The Forensic Path: When Passive Venting Becomes a Liability

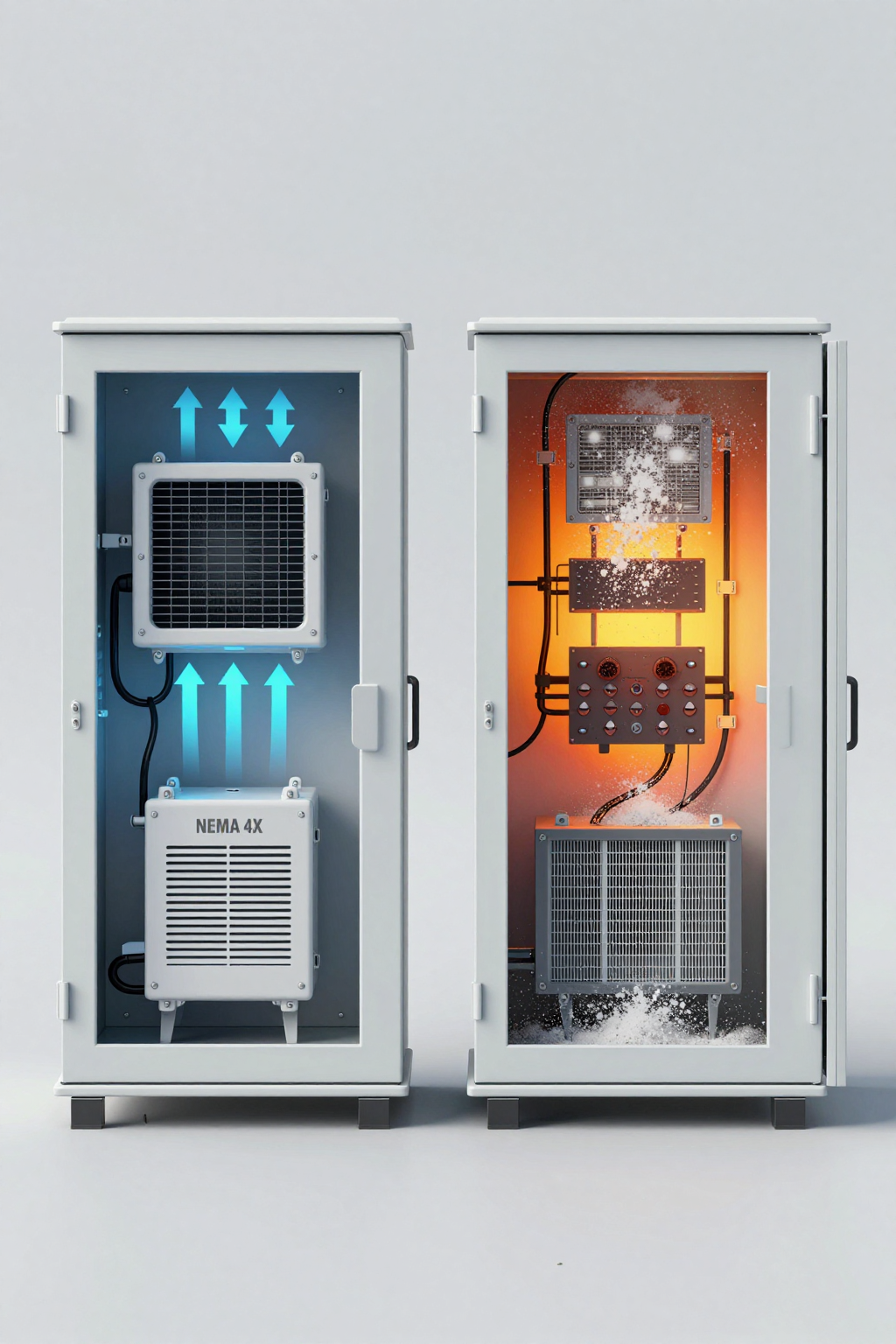

The failure usually happens at 2:00 PM on a Tuesday in July. A high-visibility outdoor kiosk—perhaps a parking payment terminal in Phoenix or a digital signage unit in Dubai—goes dark. The screen is black, the transaction module is unresponsive, and the technician arriving on-site measures an internal enclosure temperature exceeding 65°C (149°F). The diagnosis is rarely a defective component in isolation; it is a systemic failure of thermal strategy. The enclosure was sealed to NEMA 4 standards to prevent dust ingress, but the cooling method relied on passive dissipation or undersized heat exchangers that could not overcome the solar load.

