Field Snapshot: The rehab sector is a controlled pocket of calm within a chaotic scene. A firefighter, fresh off the line, drops their gear. They’re overheated, physically depleted, and their core body temperature is climbing into a hazardous zone. The clock is ticking. Passive cooling methods—wet towels, shade, oral rehydration—are underway, but they are often too slow to mitigate the risk of heatstroke or to get a valuable team member safely ready for potential redeployment. The core problem is removing a massive amount of stored body heat, quickly and efficiently. This scenario drives the search for a more robust, active thermal management solution.

Key Criteria for a Firefighter Rehab Cooling Protocol Device

Integrating an active cooling system into a firefighter rehabilitation protocol is more than a simple equipment purchase; it’s an operational capability upgrade. Selecting the right firefighter rehab cooling protocol device requires a disciplined evaluation of not just its cooling power, but also its logistical footprint, usability under pressure, and long-term field resilience. For safety managers, operations leads, and procurement teams, the decision hinges on a few fundamental pillars: raw thermal performance, power and deployment logistics, the human interface, and the maintenance burden. A failure in any one of these areas can render an otherwise powerful device ineffective in the field. We’ll break down these decision gates based on our field experience with emergency service crews.

Decoding Cooling Performance: Beyond Simple Temperature Drop

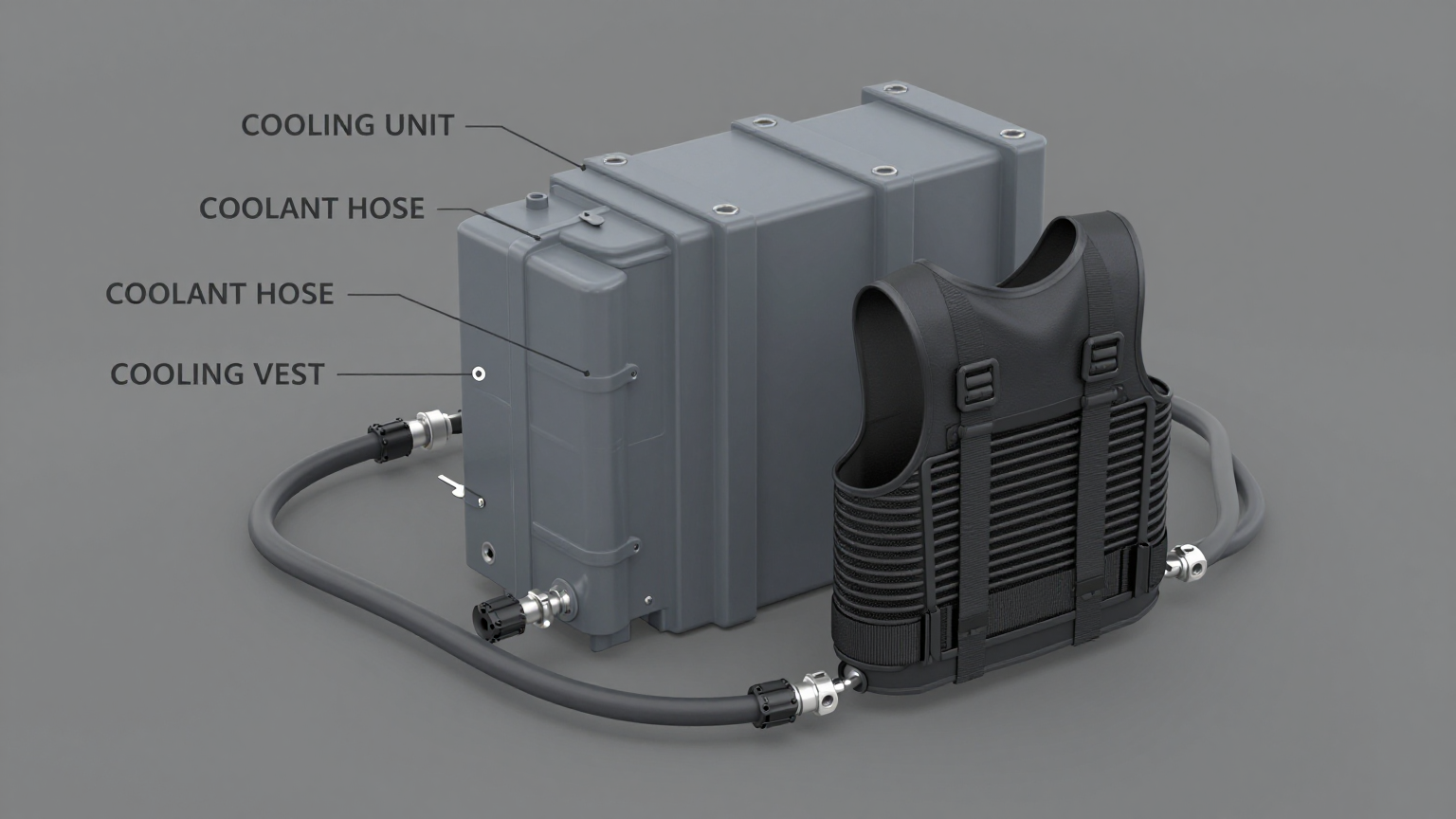

The primary function of an active cooling device is to pull heat out of the body faster than passive methods. This is typically achieved by circulating a chilled liquid through a wearable garment, creating a large surface area for conductive heat transfer. Unlike ice packs, which have an uncontrolled and often dangerously low temperature, a vapor-compression-based liquid chiller provides a consistent and regulated cooling medium.

When evaluating performance specifications, three numbers are critical:

- Cooling Capacity: A capacity of around 1700W (5800 BTU) indicates a significant ability to absorb thermal load. This is the measure of how much heat energy the system can remove from the coolant per unit of time. For context, this is a substantial amount of cooling power directed at a single individual, which is necessary to overcome the metabolic heat generation and stored heat of a firefighter post-exertion.

- Liquid Flow Rate: A flow rate of approximately 12 liters per minute is essential. High flow ensures that the coolant moving through the vest is constantly being replaced with freshly chilled liquid from the reservoir. A low flow rate would mean the liquid heats up too much as it passes through the vest, creating warm spots and reducing the overall effectiveness of the heat transfer.

- Coolant Temperature: The system should be able to maintain a stable coolant temperature, typically around 10°C (50°F). This temperature is low enough for aggressive heat transfer without being so cold as to cause vasoconstriction (the narrowing of blood vessels), which would paradoxically trap heat by reducing blood flow to the skin.

