Angle: The decision to upgrade from a seemingly simple fan-and-filter system to a closed-loop active cooling solution. Key failure modes are thermal shutdown from clogged filters and contamination of sensitive electronics from dust ingress. The dominant constraint is the high concentration of airborne particulates in an industrial environment.

Why Fan Filters Fail: The Case for a Micro DC Air Conditioner in a Dusty Factory Cabinet

On any factory floor, the electrical enclosure is the nerve center. It houses the PLCs, VFDs, and power supplies that orchestrate production. The default solution for cooling these critical components has long been the humble fan-and-filter unit. It’s inexpensive, simple to install, and seems effective—until it isn’t. In environments with high levels of airborne particulates, from metal shavings in a CNC shop to fibrous lint in a textile mill, this simple solution quickly becomes a high-maintenance liability, leading to production halts and premature component failure. The constant cycle of cleaning and replacing clogged filters introduces significant operational costs and risks that are often overlooked during initial system design.

This article provides a data-driven analysis for engineers and system integrators facing this exact problem. We will dissect the failure modes of open-loop cooling in particulate-heavy environments and lay out the engineering criteria for selecting a more robust, reliable solution. By the end, you will be able to determine the precise threshold at which a sealed, active cooling system, such as a micro dc air conditioner dusty factory cabinet unit, transitions from a perceived luxury to an operational necessity. We will prioritize long-term reliability and total cost of ownership over initial component price, focusing on how to create a stable, protected internal environment for your electronics, regardless of external conditions.

Deployment Context: Where Simple Cooling Becomes a Complex Problem

The theoretical efficiency of a fan-filter system rarely survives contact with the realities of an industrial environment. Two common scenarios illustrate the rapid breakdown of this approach.

Scenario A: CNC Machining and Metal Fabrication

A fabrication shop runs multiple CNC mills, lathes, and grinders. The air is consistently filled with fine, often conductive, metallic dust and aerosolized cutting fluids. The control cabinet for a primary milling center, cooled by two fan-filter units, begins to experience intermittent faults. Maintenance discovers the exhaust filter is completely blocked with a dense, oily cake of metal dust. After replacement, the same issue occurs within two weeks. The frequent filter changes are logged as routine maintenance, but the root cause—unreliable cooling and potential dust ingress—is creating a significant risk of a multi-thousand-dollar VFD failure and unplanned line stoppage.

Scenario B: Textile and Woodworking Facilities

In a textile processing plant, the air is thick with fibrous lint. A control cabinet managing a series of automated looms relies on fan cooling. The intake filters clog weekly, drastically reducing airflow. The internal temperature of the cabinet begins to climb, causing the PLC to derate its performance to avoid overheating, which slows the entire production line. An operator, trying to solve the immediate problem, removes the filter entirely. Within a month, a thick blanket of flammable lint has coated every component, creating a severe fire hazard and causing a power supply to fail from overheating.

Failure Modes & Constraints of Open-Loop Cooling

When evaluating thermal management in dusty environments, the problems extend beyond simple temperature control. The following failure modes are ranked by their likelihood and potential impact on operations.

- Airflow Starvation → Overheating → The primary failure. Clogged filters reduce airflow to near zero, causing internal temperatures to rise rapidly and leading to thermal shutdown or component damage.

- Dust Ingress → Component Contamination → Degraded gaskets or improper filter seating allows dust to bypass the filter, coating circuit boards, shorting connections, and fouling VFD heat sinks.

- Increased Maintenance Cycles → High Labor Costs → The need for weekly or bi-weekly filter cleaning/replacement consumes valuable maintenance hours and increases the total cost of ownership far beyond the initial hardware price.

- Reduced Component Lifespan → Capital Expense → Consistently operating electronics at elevated temperatures, even if below the shutdown threshold, dramatically shortens their operational life, forcing premature replacement.

- Fire Hazard → Catastrophic Failure → In environments with flammable dust (e.g., wood, flour, textiles), accumulation inside a hot electrical cabinet creates a severe, often overlooked, fire risk.

- Conductive Dust Infiltration → Electrical Shorts → In metalworking environments, conductive dust can cause immediate and catastrophic short circuits on power supplies and control boards.

- Unpredictable Performance → Production Instability → As filters slowly clog, the cooling performance degrades unpredictably, leading to intermittent and hard-to-diagnose electronic faults that can disrupt production schedules.