For OEM engineers and system integrators, this scenario represents the critical juncture where sealed outdoor enclosure cooling tradeoffs must be re-evaluated. The decision to move from passive or fan-based cooling to active refrigeration is often delayed due to perceived complexity or cost. However, when the cost of downtime, component degradation, and emergency field service is calculated, active cooling is justified. This article analyzes the engineering logic behind this transition, focusing on the specific thermal dynamics of harsh outdoor environments and the role of miniature vapor-compression systems.

Deployment Context: The Hostility of the “Smart City”

The modern outdoor enclosure is no longer just a junction box; it is a dense compute node. Whether it is an EV charging station, a 5G small cell, or an interactive wayfinding kiosk, these systems share a common operational profile: they generate significant internal heat while sitting in environments that actively attack them.

Consider a deployment in a coastal industrial zone. The ambient air is laden with salt spray and conductive dust. The enclosure must be sealed (NEMA 4X / IP66) to prevent corrosion on the PCBs. However, sealing the enclosure traps the heat generated by the power supply, CPU, and display backlight. If the ambient temperature is 40°C, a sealed box with a 200W internal load can easily reach internal temperatures of 70°C or higher without active intervention. In this context, the sealed outdoor enclosure cooling tradeoffs shift dramatically. The “free cooling” of ambient air is no longer an option because admitting that air destroys the electronics. The only viable path is a closed-loop system that actively pumps heat out.

Technical Friction Points: The Unseen Enemies of Uptime

Why do standard cooling approaches fail in these scenarios? The failure modes are often driven by physics that are ignored during the initial design phase.

- The Delta-T Trap: Passive heat exchangers and fans rely entirely on the temperature difference (Delta T) between the inside and outside. As the ambient temperature rises to meet the maximum allowable internal temperature, cooling capacity drops to zero. In a 45°C ambient environment, a fan cannot cool a cabinet to 40°C. It is physically impossible.

- Solar Loading Spikes: Direct sunlight can add 800–1000 W/m² of thermal load. For a dark-colored kiosk, this solar gain can double the effective cooling requirement, pushing passive systems into thermal runaway.

- Humidity and Condensation: In environments with high diurnal temperature swings, air inside a non-active enclosure can reach the dew point as the casing cools at night. This leads to internal condensation, shorting sensitive control boards. Active cooling systems with dehumidification capabilities mitigate this risk.

- Filter Maintenance Debt: “Open loop” cooling with fans and filters requires regular site visits to change clogged filters. In remote locations, this OpEx quickly exceeds the CapEx of a sealed, maintenance-free active system.

