Preventing Throttling in Sealed Telecom Cabinets: A Guide to Active Cooling Integration

As telecom infrastructure migrates closer to the edge, the engineering constraints for outdoor cabinets have shifted. High-density compute nodes, 5G radio equipment, and fiber-to-the-home (FTTH) distribution units are increasingly deployed in environments that lack climate control. For OEM engineers and system integrators, the challenge is no longer just about protecting electronics from rain or dust; it is about managing thermal loads in sealed enclosures where passive dissipation is insufficient.

In many deployments, the ambient air temperature combined with solar loading exceeds the maximum operating temperature of the internal components. When the temperature inside a cabinet rises above the safe threshold for lithium-ion batteries or sensitive processors, systems throttle performance or shut down completely to prevent permanent damage. This thermal throttling results in network latency and service interruptions that are unacceptable for critical infrastructure.

Traditional cooling methods like filtered fans introduce contaminants, while air-to-air heat exchangers depend heavily on a significant temperature differential (Delta T) between the inside and outside air. For harsh environments requiring NEMA 4 or IP65-level protection, a micro ac for telecom cabinet integration is often the often the most practical method to maintain sub-ambient temperatures without compromising the seal. This article outlines the engineering logic, selection criteria, and integration best practices for deploying active DC cooling in remote, off-grid, or outdoor telecom applications.

Deployment Context: The Reality of Edge Heat

To understand the necessity of active cooling, we must look at specific deployment scenarios where passive or fan-based cooling typically fails. These scenarios share common constraints: high internal heat density, strict sealing requirements, and elevated ambient temperatures.

Scenario A: The Desert Repeater Station

Consider a solar-powered repeater station located in an arid region. The ambient air temperature can reach 45°C (113°F) or higher. Direct solar loading on the cabinet surface adds a significant thermal burden, potentially raising the internal skin temperature well above ambient. The internal equipment—routers, switches, and backup batteries—generates a constant heat load (e.g., 300W to 500W).

In this context, an air-to-air heat exchanger cannot cool the internal air below the ambient 45°C. In fact, to reject heat, the internal temperature must be higher than the outside air. If the batteries require an operating temperature of 25°C to 35°C to maintain their lifecycle, a passive system is unlikely to meet the requirement of meeting the requirement. An active cooling loop is required to depress the internal temperature below ambient.

Scenario B: Roadside Urban Edge Cabinet

In urban environments, cabinets are often exposed to vehicle exhaust, brake dust, and corrosive pollutants. While the ambient temperature might be moderate, the requirement for ingress protection is high. Using open-loop cooling (fans) would pull particulate matter onto the PCBs, leading to short circuits or thermal insulation of components over time. A sealed enclosure is necessary to block contaminants.

However, sealing the cabinet traps heat. Without a mechanism to actively pump heat out of the sealed volume, the internal temperature will rise until equilibrium is reached, often at a level that degrades component reliability. Here, the constraint is not just temperature, but the combination of sealing and heat rejection.

Decision Matrix: Selecting the Right Thermal Strategy

Engineers must evaluate cooling technologies based on specific project criteria. The table below compares common approaches for outdoor telecom cabinets. Note that “Delta T” refers to the temperature headroom available for rejecting heat.

| Feature | Filter Fans (Open Loop) | Air-to-Air Heat Exchanger (HEX) | Thermoelectric (Peltier) | Micro DC Aircon (Compressor) |

|---|---|---|---|---|

| Sealing Capability | Low (IP54 max typically) | High (Closed Loop) | High (Closed Loop) | High (Closed Loop) |

| Sub-Ambient Cooling | Impossible | Impossible | Yes | Yes |

| Cooling Capacity | High (depends on airflow) | Medium (depends on Delta T) | Low (typically <200W) | High (100W–900W+) |

| Energy Efficiency (COP) | High | Medium | Low (0.5–0.8 typical) | High (2.0–3.0+ typical) |

| Dust/Salt Tolerance | Poor (requires filter changes) | Good | Good | Good |

| Best-Fit Scenario | Clean indoor/sheltered areas | Cool ambient, sealed cabinet | Low heat load, precise control | High heat, high ambient, sealed |

Implication: If your deployment requires the internal temperature to be lower than the outside air (sub-ambient) or if the ambient air is too hot to provide a sufficient Delta T for a heat exchanger, active refrigeration (Compressor or Peltier) is required. Between the two, compressor-based systems offer significantly higher efficiency (COP) and capacity for telecom loads.