Engineering Fundamentals: Closed-Loop vs. Open-Loop Cooling

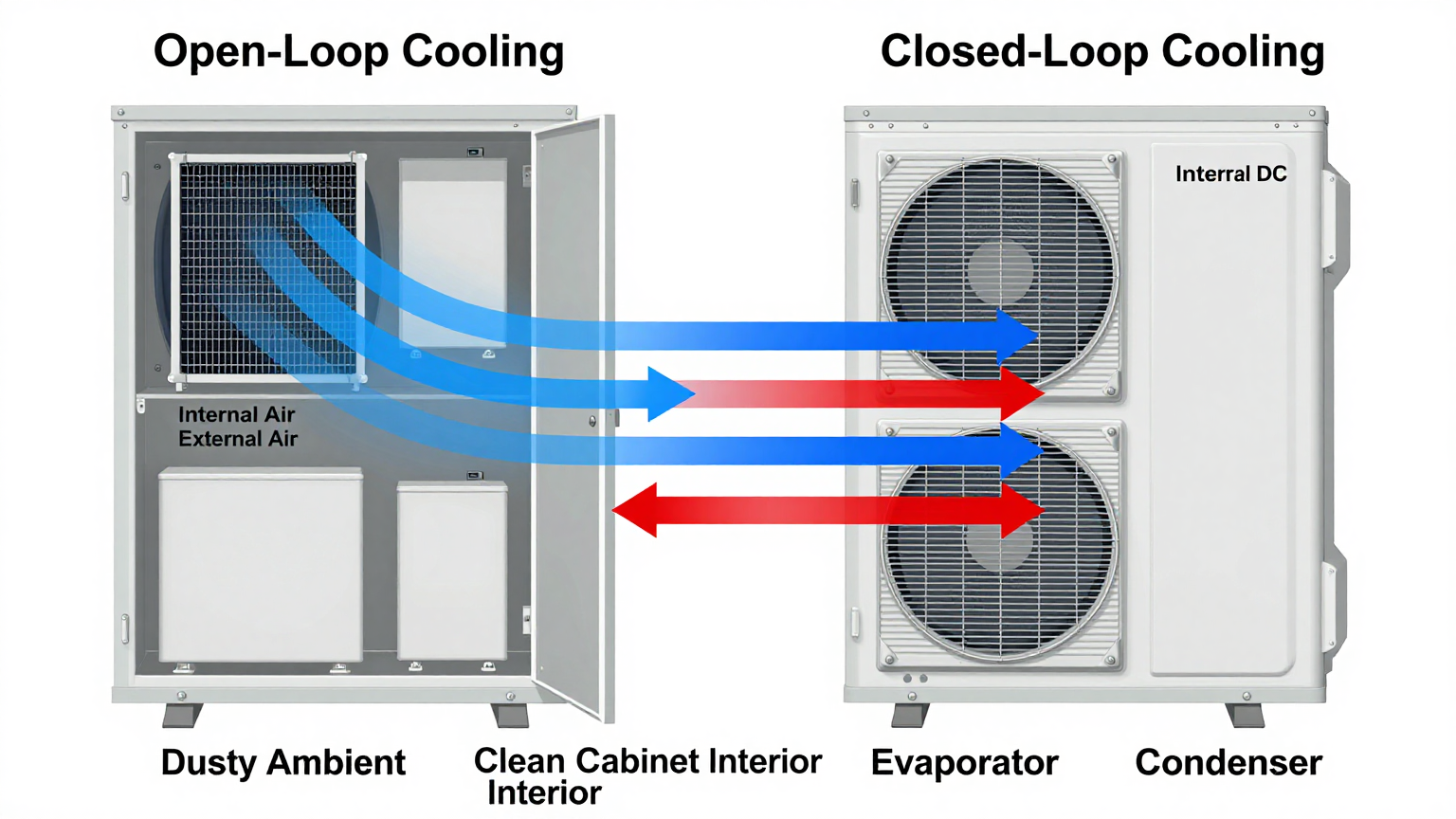

The core issue in these scenarios is the cooling methodology itself. Fan-and-filter systems are open-loop. They operate by pulling ambient factory air into the enclosure, flowing it over the electronics to pick up heat, and exhausting it. This design is fundamentally dependent on the quality of the ambient air. When that air is contaminated, the system actively imports the contaminant into the very space it is meant to protect.

A micro dc air conditioner dusty factory cabinet operates on a closed-loop principle. It creates two completely separate air paths. The internal loop circulates and cools the air already inside the enclosure, never mixing it with the outside environment. The external loop pulls ambient air across the condenser coils to expel the collected heat to the outside. This separation is the critical difference. It allows the system to maintain a clean, cool, and controlled environment inside the cabinet, regardless of how dusty or dirty the external factory air is. This is the only way to reliably protect sensitive electronics in harsh environments.

Common Misconception: “If my cabinet is overheating, I just need a more powerful fan.”

Engineering Correction: A more powerful fan will not solve a filter-clogging problem. In fact, a higher flow rate can pull particulates into the filter media more aggressively, potentially accelerating the clogging process. It also does nothing to prevent dust ingress if the enclosure’s seals are not perfect. Furthermore, a fan can never cool the internal temperature below the ambient factory air temperature. If the factory floor is 35°C and the electronics require a 30°C environment, a fan is physically incapable of meeting the requirement. This is where a proper thermal management solution like a micro DC air conditioner becomes essential.

