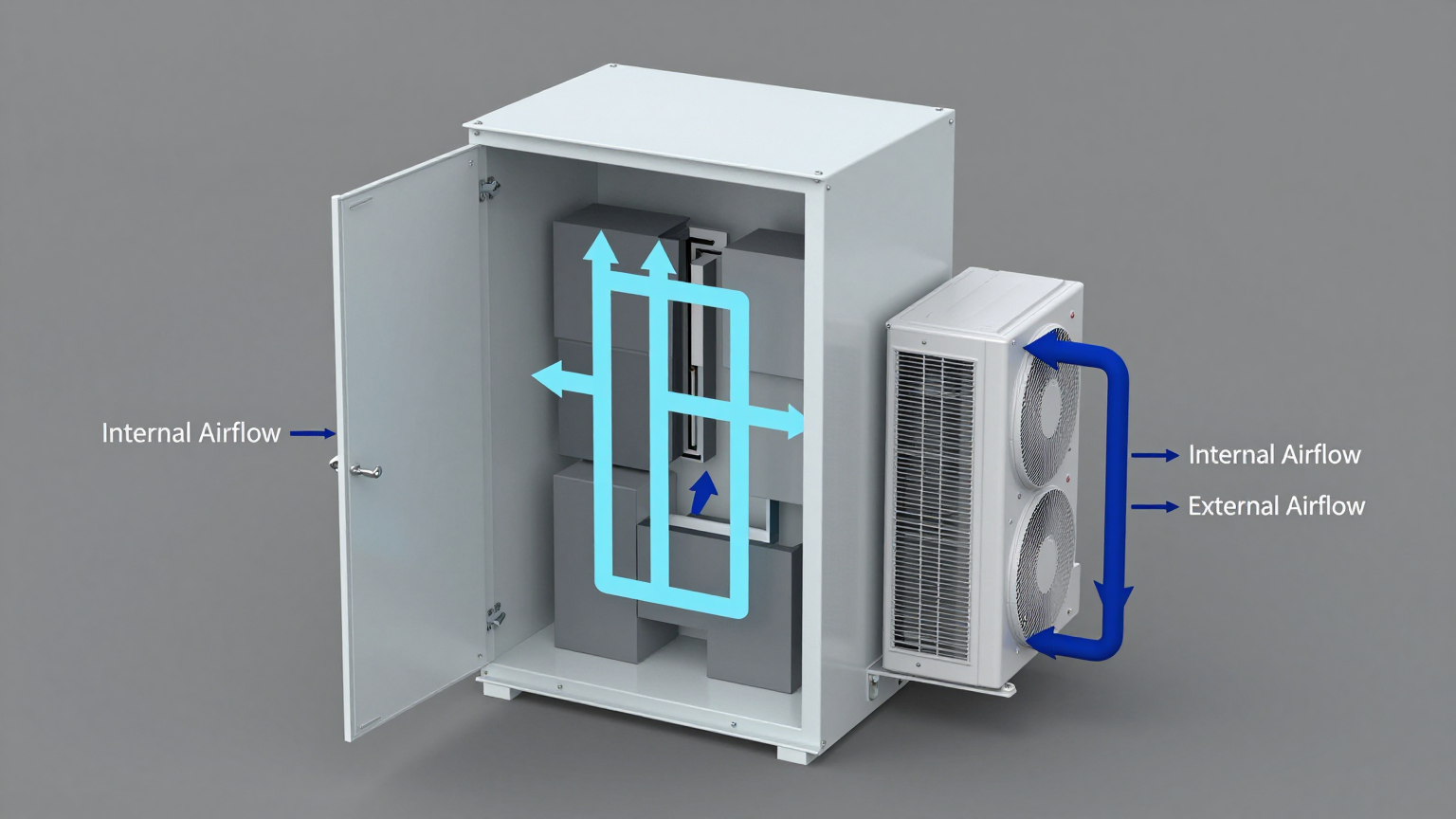

A micro dc air conditioner outdoor cabinet, by contrast, operates on a closed-loop principle. It creates two completely separate air circuits. The internal circuit continuously circulates and cools the air inside the cabinet, removing heat from the electronics. The external circuit pulls in ambient air to cool the condenser coils of the air conditioner itself and then exhausts this hot, humid air back to the environment. Crucially, the two air streams never mix. This allows the cabinet to remain perfectly sealed, preserving its IP/NEMA rating while actively pumping heat out of the enclosure. This is the only way to maintain an internal temperature at or below the external ambient temperature.