Together, these metrics create a complete picture of a system’s ability to perform its core task. A high-capacity chiller is ineffective without a high flow rate to deliver its cooling potential to the wearer’s torso, where it can be efficiently transferred away from the body’s core.

Power and Logistics: The Unseen Operational Hurdles

A powerful cooling unit is useless if you can’t power it at the scene. This is often the most overlooked aspect during procurement. The primary power source is a critical decision gate. Systems designed for this level of performance typically require AC power (110V/220V), meaning they are intended to be run from a generator or a high-capacity vehicle-mounted inverter. This immediately defines the device as a stationary, rehab-zone asset, not a man-portable cooling solution.

The next number to scrutinize is power consumption. A unit with a 700W power draw is a significant electrical load. When planning your power budget, you must account for this. For example, a standard 2kW portable generator could theoretically run two such units, but you must also factor in the power needs of lighting, communications, and other rehab equipment. A dedicated power plan is not optional.

Physical logistics are equally important. Consider the unit’s dimensions (e.g., 550 x 260 x 350 mm) and weight (around 28 kg or 62 lbs). This is not a lightweight piece of kit. It requires dedicated space on a vehicle and must be manageable for personnel to lift and position. Questions to ask include:

- Where does this live on the truck?

- Who is responsible for deploying and stowing it?

- How does its weight and bulk impact vehicle payload and organization?

Finally, the umbilical or hose length, often around 3 meters (10 feet), defines the operational bubble around the base unit. This length must be sufficient to allow the firefighter some movement and comfortable positioning without creating a trip hazard in an already busy area.

The Human Factor: Wearability and Protocol Integration

The most sophisticated cooling engine is irrelevant if the wearable component is cumbersome or difficult to use. The cooling suit vest is the critical interface between the technology and the firefighter. The material is a key consideration; it should be a breathable, and ideally flame-retardant, fabric that can be worn comfortably against the skin or a thin base layer. Adjustable straps are crucial for ensuring a snug fit on various body types, as good surface contact is paramount for effective thermal conduction.

The connectors are another vital detail. Field-proven systems use dry-break quick-disconnects. These allow for rapid, one-handed connection and disconnection without spilling coolant. In a rehab situation where every second counts and personnel are fatigued, fumbling with screw-on or leaky connectors is an unacceptable operational drag. This feature allows one firefighter to disconnect and move on while another immediately connects to the same unit, maximizing throughput.