Key Specifications for a DC Enclosure Air Conditioner in a Dusty Environment

When selecting a closed-loop cooling solution, certain specifications are non-negotiable for ensuring performance and reliability in a dusty factory. The table below shows example parameters for our Micro DC Aircon series. The key is to match the voltage and cooling capacity to the specific demands of your enclosure.

| Model (Example) | Input Voltage | Nominal Cooling Capacity | Refrigerant |

|---|---|---|---|

| DV1910E-AC (Pro) | 12V DC | 450W | R134a |

| DV1920E-AC (Pro) | 24V DC | 450W | R134a |

| DV1930E-AC (Pro) | 48V DC | 450W | R134a |

| DV3220E-AC (Pro) | 24V DC | 550W | R134a |

How to read these specs for our decision:

- Input Voltage (12V/24V/48V DC): This is a primary integration constraint. The cooling unit must match the DC power bus available within your control cabinet. 24V DC is a common standard in industrial automation.

- Nominal Cooling Capacity (Watts): This figure must exceed the total heat load generated by the components inside the cabinet. Accurately calculating the heat load from VFDs, power supplies, and processors is the most critical step in sizing the unit correctly. Always design with a safety margin of 20-25%.

- Physical Dimensions & Mounting: The unit must physically fit the available space on the cabinet door or side wall without obstructing access or violating clearance requirements for other components.

- Environmental Sealing (NEMA/IP Rating): While specific ratings vary by model and installation, the design of a micro dc air conditioner dusty factory cabinet inherently provides a seal to protect against dust and moisture ingress, a feature fundamentally absent in fan-filter systems.

Engineering Selection Matrix: From Fan to Active Cooling

An engineer’s decision to upgrade from a fan to a micro DC air conditioner is not based on preference, but on passing a series of logic gates dictated by the application’s constraints.

Logic Gate 1: The Contamination Gate

- Constraint Gate: Environmental Particulate Level vs. Required Internal Cleanliness.

- Decision Trigger: If the external environment contains conductive dust, flammable fibers, oil mist, or corrosive agents that must not enter the enclosure, an open-loop system is immediately disqualified. This is often codified by a requirement for a NEMA 12, 4, or IP55 rating or higher.

- Engineering Resolution: The requirement for a sealed enclosure mandates a closed-loop cooling architecture. This shifts the selection from any fan-based system to either a heat exchanger (if sub-ambient cooling is not needed) or an active micro dc air conditioner dusty factory cabinet.

- Integration Trade-off: The upfront capital cost is higher than a fan, but this is offset by eliminating the risk of contamination-induced component failure and associated production downtime.

Logic Gate 2: The Thermal Delta Gate

- Constraint Gate: Maximum Allowable Internal Temperature vs. Maximum Ambient Factory Temperature.

- Decision Trigger: If the maximum allowable internal cabinet temperature is less than or equal to the peak ambient temperature on the factory floor, a fan or heat exchanger cannot work. These systems can only achieve a temperature *above* ambient.

- Engineering Resolution: The need for sub-ambient cooling mandates an active refrigeration cycle. A vapor-compression system, like that in a micro DC air conditioner, is required to actively pump heat out of the enclosure and achieve an internal temperature lower than the surrounding air.

- Integration Trade-off: This introduces a higher power draw on the DC bus compared to a simple fan. The power supply must be sized to handle the compressor’s load, but it ensures electronics operate within their optimal temperature range, maximizing performance and lifespan.

Logic Gate 3: The Operational Cost Gate

- Constraint Gate: Maintenance Labor Cost vs. Hardware Capital Cost.

- Decision Trigger: If the calculated annual cost of labor for filter inspection and replacement, plus the cost of replacement filters, approaches or exceeds the amortized cost of an active cooling unit, the fan-filter system is no longer economically viable. For example, if a filter change takes 30 minutes of a technician’s time and is required weekly, that’s 26 hours of labor per year, per cabinet.

- Engineering Resolution: Shift to a low-maintenance cooling solution. A micro dc air conditioner dusty factory cabinet requires only periodic (e.g., quarterly or semi-annual) inspection and cleaning of its external condenser coils—a much less frequent and often faster task than replacing clogged filters.

- Integration Trade-off: A higher initial investment is required, but it delivers a predictable maintenance schedule and a rapid return on investment through drastically reduced labor costs and minimized downtime risk. This is a classic Total Cost of Ownership (TCO) decision.

Implementation Checklist for a Micro DC Aircon

Proper installation is critical to realizing the benefits of a closed-loop system. A flawed installation can compromise the seal and negate the primary advantage of the upgrade.