Misconception & Correction: A common mistake is to only calculate the heat generated by the internal electronics (the internal heat load). Engineers often neglect the significant impact of solar load. A dark-colored cabinet sitting in direct sunlight can absorb an additional 1,000 watts of thermal energy per square meter. This external, radiant heat load often exceeds the internal load and is the primary reason that passive and fan-cooled systems that seemed adequate on paper fail in the field. A proper thermal calculation must sum both the internal electronic heat load and the external solar load to determine the total cooling capacity required.

Key Specifications for a Micro DC Air Conditioner

When selecting a micro dc air conditioner outdoor cabinet, certain specifications are non-negotiable go/no-go gates. The table below outlines typical parameters for our Micro DC Aircon series. The key is to match the unit’s cooling capacity to your total heat load (internal electronics + solar gain) at the maximum expected ambient temperature, while ensuring the voltage matches your power system.

| Parameter | Specification / Range | Why It Matters |

|---|---|---|

| DC Input Voltage | 12V / 24V / 48V DC | Must match the cabinet’s power bus (e.g., 48V for telecom, 12V/24V for battery systems). Mismatched voltage will cause immediate failure. |

| Nominal Cooling Capacity | 100W – 900W (varies by model) | The primary performance metric. Must exceed the total heat load of the cabinet to be effective. Undersizing is the most common design error. |

| Refrigerant | R134a / R290 / R1234yf | Determines thermal performance and environmental compliance. R134a is a standard, while others may be required for specific regulations or performance goals. |

| Control System | Integrated PCB with variable-speed control | Inverter-driven compressors and fans are far more efficient than on/off systems, reducing power consumption and thermal cycling stress. |

| Example Model (24V) | DV1920E-AC (Pro) | Provides a concrete reference: 450W nominal cooling on a 24V DC bus using R134a refrigerant. |

| Example Model (48V) | DV1930E-AC (Pro) | Shows a similar 450W capacity but for a 48V DC system, common in telecom infrastructure. |

