Angle: The critical decision is choosing between a simple fan, a thermoelectric cooler (TEC), and a compressor-based system for a sealed NEMA-style enclosure. The primary failure modes are electronics derating from heat and condensation causing short circuits. The dominant constraint is maintaining a verified IP/NEMA seal while actively cooling below ambient temperature.

A Guide to Sealed Enclosure Cooling Technology; Fans vs TEC vs Compressor

An industrial controller in a sealed cabinet on a hot factory floor silently overheats and fails, bringing a production line to a halt. A remote telecom installation throttles its data throughput on a sunny afternoon because its electronics are derating. These are not hypothetical scenarios; they are costly realities driven by inadequate thermal management. The root cause is often a mismatch between the cooling solution and the operational environment. Choosing the right sealed enclosure cooling technology; fans vs tec vs compressor, is not just about temperature—it’s about reliability, uptime, and protecting the capital investment inside the box.

By the end of this technical guide, you will have a clear engineering framework for deciding when a simple fan is insufficient, when a thermoelectric cooler is a viable option, and when the physics of your application demand a move to active, compressor-based cooling. In this analysis, we prioritize long-term system reliability and maintaining the enclosure’s environmental seal over minimal upfront cost, because field failures are almost always more expensive than getting the thermal design right from the start.

Deployment Context: Two Common Scenarios

The need for robust thermal management appears in countless applications. Here are two distinct scenarios where the choice of cooling technology is critical.

Scenario A: Factory Floor Automation Cabinet

A sealed NEMA-12 cabinet houses a variable frequency drive (VFD) and a PLC controlling a critical CNC machine. The environment is contaminated with metallic dust and aerosolized cutting fluids, making a perfect seal non-negotiable. The initial design used a simple filtered fan, but the filters clogged within weeks, causing the VFD to trip on over-temperature faults. An undersized thermoelectric cooler was then installed, but it couldn’t cope with the 45°C ambient factory temperature combined with the VFD’s significant heat load, leading to intermittent shutdowns during peak production hours.

Scenario B: Outdoor Telecom & Edge Compute Node

A remote 5G base station is housed in a NEMA-4X enclosure in a desert environment, sealed against dust and rain. The cabinet is subject to intense solar load, pushing the internal temperature far above the already high ambient. Passive cooling via a heat exchanger proved insufficient, causing the sensitive radio equipment to throttle performance to protect itself. The key constraints are the extreme ambient temperature, the need to maintain a water-tight seal, and the reliance on a 48V DC power bus from a battery backup system. This is a classic challenge for any sealed enclosure cooling technology; fans vs tec vs compressor.

Common Failure Modes & System Constraints

When thermal management is an afterthought, the symptoms manifest in predictable and damaging ways. Understanding these failure modes is the first step in selecting the right solution.

- Symptom: Gradual performance degradation → Cause: Thermal throttling of CPUs/processors → Why it matters: Reduced system output, unpredictable behavior, and compromised service levels.

- Symptom: Abrupt system shutdown → Cause: A critical component’s temperature exceeds its maximum safety limit → Why it matters: Unplanned downtime, potential data corruption, and costly emergency service calls.

- Symptom: Water dripping inside the cabinet → Cause: Cooling the internal air below its dew point without proper condensate management → Why it matters: Catastrophic short circuits, corrosion, and permanent hardware damage.

- Symptom: Clogged filters and dust-coated components → Cause: Using filtered fans in a dirty environment, which compromises the seal → Why it matters: Increased maintenance cycles, reduced cooling effectiveness, and eventual component failure.

- Symptom: Excessively high energy bills → Cause: Using inefficient cooling technology, like TECs at a large temperature differential → Why it matters: Increased operational expenditure (OpEx), especially in large-scale deployments.

- Symptom: Premature component failure → Cause: Operating electronics consistently at the high end of their specified temperature range → Why it matters: Drastically reduced Mean Time Between Failures (MTBF), leading to increased warranty claims and reputational damage.

- Symptom: Loss of IP/NEMA rating → Cause: Cutting incorrect openings for fans or unsealed cooling units → Why it matters: Voids enclosure warranty and exposes sensitive electronics to the very contaminants the enclosure was meant to block.

