High Humidity Charger Cabinets: Engineering a Micro AC for High Humidity Enclosure Protection

For reliability engineers designing outdoor power electronics, heat is often the primary enemy. Thermal throttling reduces charging speeds in EV infrastructure, and overheating components lead to premature failure in telecom radios. However, in many deployment environments—from the humid subtropics to coastal industrial zones—moisture is the more insidious threat. While heat degrades components over time, moisture can cause immediate, catastrophic dielectric breakdown.

The challenge is compounded when these systems operate off-grid or in mobile applications where power budgets are tight. Traditional large-scale enclosure cooling is often too bulky or power-hungry for compact DC-powered cabinets. This creates a specific engineering gap: the need for a micro ac for high humidity enclosure applications that provides both thermal management and active dehumidification without dominating the energy budget.

This article analyzes the engineering constraints of deploying sensitive electronics in high-humidity environments. We will evaluate cooling architectures, examine the physics of moisture-driven failure, and provide a decision framework for selecting thermal management systems that mitigate condensation risks in sealed cabinets.

Deployment Context: The Moisture Burden

To understand the necessity of active cooling in humid environments, we must look at the specific stresses placed on outdoor enclosures. Unlike controlled data centers, outdoor cabinets face diurnal temperature cycles that create pressure differentials, effectively “breathing” in moist air if sealing is imperfect.

Scenario A: The Coastal EV Charger

Consider a Level 2 or DC fast charger deployed in a coastal region. The ambient air is laden with salt spray and maintains a relative humidity (RH) above 80% for long periods.

Constraints:

- Corrosion Risk: Salt fog accelerates galvanic corrosion on any exposed connector.

- Thermal Load: High utilization rates generate significant internal heat, requiring rejection to an ambient environment that may already be 35°C (95°F) or higher.

- Failure Mode: If the cabinet uses open-loop cooling (fans), salt and moisture are pulled directly over the PCB. If sealed but uncooled, internal temperatures spike. If sealed and cooled by a passive heat exchanger, the internal surface temperature may drop below the dew point during cool-down cycles, forming internal rain.

Scenario B: The Tropical Remote Monitoring Station

A solar-powered sensor array in a tropical rainforest environment.

Constraints:

- Ambient Conditions: Consistently high humidity (near 100% at night) with ambient temperatures ranging from 25°C to 40°C.

- Power Budget: Limited by battery capacity and solar array size. The cooling solution cannot draw excessive current, especially during nights or cloudy days.

- Maintenance: Remote access is difficult; truck rolls are expensive. Filter changes for fan-based systems are logistically impractical.

Decision Matrix: Selecting the Right Thermal Architecture

When moisture is a primary constraint, the selection of thermal management technology shifts from simple heat rejection to environmental isolation and humidity control. The table below compares common approaches for compact DC cabinets.

| Technology | Loop Type | Sub-Ambient Cooling? | Active Dehumidification? | High Humidity Suitability | Power Efficiency (COP) |

|---|---|---|---|---|---|

| Filter Fans | Open | No | No (Imports Moisture) | Poor (High risk of ingress/corrosion) | High (Low draw, but low protection) |

| Air-to-Air Heat Exchanger | Closed | No | No | Moderate (Sealed, but cannot cool below ambient) | Moderate |

| Thermoelectric (Peltier) | Closed | Yes | Yes (Inefficient) | Low-Moderate (Struggles with high latent loads) | Low (typically COP < 0.6) |

| Micro DC Aircon (Compressor) | Closed | Yes | Yes (High Capacity) | High (Active moisture removal + sealing) | High (typically COP > 2.0) |

Implication: For deployments where ambient humidity is high and electronics must be isolated from the outside air, open-loop systems are typically disqualified. Among closed-loop options, only compressor-based systems (like a Micro DC Aircon) offer the combination of high efficiency and the capacity to handle both sensible heat loads and the latent load of dehumidification.

Quick Selection Rules for Engineers

Use these heuristics during the design review phase to determine if a compressor-based solution is required:

- Rule 1: If Tambient ≥ Tinternal_target, you cannot use fans or passive heat exchangers; active refrigeration is required.