Engineering Fundamentals: The Logic of Active Cooling

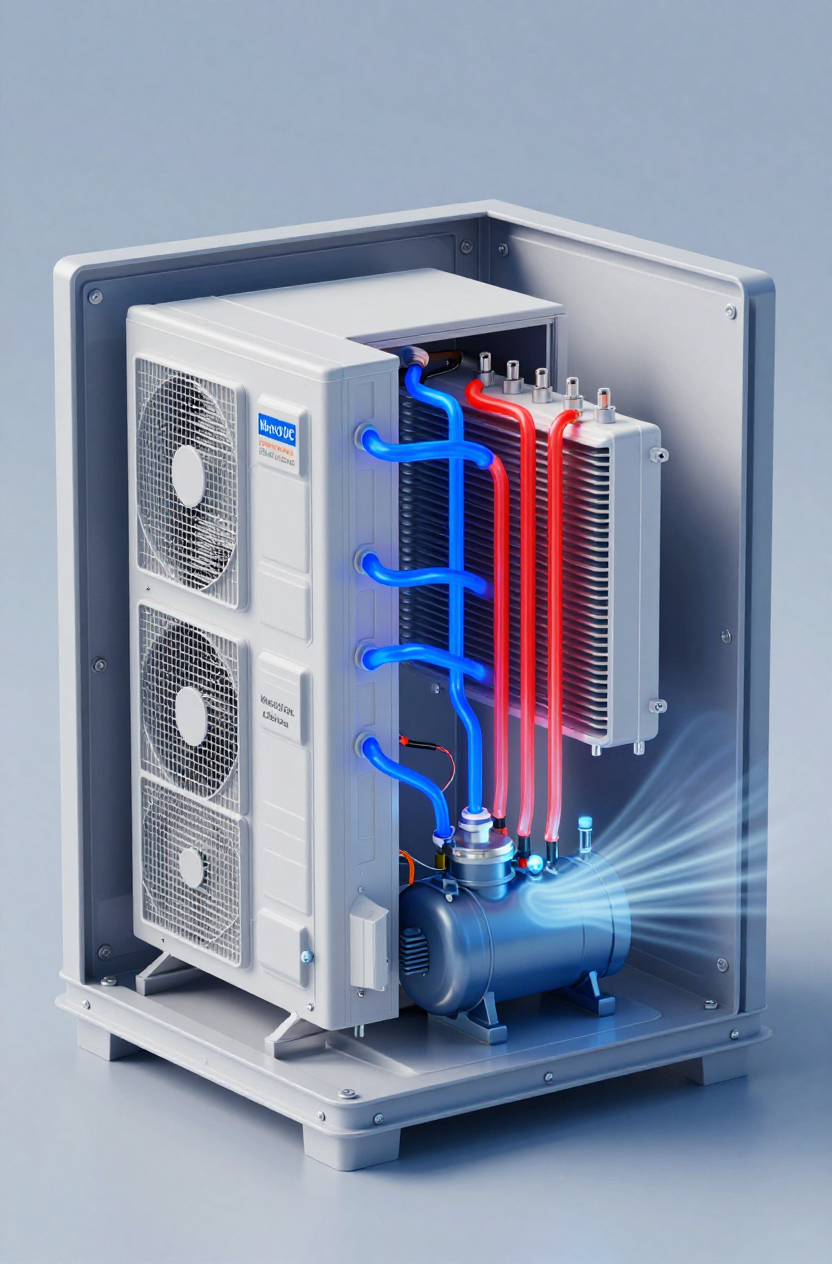

To understand why active cooling is justified in these high-stakes applications, we must look at the mechanism of heat removal. Active cooling, specifically vapor-compression refrigeration, does not rely on a favorable ambient temperature. Instead, it uses energy to pump heat “uphill”—from the cool interior to the hot exterior.

The Vapor-Compression Advantage

Unlike thermoelectric (Peltier) coolers, which are inefficient and struggle with loads above 100W, a vapor-compression system uses a refrigerant cycle to absorb and reject heat. The key components—compressor, condenser, expansion valve, and evaporator—work together to maintain a setpoint regardless of the outside weather.

In a Micro DC Aircon system, the evaporator coil absorbs heat from the enclosure air. The refrigerant boils, carrying the thermal energy to the compressor. The compressor increases the pressure and temperature of the gas, allowing it to reject heat to the outside air via the condenser coil, even if it is 50°C outside. This decoupling of internal performance from external conditions is the primary reason active cooling is justified for critical infrastructure.

Closed-Loop Isolation

The secondary benefit is environmental isolation. By recirculating the same clean, dry air inside the cabinet, the system eliminates the ingress of dust, moisture, and chemical contaminants. This creates a “clean room” environment for the electronics, significantly extending the MTBF (Mean Time Between Failures) of the expensive components inside.

