The Invisible Enemy of Commercial Drone Operations

In the world of commercial UAVs—whether agricultural spraying, infrastructure inspection, or last-mile delivery—efficiency is measured in flight cycles per hour. The bottleneck is rarely the drone itself, or the pilot. It is the battery chemistry.

High-discharge Lithium Polymer (LiPo) and High Voltage Lithium (LiHV) packs generate significant internal heat during flight, often landing at core temperatures exceeding 55°C (131°F). Modern intelligent Battery Management Systems (BMS) are programmed with a strict safety protocol: Thermal Lockout. The BMS will physically prevent charging until the cells cool down to a safe threshold, typically 38°C-40°C.

On a hot summer day with ambient temperatures of 35°C (95°F), waiting for a massive 30,000mAh battery block to passively cool can take 60 to 90 minutes. This downtime kills productivity and forces operators to purchase excessive redundant battery sets just to keep flying. Drone battery spot cooling is the engineering solution to this thermal bottleneck.

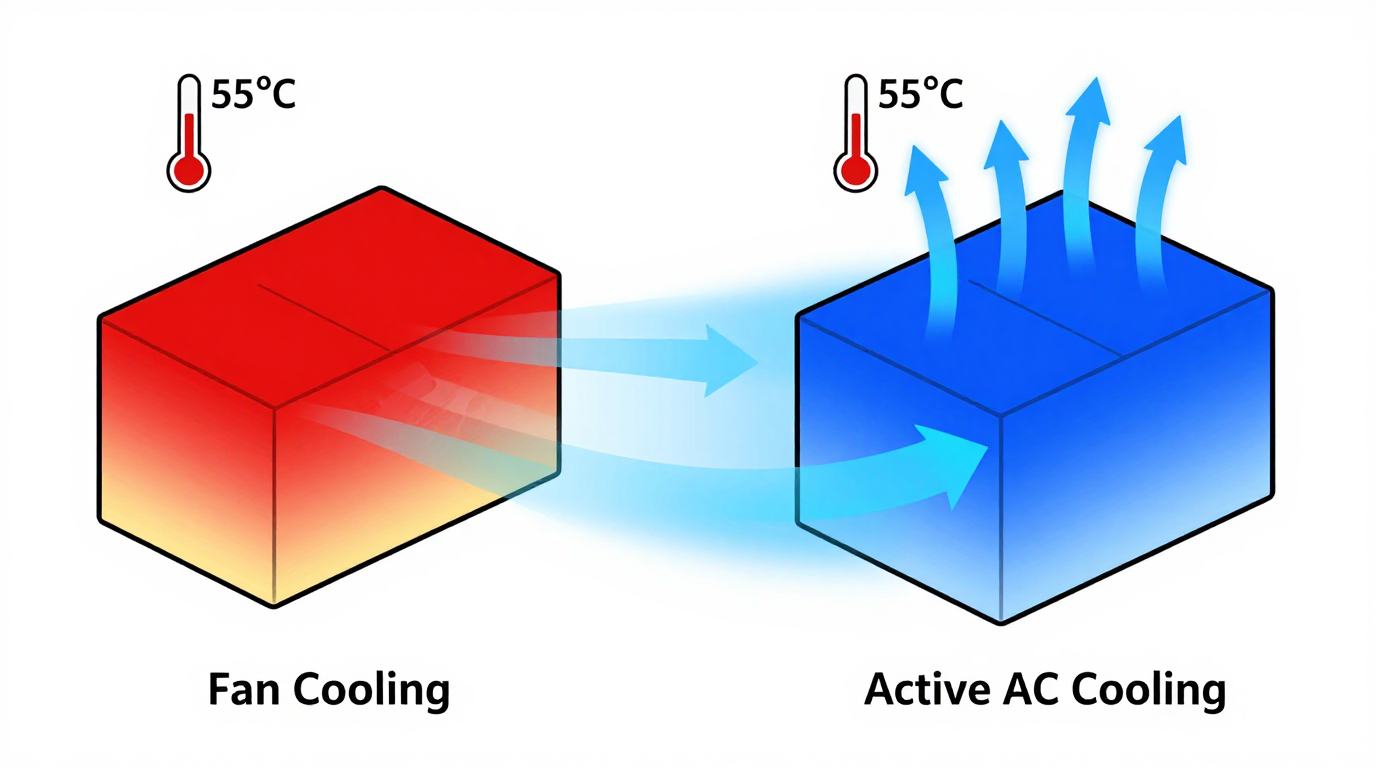

Why Passive Fans Fail: The Physics of Delta T

Many operators attempt to solve this problem with high-velocity fans. While intuitive, this approach is fundamentally limited by thermodynamics. Newton’s Law of Cooling states that the rate of heat loss is proportional to the temperature difference (ΔT) between the object and the cooling medium.

- Scenario A (Fan Cooling): If your battery is 55°C and the ambient air is 35°C, your ΔT is only 20°C. As the battery cools to 45°C, that differential drops to 10°C, and the cooling rate slows crawl. You can never cool the battery below 35°C.

- Scenario B (Active Refrigeration): A RigidChill Portable DC A/C delivers dry, chilled air at 10°C (50°F). Even with the same 55°C battery, your starting ΔT is 45°C—more than double the cooling potential. Crucially, as the battery approaches the charging threshold of 40°C, the AC still maintains a massive 30°C differential, forcing heat out of the core rapidly.

Field tests show that active spot cooling can reduce turnaround time from 60+ minutes to under 20 minutes, effectively matching the cooling time to the charging time.

Operational Case Study: The Crop Spraying Marathon

Let’s look at a real-world scenario from a client operating a fleet of DJI Agras T40 drones in Texas, where summer temperatures regularly hit 38°C (100°F). Their contract required them to spray 1,200 acres in a single day.

The Passive Cooling Failure

