We arrived on-site to inspect a remote telecom cabinet that kept tripping thermal alerts, especially after a recent coastal storm. The enclosure was located in a region known for salt fog and high humidity. From the outside, the issue seemed obvious: the air filter was caked with a crust of salt and dust, completely choking off airflow. But replacing the filter was only a temporary fix; the deeper problem was the cooling strategy itself. This kind of recurring failure in harsh environments is a clear signal that the initial design assumptions were wrong.

This field note walks through our diagnostic process for this exact scenario. By the end, you’ll have a clear framework for identifying why conventional cooling fails in these conditions and what decision gates lead to a more robust, long-term solution.

Field Snapshot: Diagnosing Overheating in a Telecom Cabinet Cooling in Salt Fog Environment

The immediate problem was a clogged filter, but the real issue was the design choice to use an open-loop, fan-and-filter system in a corrosive environment. Every time the fan runs, it pulls in salt-laden, humid air. The salt clogs the filter, and what gets through attacks the electronics inside. This approach creates a cycle of reactive maintenance, equipment degradation, and eventual failure. Our goal was to determine the point at which the operational cost and risk of failure made this approach untenable, forcing a move to a closed-loop architecture.

First Checks: What We Look for On-Site

When we encounter a thermally unstable enclosure in the field, we start with a few basic checks to establish a baseline and understand the failure cascade.

- Check: Air Filter Condition & Airflow Rate.

Why: This is the most common and obvious point of failure in a filtered system. A clogged filter is the first sign of restricted airflow.

What it suggests: If the filter is heavily clogged, it confirms that airflow restriction is the immediate cause of overheating. However, the more important question is the rate at which it clogs. If it requires monthly replacement, the cooling strategy is not sustainable. - Check: Internal Dust & Corrosion.