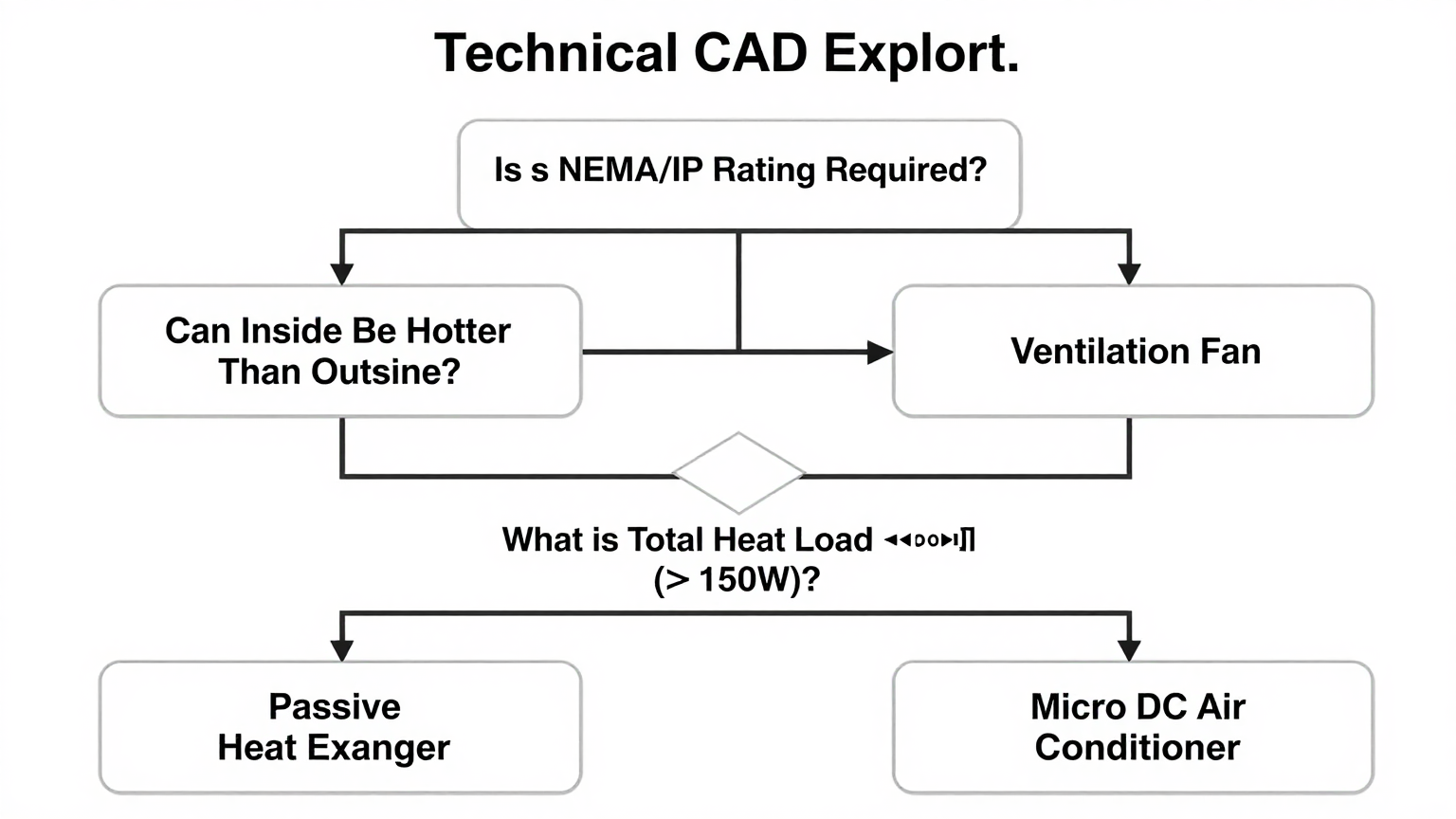

Engineering Selection Matrix: Logic Gates for Integration

Choosing the right thermal solution requires passing through a series of engineering logic gates. Answering these questions in order prevents over-engineering or, more dangerously, under-engineering the system.

1. The Sealing Gate: Is a NEMA/IP Rating Required?

- Constraint Gate: Environmental Exposure vs. Component Sensitivity. The system must be protected from dust, moisture, salt spray, or vandalism.

- Decision Trigger: If the enclosure requires a rating of IP55 or higher (or NEMA 3/4/12), any solution that requires venting ambient air is immediately disqualified.

- Engineering Resolution: The choice is narrowed to two options: a passive heat exchanger or an active vapor-compression system. This is the fundamental micro dc aircon vs ventilated cabinet decision point.

- Integration Trade-off: Committing to a sealed design increases upfront cost and complexity but eliminates the primary cause of field failures and the need for filter maintenance.

2. The Thermal Delta Gate: Can the Inside Be Hotter Than the Outside?

- Constraint Gate: Maximum Allowable Internal Temperature vs. Maximum Expected Ambient Temperature.

- Decision Trigger: If the internal cabinet temperature must be kept at or below the external ambient temperature, a heat exchanger is not a viable option. Heat exchangers can only keep the inside slightly warmer than the outside.

- Engineering Resolution: An active, refrigerated system like a micro dc air conditioner outdoor cabinet is now mandatory. It is the only technology that can create a negative thermal delta (making the inside cooler than the outside).

- Integration Trade-off: This moves the system from a passive to an active one, requiring a dedicated DC power budget for the compressor and fans. However, it guarantees a stable internal operating environment regardless of external heat waves.

3. The Heat Flux Gate: What is the Total Heat Load?

- Constraint Gate: Cooling Capacity vs. Total Heat Load (Internal Electronics + Solar Gain).

- Decision Trigger: Calculate the total heat load in watts. If this value exceeds ~100-150W, thermoelectric (Peltier) coolers become highly inefficient and impractical. For loads from 150W to 900W, vapor-compression air conditioning is the most efficient technology.

- Engineering Resolution: Select a micro dc air conditioner outdoor cabinet with a nominal cooling capacity that exceeds the calculated total heat load by a safety margin of at least 20-25% to account for unforeseen conditions and component aging.

- Integration Trade-off: A higher capacity unit may have a larger physical footprint and higher peak power draw. This must be factored into the cabinet’s mechanical design and the power supply’s rating. For more information on specific solutions, see our overview of Micro DC Aircon products.

Implementation Checklist for a Panel Mount Micro DC Air Conditioner Outdoor Unit

Proper installation is as critical as proper selection. A perfectly specified unit can fail if installed incorrectly. Follow this checklist to ensure reliability.

-

Mechanical Integration

- Surface Preparation: Ensure the cabinet’s mounting surface is flat, clean, and free of burrs. An uneven surface will compromise the seal.

- Gasket Integrity: Use the supplied gasket. Ensure it is fully compressed evenly around the perimeter of the unit by following the specified torque pattern for the mounting bolts. Do not overtighten.