Integrating the device into your rehab protocol requires thinking through the entire process. How long does it take for a firefighter to get into the vest? How intuitive is the connection process for a user who is exhausted and under stress? The goal is to make using the device a seamless, simple step in the existing flow of rehab, not a complex new procedure that requires extensive training or fine motor skills.

Maintenance and Field Durability Considerations

Emergency scenes are harsh environments. Any equipment deployed must be built to withstand rough handling, dirt, and moisture. The outer casing of the cooling unit should be robust, and its components, especially connectors and hoses, must be field-serviceable or easily replaceable. The use of a standard refrigerant like R134a simplifies potential service down the line, as it is widely available and understood by HVAC technicians.

The coolant itself is another practical consideration. Systems that use a simple water or water-glycol mix are far easier to manage in the field than those requiring proprietary or hard-to-source fluids. Topping off the reservoir should be a straightforward task.

A critical, and often unasked, question for procurement is the decontamination and cleaning protocol for the vests. These garments will be saturated with sweat and exposed to environmental contaminants. Is the vest machine washable? Does it require special cleaning agents? Having a clear and sustainable cleaning process is essential for hygiene and to ensure the long-term usability of the system. A stock of multiple vests per cooling unit is a common practice to allow for rotation and cleaning cycles.

Common Failure Modes and On-Scene Triage

Even the most reliable equipment can encounter issues in the field. Understanding potential failure modes allows for rapid triage.

| Symptom | Immediate Checks | Potential Interpretation |

|---|---|---|

| Insufficient Cooling | Check coolant level in reservoir. Inspect hoses for kinks or blockages. Verify generator is not overloaded. | Low coolant or obstructed flow are the most common causes. A strained generator may also provide unstable voltage, reducing performance. |

| Unit Fails to Start | Confirm power cord is securely connected at both ends. Check circuit breaker on the generator/inverter. Test with another device to confirm power source is active. | Power delivery is the first point of failure. Always confirm the power source is stable and functioning before assuming a fault with the unit itself. |

| Leaks at Connectors | Disconnect and reconnect, ensuring a firm ‘click’. Visually inspect O-rings or seals inside the connectors for debris or damage. | Improper connection is common. If reseating doesn’t solve it, the connector’s internal seal may be compromised, which is a high-wear component. |

Frequently Asked Questions (FAQ)

1. How many firefighters can one unit cool at a time?

Typically, these systems are designed for a 1:1 ratio, with one cooling unit supporting one vest at a time to ensure maximum thermal transfer. Protocols can be designed to cycle multiple firefighters through a single unit sequentially.

2. Can it run from a standard 12V vehicle battery?

Not directly. A system requiring 700W of AC power would need a heavy-duty DC-to-AC inverter (typically rated 1500W or higher to handle startup surges) and a robust vehicle electrical system or dedicated battery bank to support the load without draining the primary starting battery.

3. What is the typical maintenance schedule?

This is manufacturer-dependent, but common practice includes pre- and post-operation checks of coolant levels and hose integrity, along with periodic cleaning of any air intake filters. A more thorough annual service is also a good protocol.

4. Is the cooling vest a one-size-fits-all solution?

Most are designed as ‘one-size-fits-most,’ utilizing adjustable straps on the shoulders and sides to accommodate a wide range of body types. Ensuring a snug fit is key to performance.

5. Can we use third-party vests with the cooling unit?

This is generally not recommended. The flow rate, pressure, and connector type are often proprietary to a specific system. Mismatching components can lead to poor performance, leaks, or damage to the pump.

6. What is the operational noise level?

As these units contain a compressor and fans, they will produce noise similar to a window air conditioner. This should be considered when positioning the unit in the rehab zone to ensure it doesn’t interfere with medical monitoring or communication.

Integration Support

The transition from passive to active cooling involves aligning the equipment’s capabilities with your department’s specific operational constraints. If your deployment scenarios involve different power availability or logistical challenges, we can review your requirements to help define a viable integration path. The key is ensuring the hardware matches the realities of your rehab protocols.

Conclusion: A System, Not Just a Box

Choosing a firefighter rehab cooling device is a decision that rests on a foundation of logistical and operational reality. While the cooling capacity is the headline feature, the long-term success of the program depends on the less glamorous details: the power budget, the ease of use for an exhausted operator, and the durability to survive repeated deployments. By evaluating these systems through the lens of a complete operational cycle—from truck storage to on-scene deployment, user interaction, and post-incident maintenance—you can select a solution that becomes a reliable and effective tool in the critical mission of managing firefighter heat stress.

0 条评论