Engineering Fundamentals of Closed-Loop Cooling

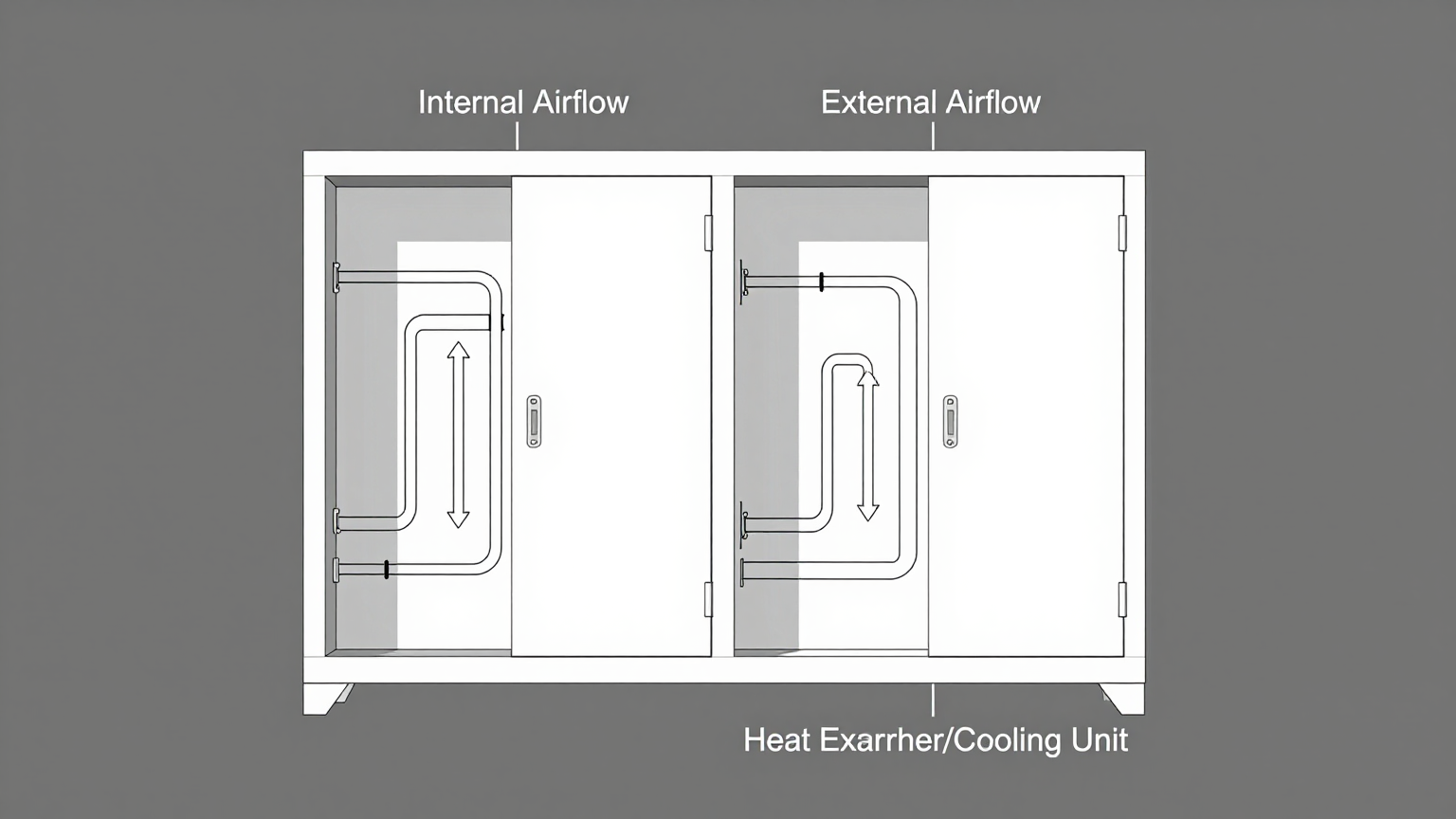

The core principle of cooling a sealed enclosure is the concept of closed-loop cooling. The goal is to remove heat from the internal environment without exchanging the internal air with the ambient air. This maintains the integrity of the seal, keeping dust, moisture, and corrosive elements out. The heat path is simple: heat generated by components is transferred to the internal air, and a cooling system must then remove that heat from the internal air and reject it to the outside environment.

This immediately highlights a critical distinction:

- Passive/Ambient Cooling (Fans, Heat Exchangers): These technologies can only keep the internal temperature above the ambient temperature. They rely on a positive temperature differential (delta-T) to function. A fan simply moves air; a heat exchanger uses that differential to move heat across a barrier. They cannot cool to or below the ambient temperature.