- Airflow Pathways: Verify that the internal and external fans are completely unobstructed. Ensure no wiring harnesses, brackets, or other components are placed within 5-10 cm of the air intake or exhaust for both air circuits.

-

Electrical Connection

- Power Budget: Confirm the DC power supply or bus can handle the air conditioner’s maximum (startup) current, not just its nominal running current.

- Wire Gauge & Protection: Use the recommended wire gauge for the specified current and distance from the power source. Install an appropriately rated fuse or circuit breaker as close to the power source as possible.

- Polarity Check: DC systems are unforgiving. Double-check the polarity of the power connections before energizing the unit. Reverse polarity will permanently damage the control board.

-

Thermal Validation

- Sensor Placement: Place an independent temperature sensor in the upper third of the cabinet, away from direct airflow from the air conditioner’s cold air outlet. This provides a realistic measurement of the average internal ambient temperature.

- Acceptance Test: After installation, run the system under its maximum expected electrical load. Let the micro dc air conditioner outdoor cabinet run for at least one hour to confirm it can maintain the target temperature. If possible, perform this test on a warm, sunny day to simulate real-world conditions.

-

Maintenance Planning

- External Coil Inspection: Schedule a visual inspection of the external (condenser) coils every 6-12 months. In dusty or polluted environments, they may need to be cleaned with compressed air or a soft brush to maintain efficiency.

- Condensate Management: Ensure any condensate drain lines are clear and properly routed away from sensitive areas.

Frequently Asked Questions (FAQ)

Should I choose a heat exchanger or a micro DC air conditioner?

A heat exchanger is only suitable if you can tolerate the internal temperature being several degrees warmer than the maximum outside temperature. If you need the inside to be the same as or cooler than the ambient temperature, a micro dc air conditioner outdoor cabinet is your only option.

What happens to the IP/NEMA rating when I install a cooling unit?

A properly installed, panel-mounted unit is designed to maintain the enclosure’s seal. The unit itself has two separate air paths, and the gasket between the unit and the cabinet wall preserves the integrity of the enclosure. This is a key advantage over ventilated solutions, which inherently compromise the rating.

Will a micro DC air conditioner create condensation inside my cabinet?

No, not if the cabinet is properly sealed. Condensation forms when warm, moist air comes into contact with a cold surface. Because a micro dc aircon sealed outdoor enclosure uses a closed loop, it only cools the dry air already inside. It removes moisture during the initial cooldown, which is then managed by the unit’s external drainage system. It does not introduce new, moist air.

How do I account for direct sun, dust, or salt fog?

For direct sun, you must add the solar heat load to your total cooling calculation. A solar shield or painting the cabinet a light, reflective color can help reduce this load. For dusty or corrosive environments, the sealed-enclosure design of a micro dc air conditioner outdoor cabinet is the primary defense, as it prevents those contaminants from ever reaching the electronics.

What is the single most important measurement I need to take first?

You need two: the total power dissipation (in watts) of all internal components, and the maximum expected ambient temperature combined with an assessment of solar exposure. Without an accurate heat load calculation, any choice of cooling solution is just a guess.

How can I validate the cooling performance after installation?

Log the internal cabinet temperature over a 24-hour cycle during the hottest time of the year. Compare the temperature profile to the operating limits of your most sensitive components. The temperature should remain stable and well below the maximum limit, even during peak solar load in the afternoon.

Conclusion: Matching the Tool to the Environment

The decision to use a micro dc air conditioner outdoor cabinet is not about over-engineering; it’s about risk mitigation. While fans and vents have their place in benign, climate-controlled environments, they are a liability for sealed outdoor enclosures exposed to the elements. The combination of solar load, internal heat generation, and the non-negotiable need for a sealed enclosure creates a scenario where active, closed-loop cooling is the only reliable engineering solution.

This approach is the best fit when long-term reliability is paramount, maintenance access is limited or costly, and the enclosed electronics are critical to operations. It is not the right fit for applications where venting is acceptable and the ambient environment is clean and cool. By progressing through the logic gates of sealing, thermal delta, and heat flux, an engineer can confidently specify a system that ensures zero-derating of electronics and maximizes the service life of critical infrastructure. A robust thermal management strategy is the foundation of a reliable outdoor system.

If you are facing challenges with outdoor electrical cabinet overheating sun load or need to size a cooling solution for a specific enclosure geometry and power constraint, our engineering team can help. Contact us to discuss your project’s unique thermal requirements.

0 条评论