- Rule 2: If the deployment site has sustained RH > 60% and the electronics contain exposed high-voltage traces, an open-loop system presents an unacceptable corrosion risk.

- Rule 3: If the power source is DC (battery/solar) and the heat load exceeds 100W, a Micro DC Aircon typically offers a better ROI on power consumption than Thermoelectric (TEC) coolers due to higher Coefficient of Performance (COP).

- Rule 4: If the enclosure requires NEMA 4/4X (or IP65+) ratings, the cooling system must be closed-loop.

- Rule 5: If the equipment undergoes rapid thermal cycling (e.g., intermittent high-power charging), active humidity control is often needed to prevent condensation during the cool-down phase.

Failure Modes: The Unseen Enemies of Uptime

In high-humidity environments, thermal management is not just about keeping components cool; it is about keeping them dry. Failure to manage moisture leads to specific, often irreversible damage mechanisms.

Electrochemical Migration (ECM) and Dendrites

When moisture forms a conductive film across a PCB, dissolved metal ions can migrate between traces under a DC bias. This leads to the growth of metallic filaments, or dendrites, which eventually bridge the gap and cause a short circuit. This is particularly prevalent in miniaturized power electronics with tight pitch spacing.

Hygroscopic Swelling and Delamination

Certain PCB substrates and potting compounds can absorb moisture from the air. This hygroscopic swelling induces mechanical stress, which can lead to delamination of board layers or cracking of solder joints, especially when combined with thermal cycling.

Dielectric Breakdown

High humidity reduces the dielectric strength of air and insulating materials. In high-voltage DC applications (like EV chargers), this increases the risk of arcing or flashover, potentially destroying the equipment and posing a safety hazard.

Engineering Fundamentals: Vapor Compression vs. Humidity

Why is a compressor-based system superior for these scenarios? It comes down to the physics of phase change and the psychrometric chart.