- Active/Refrigerated Cooling (TECs, Vapor-Compression): These technologies use energy to create a temperature differential, allowing them to cool the internal temperature below the ambient temperature. This is essential when sensitive electronics must be kept at a stable 25-35°C even when the outside air is 40-50°C.

A common misconception among designers new to this space is that “more airflow is always the solution.” This is incorrect. In a sealed system, airflow is about circulation to eliminate hot spots, not exchange. The fundamental mistake is to compromise the seal for more airflow. This act negates the purpose of a sealed enclosure, introducing humidity and contaminants that lead to the failure modes listed above. The right approach is to select a sealed enclosure cooling technology; fans vs tec vs compressor that respects the closed-loop principle.

Key Specifications for Active Cooling Systems

When evaluating active cooling solutions like the Micro DC Aircon series, certain specifications are non-negotiable for making an informed decision. The table below shows example parameters for several models. When reading these specs, focus on how they align with your project’s constraints. Nominal Cooling Capacity is the headline figure, but it must be derated based on your maximum ambient temperature. The DC Voltage determines how it integrates with your power bus, which is critical for telecom or mobile applications. These are not off-the-shelf residential units; they are industrial components designed for specific integration challenges.

| Model (Example) | Voltage | Nominal Cooling Capacity | Refrigerant |

|---|---|---|---|

| DV1910E-AC (Pro) | 12V DC | 450W | R134a |

| DV1920E-AC (Pro) | 24V DC | 450W | R134a |

| DV1930E-AC (Pro) | 48V DC | 450W | R134a |

| DV3220E-AC (Pro) | 24V DC | 550W | R134a |

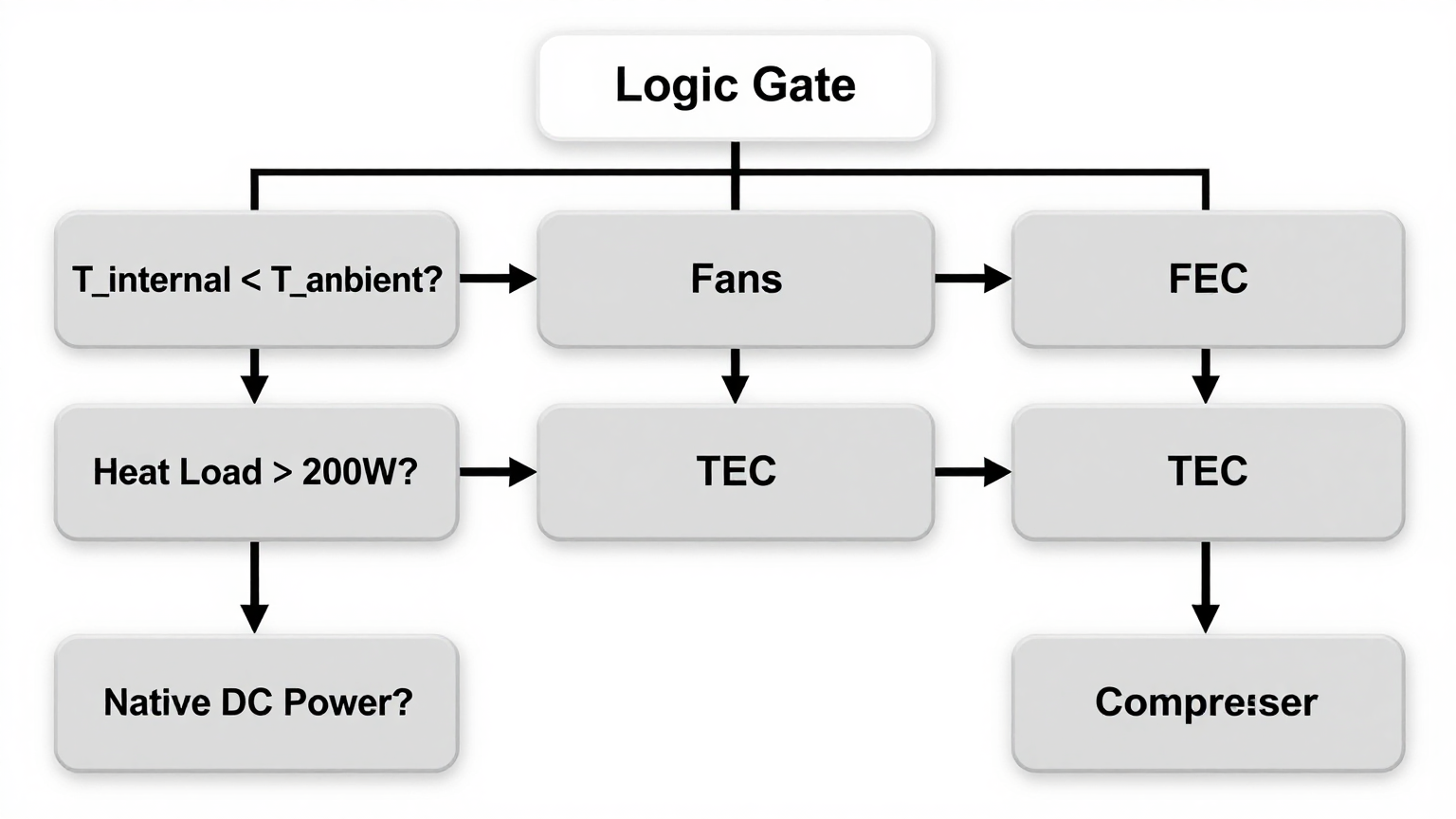

Engineering Selection Matrix: Logic Gates for Decision-Making

An engineer’s selection process is a series of logic gates. If a condition is met, it closes one path and opens another. Here is a practical matrix for choosing your sealed enclosure cooling technology; fans vs tec vs compressor.

Logic Gate 1: Ambient Temperature vs. Required Internal Temperature

- The Constraint Gate: Can the internal components reliably operate at a temperature several degrees above the maximum possible ambient temperature?

- The Decision Trigger: If the required maximum internal temperature is less than or equal to the maximum ambient temperature (T_internal ≤ T_ambient), passive cooling is physically impossible. For example, if components must be kept below 35°C but the factory floor can reach 45°C.