Performance Data & Verified Specs

For engineers sizing a solution, the transition to active cooling requires evaluating cooling capacity (Watts/BTU) against power consumption. Arctic-tek’s Micro DC Aircon series utilizes miniature BLDC rotary compressors to deliver high cooling density in a compact footprint. The following specifications highlight the capabilities of the DV series, which are often employed in these scenarios.

| Model (Example) | Voltage | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC | 12V DC | 450W | R134a | BLDC Inverter Rotary |

| DV1920E-AC | 24V DC | 450W | R134a | BLDC Inverter Rotary |

| DV1930E-AC | 48V DC | 450W | R134a | BLDC Inverter Rotary |

| DV3220E-AC | 24V DC | 550W | R134a | BLDC Inverter Rotary |

These units feature integrated driver boards for inverter control, allowing the system to modulate speed based on thermal load. This variable-speed operation is crucial for battery-powered or solar-supported applications where energy efficiency is paramount. For specific integration details, engineers can review our Micro DC Aircon solutions.

Field Implementation Checklist: Best Practices

Deploying an active cooling system requires a holistic design approach. The following checklist outlines the critical steps for a successful integration.

Mechanical & Structural

- Insulation is Mandatory: Active cooling is wasted if the enclosure walls conduct heat freely. Use closed-cell foam insulation to minimize solar gain and prevent thermal bridging.

- Airflow Management: Ensure the cold air discharge is not short-cycling back into the intake. Use baffles or ducting to direct cool air toward the hottest components (e.g., the CPU or power supply).

- Condensate Routing: Active cooling removes moisture. Ensure the condensate drain line is routed correctly to the exterior and includes a trap to prevent insect ingress.

Electrical & Control

- Voltage Matching: Select a unit that matches your primary DC bus (12V, 24V, or 48V) to avoid the efficiency loss of DC-DC converters.

- Hysteresis Settings: Configure the thermostat with appropriate hysteresis (e.g., 2°C–4°C) to prevent rapid cycling of the compressor, which can shorten its lifespan.

Expert Field FAQ

Q: If the ambient temperature is lower than the internal target, why can’t I just use a fan?

A: You can, but you lose the NEMA/IP rating integrity. Fans introduce dust and humidity. Furthermore, if the ambient temperature spikes (even for a few hours), a fan system has no reserve capacity to handle the load, leading to thermal shutdown. In high-value systems, the risk of contamination and thermal spikes usually means active cooling is justified.

Q: How does the Micro DC Aircon handle vibration in mobile kiosks?

A: The rotary compressors used in the DV series are inherently more robust against vibration than reciprocating compressors. However, for mobile applications, we recommend using vibration-damping mounts to isolate the cooling unit from the chassis.

Q: What happens to the IP rating during maintenance?

A: Unlike filter-based systems that require the cabinet to be opened for cleaning, a closed-loop air conditioner allows the cabinet to remain sealed. Maintenance is generally limited to cleaning the external condenser coil, which does not breach the sealed compartment.

Q: Can these units run directly off solar panels?

A: Yes, but a battery buffer is required. The compressor needs a stable voltage source. The system is designed to run on DC power, making it ideal for off-grid solar applications where avoiding an inverter (DC to AC) saves significant energy.

Q: Is R134a the only refrigerant option?

A: While R134a is standard for many models like the DV1920E-AC, we also support platforms using R290 and R1234yf for regions with stricter GWP (Global Warming Potential) regulations. Consult the specific series data for availability.

Q: How do I size the unit for solar loading?

A: Solar load is significant. A standard calculation involves the surface area exposed to the sun, the color of the enclosure, and the insulation value. We recommend treating solar load as an addition to the internal heat dissipation. For precise sizing, consider our DC condensing units for custom evaporator configurations if standard units do not fit.

Conclusion & System Logic

The decision to implement active cooling in outdoor enclosures is fundamentally a decision about reliability. While passive methods offer a lower upfront cost, they expose critical electronics to the variables of weather, pollution, and extreme heat. When analyzing sealed outdoor enclosure cooling tradeoffs, the data consistently shows that for systems requiring high uptime in harsh environments, active cooling is justified.

By utilizing miniature DC vapor-compression technology, engineers can decouple their system’s internal environment from the chaos of the outside world. This ensures that whether the kiosk is in a desert or a coastal city, the electronics operate within a stable, clean, and cool environment. For specific thermal modeling or to discuss which Micro DC Aircon series fits your voltage and capacity requirements, consult the Arctic-tek engineering team.

0 条评论