The Engineer’s Sizing Guide to Micro DC Air Conditioners for Electronics Enclosures

You’ve packed high-power-density electronics into a compact, sealed enclosure, but now you’re facing the consequences: thermal throttling, component degradation, and even total system failure. Relying on guesswork or oversized, inefficient cooling solutions wastes power, space, and money. This guide provides a clear, calculation-based framework to correctly size a micro DC air conditioner, ensuring your critical electronics remain stable and reliable, even in demanding environments.

Key Takeaways

- Internal Heat Load First: The primary heat source is your electronics. Accurately calculating this value (in watts) is the foundation of a reliable thermal management strategy.

- Don’t Ignore External Factors: Heat gain through enclosure walls (conduction) and solar load on outdoor units are significant factors that can push your system past its thermal limits.

- ΔT Drives Everything: The temperature difference (ΔT) between your maximum allowable internal temperature and the peak external ambient temperature dictates the real-world performance of any cooling unit.

- COP Matters More Than BTUs Alone: A higher Coefficient of Performance (COP) means more cooling power for every watt of electrical input. For DC-powered applications, this efficiency is paramount. A typical micro vapor compression system can achieve a COP of 2.0-4.0, whereas a Peltier/thermoelectric cooler is often limited to 0.4–0.8 in similar conditions.

- Voltage Matching is Non-Negotiable: Sizing a cooling unit must include matching its power system (e.g., 12V, 24V, or 48V DC) to your application’s power bus to ensure compatibility and efficiency.

The 5-Step Engineering Framework for Sizing Your Micro DC Aircon

Sizing a cooling unit isn’t black magic; it’s a methodical process. Follow these steps to move from assumptions to a precise cooling requirement.

Step 1: Calculate Internal Heat Load (Q_internal)

This is the heat generated by the components inside the enclosure. For most electronics, the power consumed is nearly equal to the heat generated.

Formula: Q_internal = P1 + P2 + P3 + ... (where P is the power consumption in watts of each component)

Example: An industrial controller (30W), a power supply (15W at 85% efficiency = 13W heat), and two servo drives (20W each) are in an enclosure.

Q_internal = 30W + 13W + (2 * 20W) = 83W

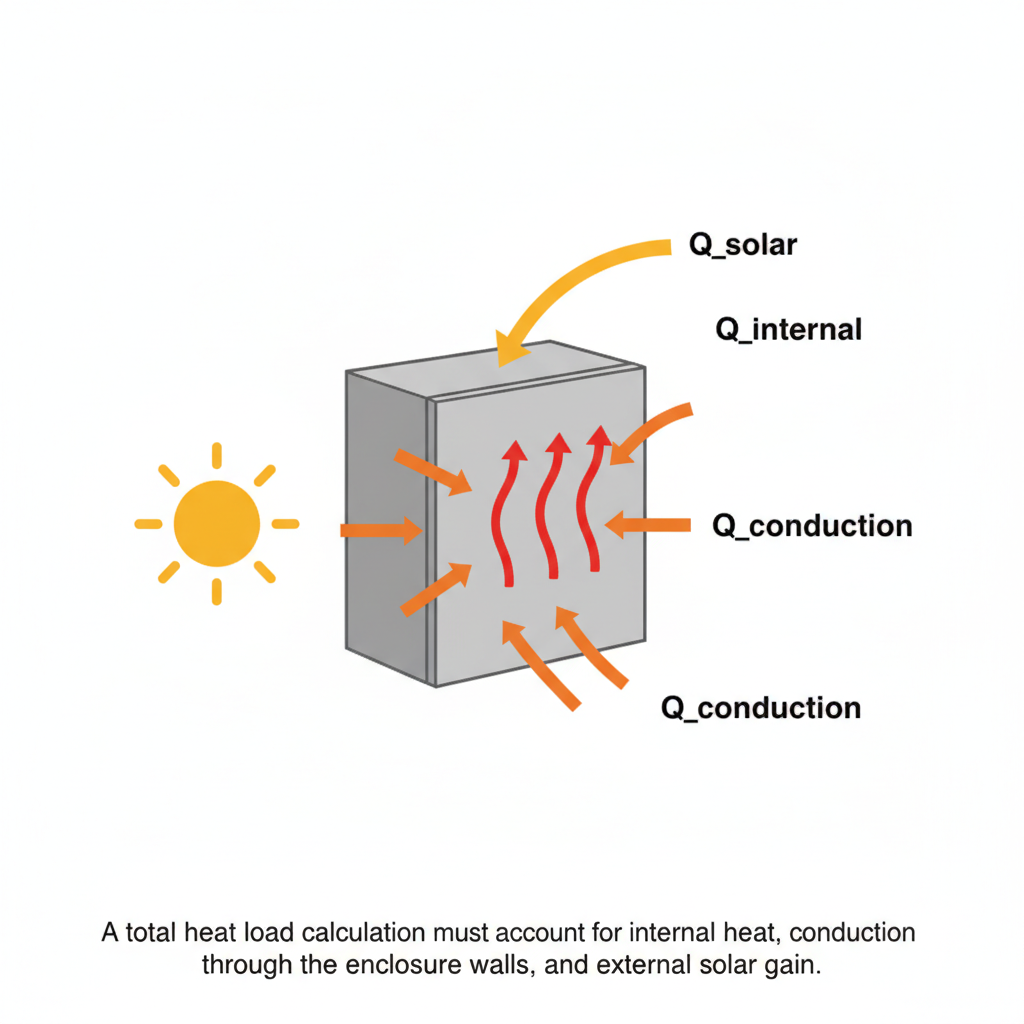

Step 2: Calculate Heat Transfer Through Enclosure Walls (Q_conduction)

Heat can leak into your enclosure from the outside environment. This is driven by the ΔT and the enclosure’s surface area and insulation properties.