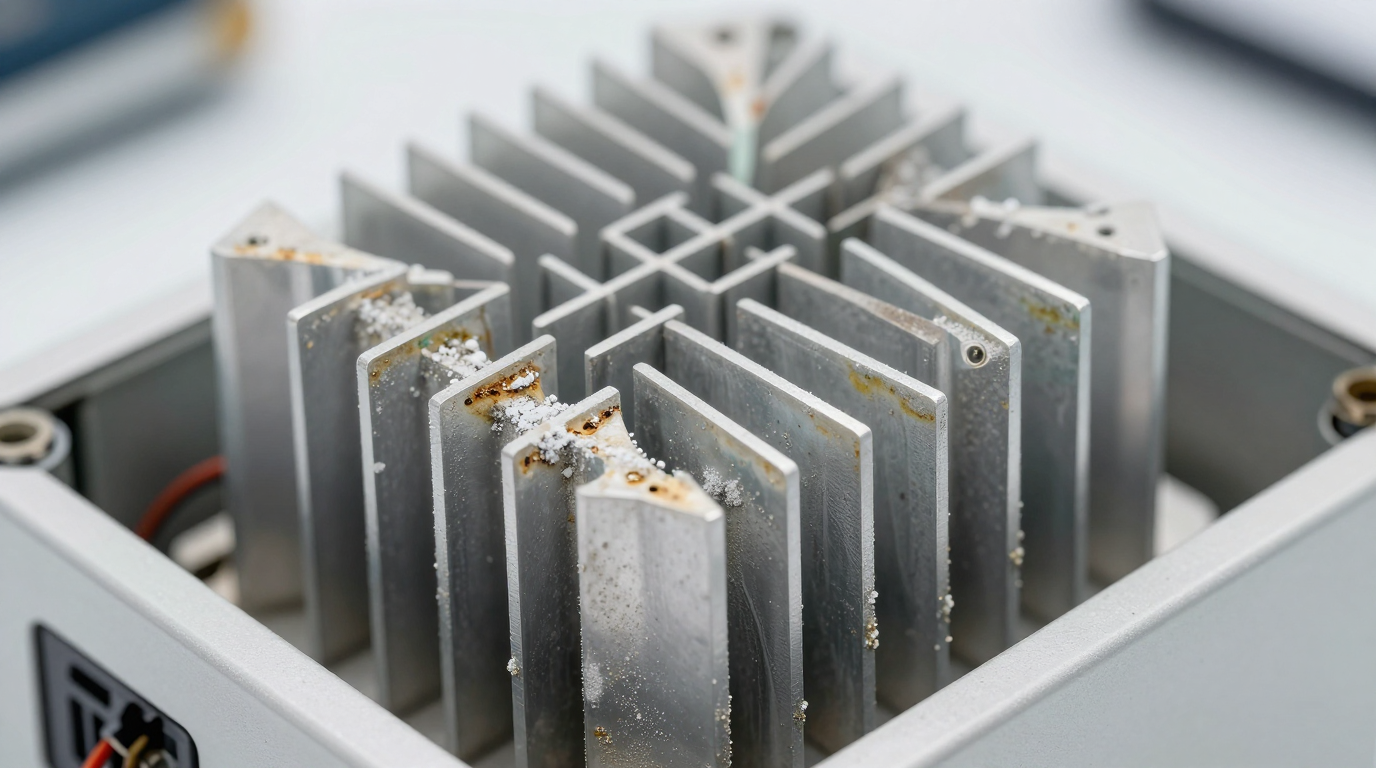

Why: We open the cabinet to inspect for any contaminant ingress past the filter. We look for a fine layer of dust on horizontal surfaces and signs of white or green corrosion on heatsinks, connectors, and PCB traces.

What it suggests: Any contamination inside the enclosure means the open-loop system has failed in its primary mission. It proves that corrosive elements are being actively pulled across the very components the system is meant to protect. - Check: Temperature Logs vs. Ambient Conditions.

Why: We analyze historical data from the cabinet’s internal sensors and correlate it with local weather data, looking for performance dips after rain, fog, or high humidity events.

What it suggests: If the internal temperature spikes dramatically when humidity is high, it confirms that the airborne salt is absorbing moisture and becoming far more corrosive and effective at fouling the system. This proves the environment itself is the core problem.

Failure Modes & Constraints in Corrosive Environments

In a salt fog environment, overheating is often just the final symptom of a series of underlying failures. Understanding these modes is key to justifying a change in cooling architecture.

- Symptom: Rapidly Clogging Filters.

Likely Cause: High concentration of airborne salt crystals and dust.

Why it matters: This leads to unsustainable maintenance cycles. The operational cost of frequent, remote site visits (truck rolls) can quickly exceed the initial cost of the cooling hardware. - Symptom: Overheating with a Clean Filter.

Likely Cause: Micro-corrosion on heatsink fins.

Why it matters: Salt air creates an insulating oxide layer on the aluminum fins, dramatically reducing their thermal conductivity. The heatsink becomes less and less effective over time, even if the airflow is strong. - Symptom: Intermittent Fan Failure.

Likely Cause: Corrosion of the fan motor’s bearings and electrical contacts.

Why it matters: Unreliable airflow leads to unpredictable thermal throttling and shortens the lifespan of the electronics that rely on it. - Symptom: Gradual Decline in System Performance.

Likely Cause: A fine layer of conductive, salt-based dust settling on PCBs.

Why it matters: This film can impede heat dissipation from surface-mount components and, when combined with humidity, create pathways for electrical shorts. - Symptom: Brittle or Cracked Enclosure Gaskets.

Likely Cause: UV exposure and constant temperature cycling.

Why it matters: A compromised seal renders any IP or NEMA rating meaningless. Contaminated air will bypass the filter entirely, flowing through the path of least resistance. - Symptom: System Fails During Humid or Foggy Weather.

Likely Cause: Salt is hygroscopic, meaning it absorbs water from the air.

Why it matters: This moisture turns the salt dust into a conductive, corrosive electrolyte, accelerating damage. The cooling system is actively importing the agent of its own destruction.

Decision Gates: When to Move to Closed-Loop Cooling

Based on the initial checks and failure modes, we establish clear decision gates. Crossing any of these thresholds makes it impractical to continue with a conventional fan-and-filter system.

Gate 1: Maintenance Cadence & Cost

- Constraint: The site is remote, unmanned, or part of a large network where service visits are expensive.

- Decision Trigger: If the filter cleaning/replacement interval is less than six months to maintain thermal stability.