Initially, the team relied on ambient air cooling. Each T40 battery provides about 10 minutes of flight time. Charging takes 9-12 minutes with a high-speed generator. However, the cooling time was the killer. Batteries were landing at 58°C and taking over an hour to reach the 40°C charging threshold. The team had 6 sets of batteries ($12,000+ investment), but by 11:00 AM, all sets were hot, and the pilot was grounded for 45 minutes waiting for a “green light.”

The RigidChill Difference

By implementing a RigidChill cooling chamber, they changed the equation. As soon as a battery landed, it was placed in the chilled box. The 10°C air blasted through the battery’s cooling vents.

- Result: The battery cooled to 35°C in just 18 minutes.

- Workflow: By the time the pilot finished flying the next two sets, the first set was cool, charged, and ready.

- Efficiency: They completed the job with zero thermal downtime using only 4 battery sets, reducing their capital equipment load and finishing 3 hours earlier than projected.

The Hardware Advantage: Why RigidChill Fits the Mission

You cannot bring a standard window AC unit to a cornfield or a pipeline inspection site. Commercial drone operations require equipment that is rugged, portable, and power-efficient. Here is why the RigidChill LC Series is the industry standard for ground station cooling:

1. Vibration-Resistant Miniature Compressor

Standard AC units use reciprocating compressors designed to sit still on a concrete pad. If you throw one in the back of a pickup truck and drive down a washboard gravel road, the internal suspension springs will fail, leading to refrigerant leaks. RigidChill units use a Miniature BLDC Rotary Compressor. This design has fewer moving parts and is inherently balanced, making it resistant to the shocks and vibrations of off-road travel.

2. Native DC Power (No Inverter Needed)

Efficiency is key when running off field generators or solar trailers. Converting DC battery power to AC (via an inverter) and then back to DC (inside the air conditioner) wastes 15-20% of your energy as heat. RigidChill units run directly off 24V or 48V DC. This allows you to tap directly into the same large-capacity LiFePO4 battery banks used for field charging, eliminating the need for a separate inverter and increasing your overall runtime.

3. Compact Footprint for Transport

Space in the support vehicle is at a premium. The RigidChill unit is roughly the size of a standard tool box (approx. 18″ x 9″ x 11″). It fits easily on a shelf in a spray trailer or can be tucked into the footwell of a UTV, leaving room for the critical payload and flight batteries.