- Engineering Resolution: The system requires active, refrigerated cooling. This immediately rules out fans and heat exchangers. The decision is now narrowed to Thermoelectric (TEC) vs. Vapor-Compression (Compressor).

- Integration Trade-off: This is a major decision point. It moves the project from requiring a simple sheet metal cutout for a fan to integrating a more complex electromechanical subsystem with power and condensate management needs.

Logic Gate 2: Total Heat Load vs. Cooling Technology Efficiency (COP)

- The Constraint Gate: What is the total heat load in watts that must be removed? This includes all heat generated by internal components plus any external solar load on the enclosure’s surface.

- The Decision Trigger: For total heat loads above approximately 200 watts, or when the required temperature difference (delta-T between ambient and internal) exceeds 15-20°C, the Coefficient of Performance (COP) of solid-state TECs drops dramatically. They consume a large amount of power to move a small amount of heat.

- Engineering Resolution: Miniature vapor-compression systems, such as the Micro DC Aircon series, become far more energy-efficient. Their COP is significantly higher under these conditions, meaning they remove more heat per watt of input power.

- Integration Trade-off: A compressor-based system typically has a higher initial cost and a larger physical footprint than a TEC for the same low-end cooling capacity. However, it drastically reduces long-term operating costs (power consumption) and can handle heat load spikes that would overwhelm a TEC.

Logic Gate 3: Power Source & Budget Constraints

- The Constraint Gate: Is the available power AC or DC? What is the total power budget in watts?

- The Decision Trigger: In remote, battery-backed, or vehicle-mounted applications (like the telecom cabinet scenario), a native DC power source is often the only option. Using an inverter to convert DC to AC to power a conventional AC air conditioner is highly inefficient.

- Engineering Resolution: This constraint heavily favors native DC solutions. Both TECs and specialized DC compressor systems are designed for this. The Micro DC Aircon series, with its 12V, 24V, and 48V DC input options, is purpose-built for these applications, eliminating the energy waste and failure point of a separate inverter.

- Integration Trade-off: Designing for a native DC bus simplifies the overall power architecture and improves system reliability. It requires careful component selection to match the bus voltage but results in a more robust and efficient final product. This is a key consideration when comparing any sealed enclosure cooling technology; fans vs tec vs compressor.

Implementation & Verification Checklist

Selecting the right technology is only half the battle. Proper integration is critical for performance and reliability.