Quick Selection Rules

Use these conditional rules during the design review phase to narrow down your thermal management options:

- Rule 1: If the target internal temperature is lower than the maximum ambient temperature, you typically need active refrigeration (Compressor or Peltier).

- Rule 2: If the heat load exceeds 200W–300W and power efficiency is a concern (e.g., solar/battery), a DC compressor system is usually preferred over Peltier due to higher Coefficient of Performance (COP).

- Rule 3: If the environment contains conductive dust, salt spray, or high humidity, an open-loop fan system is generally typically high risk; a closed-loop solution is necessary.

- Rule 4: If the site is powered by 48V DC (standard telecom voltage), selecting a native 48V DC cooling unit avoids the efficiency loss and failure points of an inverter.

- Rule 5: If the cabinet has limited surface area for passive radiation, the cooling unit must be sized to handle the total active heat load plus the solar load.

Failure Modes: The Unseen Enemies of Uptime

When thermal management strategies are mismatched with environmental realities, failure modes emerge that go beyond simple overheating. Understanding these mechanisms is critical for designing resilient systems.

Filter Clogging and Airflow Starvation

In fan-cooled systems, the filter is the single point of failure. In dusty environments, filters clog rapidly, increasing static pressure and reducing airflow. As airflow drops, the ability to reject heat diminishes linearly. This often leads to a “sawtooth” temperature profile where equipment runs hot, the filter is cleaned, and the cycle repeats. In remote locations, the cost of truck rolls to change filters often exceeds the cost of the hardware itself.

Battery Degradation

Lead-acid and Lithium-ion batteries are highly sensitive to temperature. sustained elevated temperature generally accelerates aging (exact impact is chemistry and vendor dependent). In a passive or fan-cooled cabinet, the batteries are often at the mercy of the ambient temperature. A micro ac for telecom cabinet application specifically targets this issue by maintaining a stable internal climate, preserving the energy storage investment.

Condensation and Corrosion

Humidity is a silent killer in sealed enclosures. As temperatures fluctuate between day and night, the air inside a cabinet expands and contracts. If the seal is imperfect, moist air is drawn in. When the cabinet cools at night, moisture condenses on cold surfaces, often PCBs or connectors. Active cooling systems with vapor compression cycles naturally dehumidify the air, collecting moisture as condensate which can be drained away, keeping the internal environment dry.