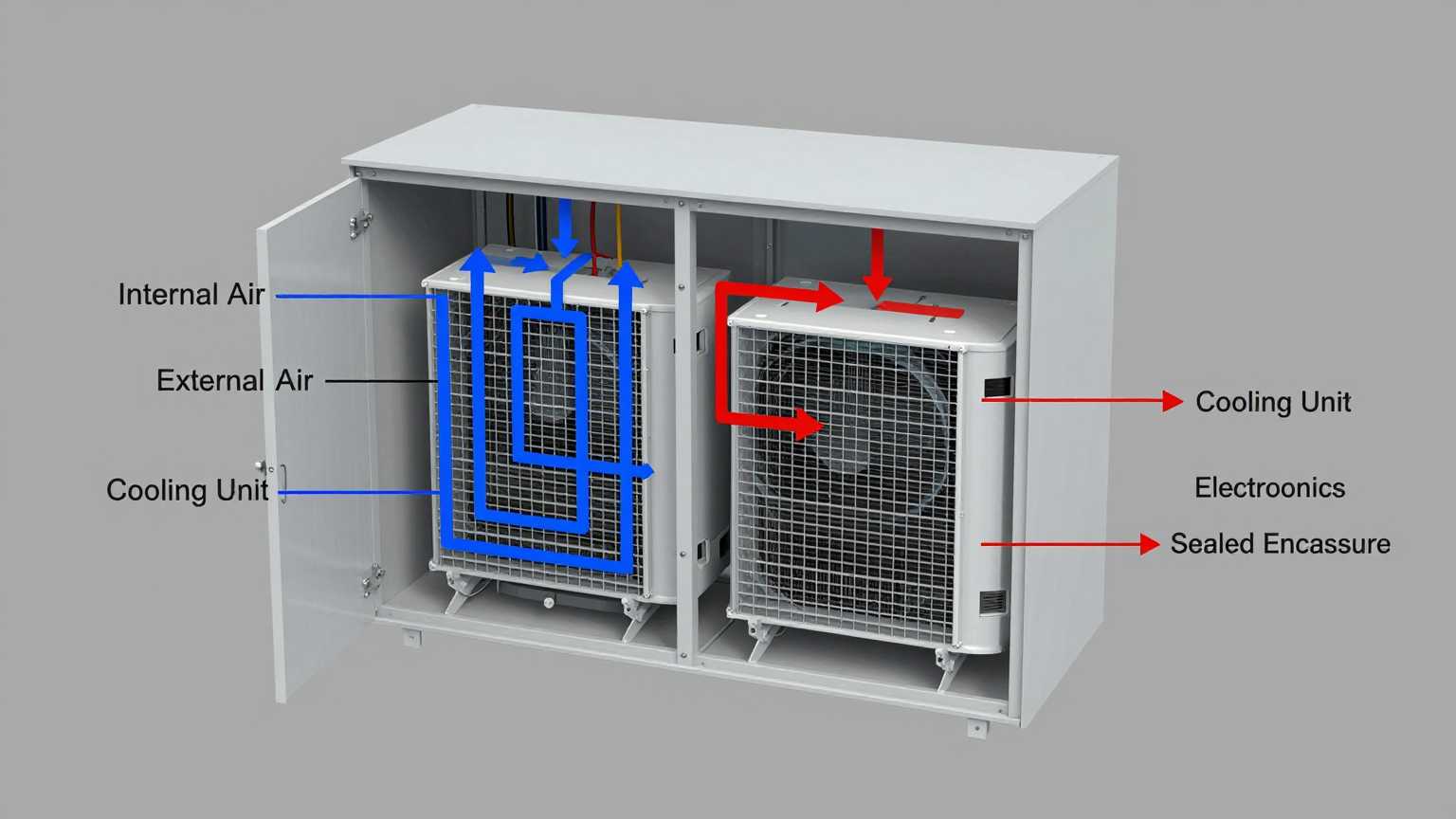

- Engineering Resolution: Implement a cooling system that does not depend on filtering ambient air. A closed-loop system isolates the internal air from the external environment.

- Integration Trade-off: This requires a higher upfront capital investment in the cooling unit but drastically reduces the long-term operational expense and risk of downtime.

Gate 2: Environmental Severity

- Constraint: The environment contains known corrosive agents (salt fog) or abrasive particulates (sand, industrial dust).

- Decision Trigger: Any visual evidence of corrosion or dust inside the enclosure. This is a clear sign that the open-loop approach is not protecting the equipment.

- Engineering Resolution: Isolate the internal and external air paths completely. This is the central challenge of a telecom cabinet cooling in salt fog environment.

- Integration Trade-off: This resolution is only effective if the enclosure itself is properly sealed (e.g., IP55 or higher). Gasket integrity, door latch pressure, and cable gland sealing become critical design parameters.