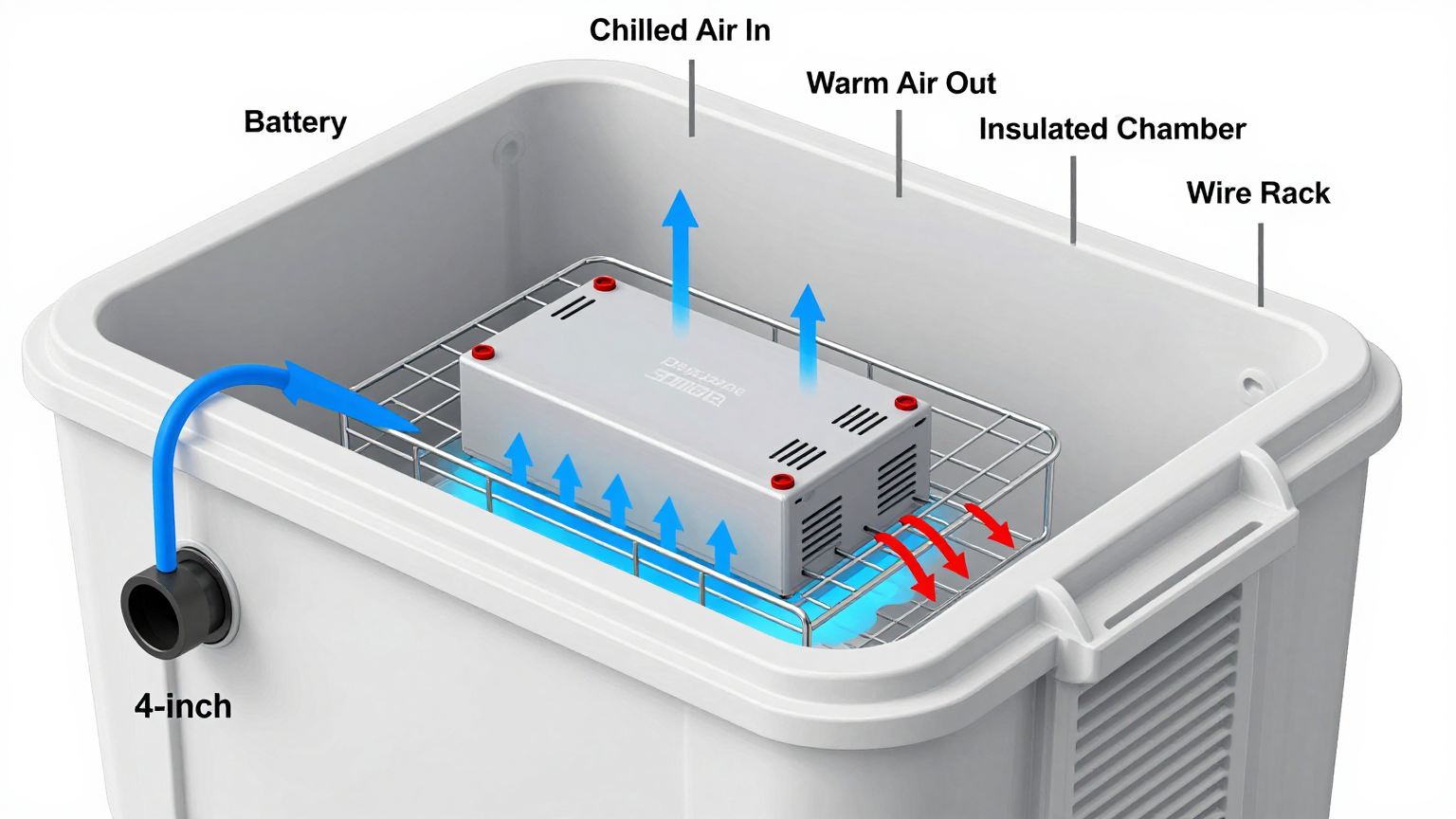

The “Cooling Chamber” Strategy: A DIY Guide

To implement this effectively in the field, you don’t cool the open air; you create a micro-climate. The most efficient setup used by our heavy-lift drone clients involves a modified insulated container (like a Rotomolded cooler) or a custom ducting shroud.