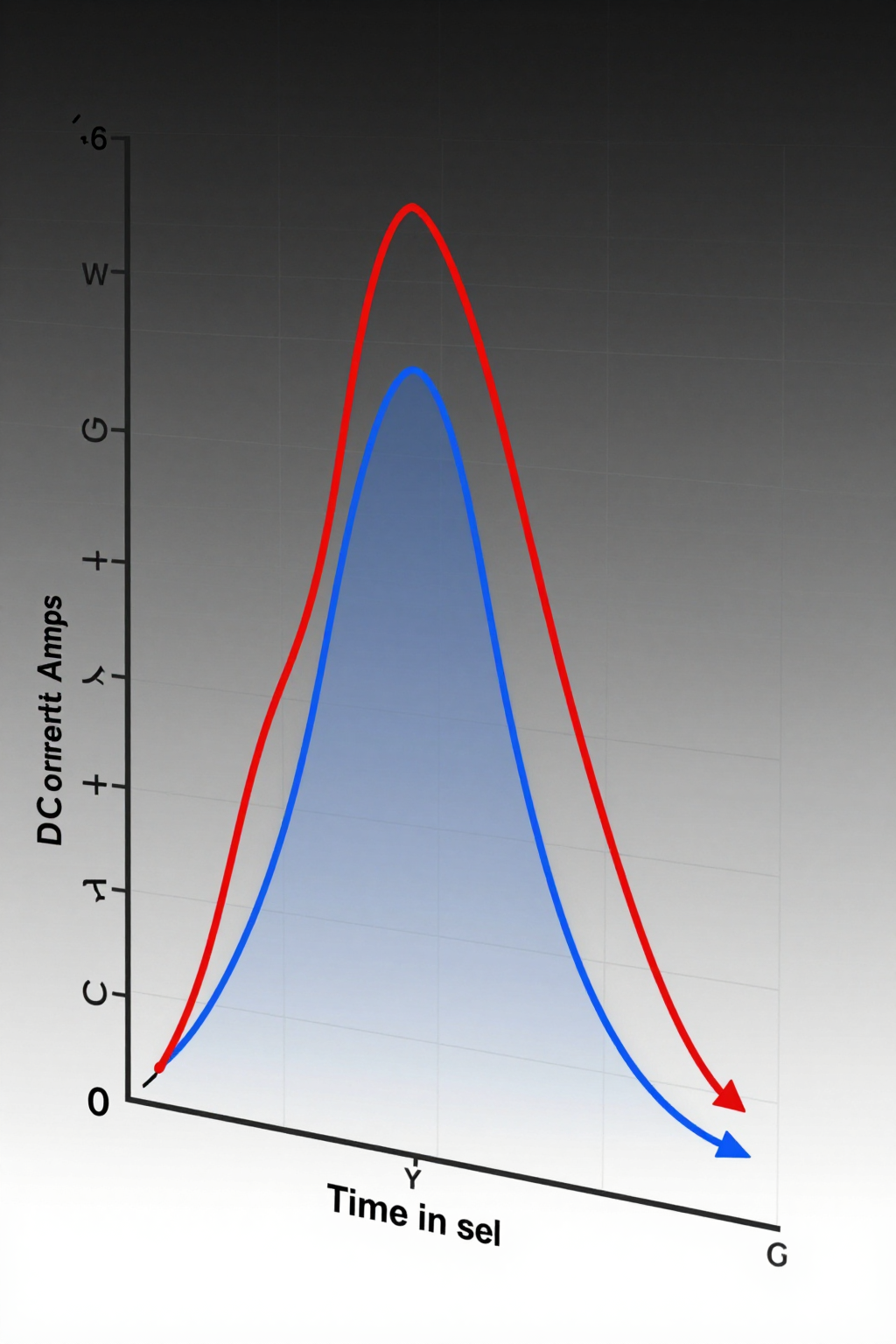

Inrush Current Trips

Older AC compressors often require a high starting current (locked rotor amperage) that can trip breakers or cause voltage sags in DC-powered systems. Modern variable-speed BLDC compressors utilize soft-start algorithms, ramping up speed gradually. This is crucial for off-grid or battery-backed telecom sites where power stability is paramount.

Engineering Fundamentals: Why Vapor Compression Works

To justify the integration of a micro DC air conditioner, it helps to understand the fundamental advantage of the vapor compression cycle over other methods. The core concept is “phase change.”

A refrigerant (such as R134a or R290) absorbs heat when it evaporates from a liquid to a gas and releases heat when it condenses back into a liquid. This phase change allows the system to move a large amount of thermal energy with a relatively small amount of electrical energy input. This ratio is the Coefficient of Performance (COP). A system with a COP of 3.0 moves 3 Watts of heat for every 1 Watt of electrical power consumed.

In contrast, Thermoelectric Coolers (TECs) use the Peltier effect, which relies on electron transport to move heat. This process is generally less efficient, often achieving a COP between 0.5 and 0.8. For a 400W heat load, a TEC might consume 500W–800W of power, whereas a vapor compression system might consume only 130W–200W. For telecom sites running on battery backup or solar, this efficiency gap is often the deciding factor.

Sealing Reality Clause: Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality.

Performance Data & Verified Specs

When selecting a cooling unit, engineers should look for verified specifications that match the power architecture of the telecom site. Most telecom infrastructure operates on 48V DC, though 12V and 24V systems exist for smaller nodes or automotive-derived applications.

The Arctic-tek Micro DC Aircon series (DV models) provides examples of the capacity and power characteristics available for these applications. The table below highlights key parameters for the Pro series models.

| Model | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a | Rotary BLDC Inverter |

| DV1920E-AC (Pro) | 24V | 450W | R134a | Rotary BLDC Inverter |

| DV1930E-AC (Pro) | 48V | 450W | R134a | Rotary BLDC Inverter |

| DV3220E-AC (Pro) | 24V | 550W | R134a | Rotary BLDC Inverter |

These units utilize a miniature DC compressor and a driver board (PCB) that manages the inverter control. This allows for variable speed operation, meaning the cooling capacity can modulate based on the load, rather than cycling on and off abruptly. This modulation improves efficiency and temperature stability.

For applications requiring even smaller footprints or custom integration, the Micro DC Aircon series offers a compact solution that can be embedded directly into the chassis of a telecom enclosure.

Field Implementation Checklist

Successful integration of a micro ac for telecom cabinet requires attention to mechanical and electrical details. A poor installation can negate the benefits of the hardware.