Formula: Q_conduction = U * A * ΔT

- U: Heat transfer coefficient of the enclosure material (e.g., painted steel is ~5.5 W/m²°K).

- A: Exposed surface area of the enclosure in square meters.

- ΔT: The difference between max external ambient temp and your desired max internal temp (°C or °K).

Example: A 0.5m x 0.4m x 0.3m steel box (Area ≈ 0.94 m²) in a 45°C factory needs to maintain an internal temp of 35°C. (ΔT = 10°C)

Q_conduction = 5.5 W/m²°K * 0.94 m² * 10°K = 51.7W

For demanding applications, a dedicated micro DC aircon module provides the active cooling needed to manage this external heat load effectively.

Step 3: Calculate Solar Gain for Outdoor Enclosures (Q_solar)

For an outdoor cabinet exposed to direct sunlight, solar radiation adds a significant heat load. Don’t skip this for outdoor applications.

Formula: Q_solar = α * I * A_sun

- α: Solar absorptivity of the surface (e.g., 0.9 for dark paint, 0.25 for white).

- I: Solar radiation intensity (use a conservative value, e.g., 1000 W/m² for peak sunlight).

- A_sun: The surface area exposed to the sun (typically the top and one side).

Example: The same box, painted dark grey (α=0.8), with its top (0.5m*0.4m) and one side (0.5m*0.3m) in the sun.

A_sun = (0.5*0.4) + (0.5*0.3) = 0.35 m²

Q_solar = 0.8 * 1000 W/m² * 0.35 m² = 280W

Step 4: Calculate Total Heat Load (Q_total) and Apply a Safety Factor

Sum all the heat loads to find your minimum required cooling capacity. It’s standard practice to add a safety margin of 20-30% to account for component aging, potential system upgrades, and brief spikes in ambient temperature.

Formula: Q_total = (Q_internal + Q_conduction + Q_solar) * Safety_Factor

Example (Outdoor Scenario):

Q_total = (83W + 51.7W + 280W) * 1.25 = 518W

Your cooling system must be able to remove at least 518 watts of heat under the specified operating conditions.

Step 5: Select the Right Micro DC Air Conditioner

Now you can choose a unit. Look at the performance curves on the manufacturer’s datasheet. A cooler rated for “500W” may only provide 350W of cooling at your specific high-ambient ΔT. Select a model whose performance curve shows it can deliver your required Q_total at your maximum design ambient temperature. Ensure the voltage (12V, 24V, or 48V) matches your power system. The compact size of a miniature DC compressor is what makes these powerful micro-systems possible.

Frequently Asked Questions (FAQ)

- 1. What is the typical COP of a micro DC air conditioner vs. a Peltier cooler?

- A micro DC vapor compression air conditioner typically has a COP between 2.0 and 4.0, while a solid-state Peltier (thermoelectric) cooler struggles to exceed a COP of 0.8, especially at higher ΔT values. This means the DC aircon is 3-5 times more energy-efficient.

- 2. How does solar gain impact my cooling needs for an outdoor cabinet?

- Significantly. As shown in the example, solar load on a dark-colored metal box can add hundreds of watts to your total heat load, often becoming the single largest heat source to overcome.

- 3. Are fans enough for a sealed NEMA enclosure?

- No. Fans only circulate air; they cannot cool the internal temperature below the external ambient temperature. In a sealed enclosure, fans merely move hot air around. For a sealed box where internal temps must be lower than ambient, you need an active cooling technology like a portable DC air conditioner or a closed-loop system.

- 4. Why choose a 48V DC air conditioner?

- 48V DC is the standard for telecom and many modern industrial systems. Using a native 48V cooling unit eliminates the need for inefficient DC-DC converters, reducing system complexity, cost, and waste heat.

- 5. How much of a safety margin should I add when sizing?

- A minimum of 20-25% is recommended. This accounts for unforeseen variables, slight degradation in compressor performance over time, and potential future increases in internal heat load.

Conclusion: From Calculation to Implementation

By moving from a “guess and check” approach to a structured calculation, you can confidently specify a cooling solution that is both effective and efficient. Your next steps are straightforward:

- Audit Your Components: Create a definitive list of all heat-producing electronics and their power consumption.

- Define Your Environment: Lock down your maximum allowable internal temperature and the worst-case external ambient temperature.

- Run the Numbers: Use the framework above to calculate your total heat load including a safety factor.

- Select a Product: Compare your calculated `Q_total` to the performance data of a suitable design and OEM cooling solution, ensuring it performs under your specific ΔT.

0 条评论