Step-by-Step Build:

- Select Your Box: Use a high-quality cooler (Yeti/Rtic style) or an insulated shipping container. These hold the cold air density much better than a thin plastic tote.

- Port the Intake: Use a 4-inch hole saw to cut a port in the side. Install the RigidChill Flexible Duct Adapter to ensure a sealed connection with the AC unit.

- Create Exhaust/Return: You must allow the warm air to escape, or the box will pressurize and stop airflow. Install a passive louvered vent on the opposite side. Ideally, duct this return air back to the AC intake if possible to create a closed loop, which is even more efficient.

- Install the Rack: Batteries should never sit flat on the floor of the cooler. Use a wire mesh rack or PVC standoffs to elevate the batteries 2 inches. This allows the heavy, cold air to pool underneath and circulate through the bottom vents of the battery casing (where heat often accumulates).

By containing the cold air, you pressurize the box, forcing the chilled air to pass through the ventilation channels of the battery casing rather than just washing over the surface.

Safety Engineering: Thermal Shock vs. Controlled Ramp

A common engineering question we receive is: “Will 10°C air crack the battery casing or shock the cells?” The answer is no, due to the specific heat capacity of the materials involved.

Unlike liquid immersion cooling, which transfers heat almost instantly and can cause mechanical stress if not managed perfectly, air cooling provides a controlled thermal ramp. The plastic or metal outer casing of the battery acts as a thermal buffer. The cold air rapidly cools the casing, which then draws heat from the internal cells via conduction. This gradient is steep enough to be fast, but gentle enough to be safe for the structural integrity of the pack.

Furthermore, cooling the battery actually lowers its internal resistance. A battery charged at a moderate temperature (25°C-35°C) accepts current more efficiently and with less heat generation than one charged at the upper limit of its safety range (40°C), creating a positive feedback loop of efficiency.

Economic Analysis: ROI on Battery Lifecycle

The financial argument for a portable DC air conditioner goes beyond just saving time; it saves the batteries themselves. Lithium chemistry degrades rapidly when exposed to high heat (Calendar Aging). Charging a battery that is warm (even if just below the cutoff) stresses the SEI layer and increases internal resistance.

The Cost of Heat: A set of batteries for a heavy-lift drone can cost over $2,000. If passive cooling forces you to run them hot, you might get 400-500 cycles. By actively quenching them to a stable 25°C-30°C before charging, operators report extending cycle life to 800-1,000 cycles. The AC unit (costing roughly $600-$900) pays for itself by saving just one half of a battery set’s lifespan.

Addressing the Moisture Myth: Dew Point Management

A common concern is condensation. “Won’t cold air make my batteries wet?”

In a properly designed system, the answer is no. Vapor compression air conditioning is inherently dehumidifying. The moisture in the air condenses on the cold evaporator coil inside the AC unit and drips out of the drain hose. The air that exits the nozzle is cold and very dry (low relative humidity).

Safety Protocol: Do not cool the battery below the ambient dew point if you plan to take it out immediately into humid air without use. However, for the purpose of charging, the heat generated during charging will immediately counteract any surface cooling. The goal is to bring the core temp down to the “Green Zone” (20°C-30°C), not to freeze it. As long as the battery remains inside the cooling chamber or is immediately placed on the warm charger, condensation is physically impossible.

Powering the Solution

The RigidChill unit is designed for the energy realities of the field. It runs natively on DC power (12V, 24V, or 48V options available). This means it can be powered directly by:

- The large field generator used for the drone charger (often via a 24V/48V DC output).

- A buffer battery bank (LiFePO4) typically found in solar trailers.

- The 12V/24V auxiliary port of a support vehicle or UTV.

With a power consumption of roughly 100W-250W (depending on mode), the energy cost is negligible compared to the kilowatt-hours being pumped into the flight packs. It is a small energy investment to protect a massive capital asset.

Integration Support

RigidChill provides the thermal engine; you provide the workflow. Whether you are outfitting a spray trailer, a SAR command vehicle, or a film set, our engineering team can help you select the right capacity unit.

Review the LC2810E technical specifications.

0 条评论