- Mechanical Integration

- Mounting: Ensure the cooling unit is securely fastened according to the manufacturer’s specifications, paying attention to vibration isolation if required.

- Sealing: Use the correct gasket and follow the recommended torque sequence for all fasteners. The seal between the cooler’s mounting flange and the enclosure wall is the most critical point for maintaining the IP/NEMA rating.

- Airflow Integrity: Verify that no internal cables, brackets, or components are blocking the cold air outlet or the return air inlet. A short-circuit in the airflow path will cripple performance. Ensure the external condenser fins have several inches of clearance for unobstructed heat rejection.

- Electrical Integration

- Power Supply: Use appropriately gauged wires to handle the current draw, especially for high-current 12V systems, to prevent voltage drop.

- Circuit Protection: Install the manufacturer-recommended fuse or circuit breaker in-line with the power source.

- Control Wiring: If using an external thermostat or remote control signals, ensure the wiring is correct and shielded if necessary to prevent electrical noise interference.

- Thermal Validation

- Sensor Placement: Place validation thermocouples near the most heat-sensitive components and at the top of the enclosure (where hot air collects), not just at the cooling unit’s air outlet.

- Acceptance Test: After installation, run the entire system under full electrical load on a warm day (or in a thermal chamber) to confirm it maintains the target internal temperature. Log the temperature over time to verify stability.

Frequently Asked Questions (FAQ)

- 1. What’s the main difference between a TEC and a Micro DC Aircon?

- The primary difference is efficiency (COP) and capacity. TECs are simple and reliable for very low heat loads (under 100-200W) and small temperature differences. As heat load or delta-T increases, vapor-compression systems like a Micro DC Aircon become vastly more efficient, using significantly less power to move the same amount of heat.

- 2. How do I manage condensation if I’m cooling below the ambient dew point?

- Proper condensate management is built into well-designed active coolers. They will have a drain port to route moisture outside the enclosure. Critically, the enclosure must be perfectly sealed. Any air leak will continuously introduce new moisture, overwhelming the system and causing internal water buildup.

- 3. My enclosure is in direct sunlight. How does that affect my choice?

- Direct sun adds a significant external heat load (solar load) that can be several hundred watts. You must calculate this and add it to your internal heat load. This often pushes the total required cooling capacity high enough that a vapor-compression system is the only viable option.

- 4. What is the most important measurement I need before selecting a cooler?

- Two numbers are critical: 1) The total internal heat load of your components in watts. 2) The maximum expected ambient temperature at the installation site. Without these, any selection is just a guess.

- 5. Can I use a fan if my enclosure is rated NEMA 4 / IP66?

- You can only use a fan for internal air circulation (a stirring fan) to break up hot spots. Any fan that creates an opening to exchange air with the outside environment will immediately violate the NEMA 4 / IP66 rating.

- 6. How do I validate the cooling performance after installation?

- The best method is data logging. Place thermocouples on key components, run the system under full load, and record the temperatures over several hours during the hottest part of the day. Compare this data against the component’s maximum allowable operating temperature.

- 7. What is the best sealed enclosure cooling technology; fans vs tec vs compressor?

- There is no single “best.” The best technology is the one that meets the specific requirements of your application. Fans are for when T_internal can be > T_ambient and the environment is clean. TECs are for low heat loads where you need to go below ambient. Compressor-based systems are for moderate-to-high heat loads, high ambient temperatures, and energy efficiency at scale.

Conclusion: Making the Best-Fit Decision

The decision process for sealed enclosure cooling technology; fans vs tec vs compressor, is a trade-off between cost, performance, and environmental reality. If your internal components can run hotter than the maximum ambient temperature and the air is clean, a simple fan may suffice. If you must hold a temperature at or below ambient, you require active cooling.

From there, the choice between a TEC and a miniature vapor-compression system is a matter of physics and efficiency. For low heat loads (typically <200W) and small temperature differentials, a TEC offers simplicity. For higher heat loads, high ambient temperatures, or applications where energy efficiency is paramount, the superior Coefficient of Performance of a miniature DC compressor system is the clear engineering choice. These systems are the best fit for demanding industrial, telecom, and mobile applications where reliability is non-negotiable and the cost of failure is high.

For a detailed thermal analysis of your specific enclosure geometry, heat load, and environmental constraints, contact our engineering team to discuss custom mounting, power profiles, and selecting the right sealed enclosure cooling technology; fans vs tec vs compressor for your project.

0 条评论