-

Mechanical Installation

- Sealing Surface: Ensure the cabinet mounting surface is flat, clean, and free of debris. Use the supplied gasket and verify a continuous, compressed seal around the entire perimeter of the unit’s cutout. This is the most critical step for preventing dust ingress.

- Mounting: Use all specified mounting points and torque fasteners to the recommended values to ensure a secure, vibration-resistant fit.

- Airflow Integrity: Verify that internal and external airflow paths are unobstructed. Ensure components inside the cabinet do not block the cold air outlet and that the external condenser has adequate clearance for heat rejection.

-

Electrical Connection

- Power Budget: Confirm that the DC power supply unit (PSU) in the cabinet can handle the air conditioner’s peak current draw, especially during compressor startup. Use dedicated, appropriately gauged wiring.

- Circuit Protection: Install the recommended fuse or circuit breaker in line with the unit to protect both the air conditioner and the power supply.

- Control Wiring: If using remote alarms or thermostat controls, ensure wiring is routed away from high-voltage AC lines to prevent interference.

-

Thermal Verification

- Sensor Placement: Place an independent temperature sensor in the upper third of the cabinet, away from the direct cold air stream, to get an accurate reading of the average internal temperature.

- Acceptance Test: After installation, run the system under a typical heat load. Verify that the unit cycles correctly and maintains the internal setpoint temperature as the ambient factory temperature fluctuates.

-

Maintenance Planning

- Access: Ensure the installed unit remains accessible for future maintenance without requiring the disassembly of other machinery.

- Inspection Trigger: Establish a periodic maintenance schedule (e.g., quarterly) to inspect the external condenser coils for dust buildup. The frequency will depend on the severity of the environment. A clogged condenser coil will reduce efficiency and cooling performance.

Frequently Asked Questions (FAQ)

Should I choose a heat exchanger or a micro DC air conditioner for a dusty factory cabinet?

A heat exchanger is also a closed-loop system, which is good for dust protection. However, it can only cool the inside of the cabinet to a temperature *above* the outside ambient air. If your factory floor reaches 40°C, a heat exchanger might only be able to keep the cabinet at 45°C. If you need to maintain 35°C or lower, a micro dc air conditioner dusty factory cabinet is the necessary choice because it provides active refrigeration.

How does a sealed enclosure deal with condensation?

Active air conditioners cool the air to its dew point, which can create condensation. Our Micro DC Aircon units are designed with integrated condensate management. This typically involves collecting the moisture from the internal evaporator coil and routing it to an external evaporation pan on the hot condenser side, where it is safely dissipated outside the enclosure.

What if my cabinet is exposed to direct sun or other external heat sources?

Direct solar radiation adds a significant external heat load to the enclosure. This load must be calculated and added to the internal heat load from the electronics. When sizing a cooling unit, you must account for the total heat load (internal + external) to ensure the unit has enough capacity to maintain the target temperature on the hottest, sunniest days.

What is the first thing I need to measure before selecting a cooling unit?

The two most critical measurements are the internal heat load (in watts) and the maximum expected ambient temperature. You can estimate the heat load by summing the power consumption of all components and assuming a high percentage is converted to heat. For ambient temperature, measure it during the hottest part of the day and the year to establish a true worst-case scenario.

How can I validate that the cooling solution is working correctly after installation?

The best method is data logging. Place a temperature logger inside the cabinet and record the internal temperature over a full production cycle, including periods of peak load and high ambient heat. The data should show the temperature remaining stable and at or below your desired setpoint, proving the system is sized and functioning correctly.

Can’t I just use a bigger filter or a pleated filter to extend maintenance intervals?

While higher-capacity filters can modestly extend service intervals, they do not change the fundamental problem of open-loop cooling. They still require replacement, still pose a risk of clogging, and do nothing to protect against gasket leaks or provide sub-ambient cooling. It is a temporary patch, not a robust engineering solution for a challenging environment.

Conclusion: The Right Tool for a Demanding Job

For clean, climate-controlled environments, fan-and-filter systems remain a cost-effective choice for cabinet cooling. However, the operational realities of a dusty factory floor expose their fundamental weaknesses. The constant battle against clogged filters, the risk of contamination, and the inability to cool below ambient temperatures create a cycle of excessive maintenance and unpredictable reliability.

The best-fit solution is dictated by the constraints of the environment. When the air is filled with particulates and reliable operation is paramount, a closed-loop system is the only viable path. A micro dc air conditioner dusty factory cabinet solution provides a stable, clean, and controlled internal environment, insulating your critical electronics from the harsh conditions outside. It represents a strategic shift from reactive maintenance to proactive system reliability, reducing the total cost of ownership and ensuring your automation assets are protected.

If you are facing challenges with electrical cabinet overheating in harsh industrial settings, our engineering team can help you accurately calculate your heat load and select a cooling solution tailored to your specific power constraints, enclosure geometry, and environmental challenges.

0 条评论