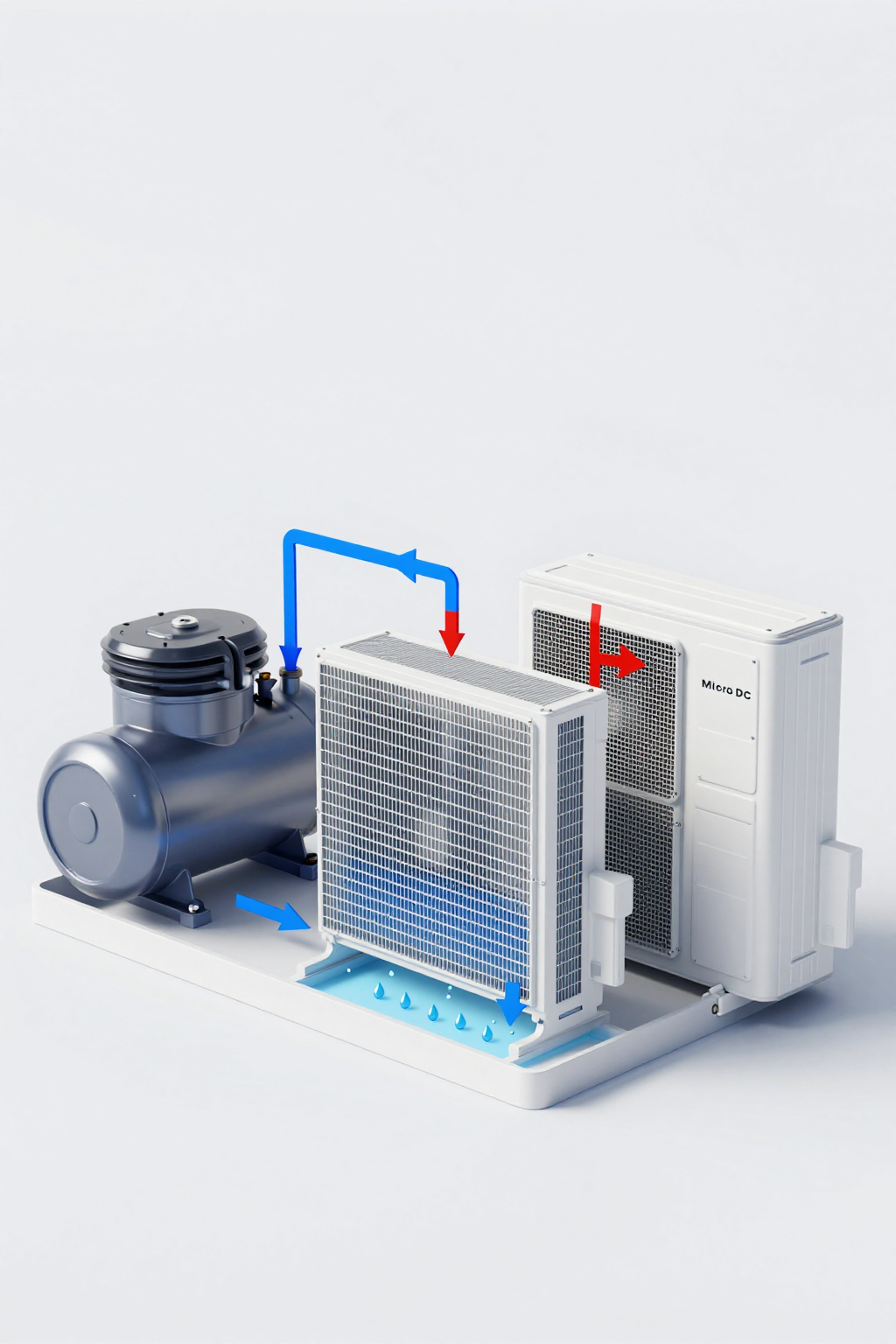

The Dehumidification Mechanism

A vapor-compression cycle (the core of a Micro DC Aircon) creates a cold surface at the evaporator coil. As warm, moist air from inside the cabinet passes over this coil, its temperature drops below the dew point. Water vapor condenses into liquid on the coil fins and is collected in a drain pan. This process actively removes water mass from the internal air volume, lowering the internal relative humidity.

In contrast, a fan simply moves air. If the outside air is humid, the fan ensures the inside air is equally humid. A heat exchanger keeps the air separate but does not actively remove moisture; if the internal walls cool down faster than the air inside, condensation forms on the walls or components rather than on a controlled drainage surface.

Delta T and Heat Rejection

The “Delta T” refers to the temperature difference between the ambient air and the target internal temperature. Passive systems rely on a large Delta T to move heat (i.e., the inside must be much hotter than the outside). Active refrigeration systems create their own artificial Delta T via the refrigerant cycle, allowing them to reject heat even when the outside air is hotter than the inside cabinet. This “temperature headroom” is critical in tropical or desert climates where ambient temperatures can soar.

Performance Data & Verified Specs

For engineers sizing a solution, specific parameters are necessary. The Arctic-tek Micro DC Aircon series utilizes miniature DC compressors to provide significant cooling density in a small footprint. These units are designed for direct integration into 12V, 24V, and 48V DC systems, eliminating the need for inefficient AC inverters.

The following specifications apply to the DV Series (Pro versions), which are frequently utilized in sealed outdoor enclosures:

| Model | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a | BLDC Inverter Rotary |

| DV1920E-AC (Pro) | 24V | 450W | R134a | BLDC Inverter Rotary |

| DV1930E-AC (Pro) | 48V | 450W | R134a | BLDC Inverter Rotary |

| DV3220E-AC (Pro) | 24V | 550W | R134a | BLDC Inverter Rotary |

These units feature variable-speed blower and inverter control, allowing the system to ramp up during peak heat loads and ramp down to conserve power during steady-state operation. The use of R134a (and options for R290/R1234yf in specific series) ensures compliance with global refrigerant standards.

For custom integrations requiring component-level cooling, the Miniature DC Compressor series (such as the QX1902VDL or QX3202VDL) allows integrators to build custom thermal loops directly into the chassis of the electronics.