Mechanical Integration

- Airflow Management: Ensure the cold air discharge is not directed immediately back into the return intake (short-cycling). Use ducting or baffles if necessary to force cold air through the hot equipment.

- Condensate Drainage: Active cooling removes moisture. You must provide a gravity drain path for condensate. Ensure the drain tube has a trap or is routed to prevent insect ingress.

- Gasket Compression: Check that the mounting flange gasket is compressed evenly to maintain the NEMA/IP rating. Uneven torque on mounting screws can create gaps.

Electrical Integration

- Wire Sizing: Even with soft-start, ensure power cables are sized for the maximum current draw to prevent voltage drop. Undersized cables can cause the driver board to detect a low-voltage fault and shut down.

- Circuit Protection: Install a dedicated fuse or breaker for the cooling unit. Do not share the circuit with sensitive logic boards if possible, to isolate any potential noise, although modern drivers are well-filtered.

Thermal Considerations

- Solar Shielding: Whenever possible, install the cabinet or the cooling unit with a sunshield. Direct solar load can account for 30-50% of the total heat gain in a cabinet. Reducing this load reduces the work the compressor must do.

- Sensor Placement: If using an external temperature sensor for control, place it at the hottest point in the return air path, typically near the top of the cabinet, to ensure the system responds to the actual peak temperature.

Expert Field FAQ

Q: Can I run a DC air conditioner directly from the battery bank?

A: Yes, this is the standard configuration. The units are designed to operate on 12V, 24V, or 48V DC. You should ensure your battery bank has a low-voltage disconnect (LVD) that accounts for the air conditioner’s draw to prevent deep discharge during prolonged power outages.

Q: How does a micro ac for telecom cabinet handle dust clogging?

A: The condenser side (external) still requires airflow. While the internal loop is sealed, the external coil can accumulate dust. However, unlike filter fans, a reduction in external airflow reduces efficiency but does not immediately breach the cabinet seal. Many units use fin spacing designed to resist clogging, or require periodic cleaning (e.g., compressed air) rather than filter replacement.

Q: What is the maintenance interval?

A: In many deployments, these systems are “fit and forget” for long periods. The primary maintenance task is cleaning the external condenser coil. The interval depends on the site conditions (e.g., cottonwood, dust, industrial debris) but is typically much longer than filter fan replacement cycles.

Q: Is the cooling capacity constant?

A: No, it varies with ambient temperature and compressor speed. As the outside temperature rises, the capacity of any vapor compression system decreases slightly while power consumption increases. Sizing should always be based on the “worst-case” high ambient scenario.

Q: Can these units heat the cabinet in winter?

A: Some models offer a reverse cycle (heat pump) or have integrated electric heaters. However, the primary function is cooling. In most telecom applications, the equipment generates enough self-heat to stay warm, provided the cabinet is insulated. Heating is usually only required for cold-start scenarios.

Q: How do I size the unit for my cabinet?

A: You need to calculate the total heat load: Internal Heat Dissipation (Watts) + Solar Load (Watts) + Heat Transfer through walls (Watts). If you are unsure, it is safer to oversize slightly, as the inverter compressor can ramp down to match a lower load.

Conclusion & System Logic

The shift to edge computing and 5G has made thermal management a critical component of network reliability. Relying on passive cooling or simple fans is often insufficient for modern high-density, sealed enclosures exposed to harsh outdoor elements. The integration of a micro ac for telecom cabinet provides a robust solution that decouples the internal environment from the external weather.

By utilizing efficient DC inverter compressors, engineers can achieve sub-ambient cooling without the energy penalty associated with older technologies. This approach ensures that critical equipment operates within its optimal temperature range, extending component life and preventing service-impacting thermal throttling. When the cost of downtime and battery replacement is factored in, the ROI of active cooling in harsh environments becomes clear.

Request Sizing Assistance

Selecting the correct cooling capacity is critical to balancing performance and power consumption. To receive a detailed sizing recommendation for your specific application, please prepare the following inputs and contact our engineering team:

- Ambient Conditions: Maximum expected outdoor temperature and solar exposure level.

- Target Temperature: Desired internal temperature (e.g., 25°C for batteries).

- Heat Load: Total power dissipation of internal equipment (Watts).

- Power Source: Available DC voltage (12V, 24V, 48V) and current limits.

- Enclosure Details: Dimensions, material, and insulation type.

- Sealing Requirement: Target IP or NEMA rating.

For more information on specific components, you can view our DC condensing unit options suitable for custom integration.

0 条评论