Gate 3: Thermal Stability Requirements

- Constraint: The internal electronics have a narrow operating temperature range or must be kept below the peak ambient temperature.

- Decision Trigger: When monitoring shows that a fan-based system cannot hold the target temperature during peak solar load or on hot days.

- Engineering Resolution: Move from simple air exchange to active refrigeration. A vapor-compression system can create a significant temperature differential (ΔT) and maintain a stable internal setpoint regardless of most ambient swings.

- Integration Trade-off: An active system introduces a compressor and refrigerant (like R134a). It requires a reliable DC power source (typically 24V or 48V DC) that can handle the compressor’s load. While more complex than a fan, it provides precise, predictable cooling.

Integration Notes for Miniature DC Compressor Systems

When upgrading to a closed-loop, active system, the integration details are critical for success. This is not a simple fan swap.

- Mechanical: The system must be mounted securely to handle the compressor’s minor vibration. Plan for condensate management; as the internal air is cooled, moisture will condense and must be drained away from the electronics. Ensure all enclosure penetrations are sealed to maintain the IP rating.

- Electrical: These systems are designed for common DC voltages in telecom and other industries (e.g., 24V, 48V DC). The power supply circuit must be sized to accommodate both the steady-state current and the brief inrush current when the compressor starts. Use appropriately gauged wire and corrosion-resistant connectors.

- Thermal: The core principle is the separation of air. The internal loop circulates and cools the air inside the cabinet. The external loop draws ambient air across the condenser coils to expel the collected heat. There must be no leakage between these two loops for the system to work efficiently.

- Maintenance: The maintenance model shifts from frequent, reactive filter replacement to infrequent, proactive inspection. The new schedule involves checking door gaskets, cleaning the external condenser coils, and verifying the condensate drain is clear. This is a far more predictable and less burdensome service plan.

FAQ: Common Objections and Field Questions

During design reviews, engineers often raise the following points.

- Isn’t a bigger fan and a better filter enough for a telecom cabinet cooling in salt fog environment?

Typically, no. This approach only treats the symptom (clogging), not the root cause (corrosive air). A better filter may clog just as fast, and a bigger fan will pull even more contaminated air into the system, potentially accelerating corrosion. - Why not use a thermoelectric (Peltier) cooler?

Thermoelectric coolers can be a fit for very small heat loads, but they become inefficient (low COP) as the heat load increases. For loads in the 100W to 550W range, a vapor-compression system is often more effective, especially in high ambient temperatures. - Does this require a completely new, custom enclosure?

Not always. Many standard NEMA or IP-rated enclosures can be retrofitted. The key is to verify the integrity of the seals. An IP55 rating is a good starting point, as it protects against dust and water jets, indicating a tight seal. - What is the power draw of a DC compressor system?

It’s dependent on the heat load, but miniature compressor systems are specifically designed for DC-powered environments (like 48V DC telecom racks) and are significantly more efficient at removing heat than thermoelectric alternatives. - How does this handle peak solar load on a hot day?

This is a key advantage of active refrigeration. Unlike a heat exchanger, which loses effectiveness as the ambient temperature approaches the desired internal temperature, a compressor-based system can actively pump heat out and maintain a cool, stable interior even when it’s hot outside. - Our current fan is salt-spray rated. Isn’t that enough?

A component-level rating is good, but it doesn’t guarantee system-level reliability. A salt-spray-rated fan that pulls corrosive salt air across an untreated heatsink and non-rated electronics will still result in a system-level failure. The entire chain of components is at risk.

Conclusion: Shifting from Reactive Filtering to Proactive Isolation

For electronics deployed in coastal, industrial, or dusty locations, relying on a fan-and-filter cooling system is an operational liability. The low initial cost is quickly offset by high maintenance expenses, poor reliability, and the risk of catastrophic equipment failure. The core problem is the constant introduction of environmental contaminants.

The engineering solution is to move from filtering to isolation. A closed-loop, active cooling system creates a clean, controlled internal environment, protected from the harsh external world. This approach is a fit for any critical application where reliability is paramount and on-site maintenance is expensive or impractical. For deployments in clean, climate-controlled indoor spaces, it may be overkill. But for a challenging telecom cabinet cooling in salt fog environment, it is often the most reliable and cost-effective long-term solution. For applications requiring this level of robust, closed-loop cooling, reviewing the specifications of a miniature DC compressor is a logical next step.

0 条评论