Field Implementation Checklist

Selecting the right micro ac for high humidity enclosure protection is only half the battle. Proper integration is required to ensure the system performs as intended.

Mechanical Integration

- Condensate Management: The active dehumidification process produces water. You must route a drain tube from the AC unit to the exterior of the cabinet. Ensure the drain line has a trap or a one-way valve to prevent insects or dust from entering.

- Gasket Integrity: Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality. Ensure the mounting flange of the AC unit is sealed with appropriate closed-cell foam or IP-rated gaskets.

- Airflow Short-Cycling: Ensure the cold air discharge is not immediately sucked back into the return intake. Use ducting or baffles if necessary to force cold air to the bottom of the cabinet (or hot spots) and pull warm air from the top.

Electrical & Control

- Voltage Drop: DC compressors can draw significant inrush current (though soft-start features in the driver board mitigate this). Ensure cabling from the battery/bus is sized correctly to prevent voltage droop that could trigger under-voltage faults.

- Hysteresis Settings: Configure the controller hysteresis to prevent rapid cycling of the compressor, which reduces lifespan. A deadband of 2-4°C is often recommended.

Expert Field FAQ

Q: Can I just use a heater to prevent condensation?

A: Heaters can prevent condensation by keeping internal temperatures above the dew point, but they add to the thermal load when the equipment is running. In hot climates, adding heat to sensitive electronics is often counterproductive. A Micro DC Aircon removes moisture while cooling, solving both problems simultaneously.

Q: How does a micro ac for high humidity enclosure impact the IP rating?

A: A properly installed closed-loop AC unit maintains the enclosure’s IP rating (e.g., IP55 or IP65). The external loop of the AC is sealed from the internal loop. However, the cutout in the cabinet door must be perfectly sealed.

Q: What is the maintenance interval for these units?

A: Unlike fan-based systems that require frequent filter changes in dusty environments, the internal loop of a Micro DC Aircon is sealed and maintenance-free. The external condenser coil may need occasional cleaning (compressed air) depending on dust levels, but many designs are filter-less to minimize maintenance.

Q: How much power does the DV1920E-AC draw?

A: Power draw varies by load. At nominal capacity (450W cooling), the coefficient of performance (COP) is typically high, meaning the electrical draw is significantly less than the cooling provided. Exact current draw depends on the specific operating point (ambient vs. internal temp).

Q: Can these units handle corrosive salt spray?

A: Standard units are robust, but for direct coastal exposure, check if the condenser coil has a protective coating (like epoxy or gold-fin) or if the housing is stainless steel. The internal components are protected by the closed loop.

Q: Is soft-start included?

A: Yes, the integrated driver board (PCB) for the BLDC inverter rotary compressor typically includes soft-start logic to minimize inrush current, which is critical for battery-powered applications.

Conclusion & System Logic

The decision to implement active cooling in outdoor cabinets is rarely driven by temperature alone. In many deployments, the “silent killer” is humidity. While fans are cheap and simple, they are often disqualified in harsh environments due to their inability to seal the cabinet or remove moisture. Thermoelectric coolers offer sealing but often lack the efficiency and capacity for substantial heat loads.

For power electronics, EV chargers, and telecom systems operating in humid, off-grid, or mobile environments, the Micro DC Aircon represents a balanced solution. It provides the high cooling capacity of a vapor-compression system with the efficiency and compact form factor required for DC-powered applications. By actively condensing moisture out of the internal air, it protects critical components from corrosion and short circuits, ensuring long-term reliability where other methods fail.

Request Sizing Assistance

Proper sizing is critical to balance cooling capacity with power consumption. To receive a technical recommendation for your specific enclosure, please prepare the following inputs and contact our engineering team:

- Ambient Conditions: Max Temperature (°C) and Solar Loading exposure.

- Target Internal Temperature: Max allowable component temperature.

- Heat Load Estimate: Total dissipation (Watts) of internal electronics.

- Power Source: Available Voltage (12V/24V/48V) and Current limits.

- Sealing Requirement: Target IP or NEMA rating.

- Dimensions: Cabinet size and available mounting space.

0 条评论