Managing Thermal Density in High-Performance Motion Control

As servo drive technology advances, the physical footprint of motion control components continues to shrink while power density increases. For OEM engineers and system integrators, this creates a significant thermal challenge. The reduction in cabinet volume, combined with the high switching frequencies of modern drives, often results in localized hotspots that passive dissipation cannot resolve. When internal enclosure temperatures rise above the rated operating limits of servo drives—near common component operating limits for full performance—the system protects itself through derating or thermal shutdowns.

In environments where ambient air is contaminated with dust, oil mist, or conductive debris, drawing outside air through the enclosure is rarely a viable strategy. This drives the need for closed-loop cooling solutions. Integrating a micro ac for servo drive cabinet applications allows engineers to maintain a sealed environment while actively rejecting heat, ensuring that internal temperatures remain stable regardless of external conditions. This article examines the engineering logic behind selecting active cooling for motion control, focusing on the constraints of mobile, remote, and harsh industrial deployments.

Deployment Context: Where Passive Cooling Fails

To understand the necessity of active cooling, we must look at specific deployment scenarios where standard convection or fan-and-filter methods are insufficient. The following scenarios illustrate common constraints found in robotics and industrial automation.

Scenario A: Autonomous Mobile Robots (AMRs)

In mobile robotics, the control cabinet is often embedded deep within the chassis to protect it from collisions and debris. This location restricts natural airflow around the enclosure exterior.

- Constraints: The power source is a DC battery bank (typically 24V or 48V). The enclosure must be sealed (IP54 or higher) to prevent ingress of floor dust and moisture.

- Thermal Load: Servo drives for traction and lift motors generate variable heat loads that peak during acceleration.

- Challenge: The ambient air surrounding the internal cabinet is often pre-heated by the battery packs and motors, reducing the Delta T available for passive heat transfer.

Scenario B: CNC and Machining Centers

Control cabinets for CNC machines are frequently exposed to airborne oil mist and metal particulates.

- Constraints: The enclosure requires NEMA 4 or IP65-level sealing to prevent short circuits on the drive PCBs caused by conductive debris.

- Thermal Load: Multi-axis servo systems operate at high duty cycles, generating continuous heat.

- Challenge: Using fans to pull in ambient air would introduce contaminants. A closed-loop system is required, but the factory floor ambient temperature may exceed 35°C, rendering passive heat exchangers ineffective.

Decision Matrix: Selecting the Right Thermal Strategy

When designing a cooling strategy for a sealed enclosure, engineers typically evaluate three primary technologies: Air-to-Air Heat Exchangers (or simply oversized surface area), Thermoelectric Coolers (Peltier), and Vapor Compression Cycle (Micro DC Aircon). The following table compares these approaches based on criteria critical to motion control.

| Criteria | Passive / Heat Exchanger | Thermoelectric (TEC/Peltier) | Micro DC Aircon (Compressor) |

|---|---|---|---|

| Sub-Ambient Cooling | Not Possible (Internal T > Ambient T) | Yes (Limited Capacity) | Yes (High Capacity) |

| Cooling Capacity (Typical) | Dependent on Surface Area | Typically < 200W | higher heat loads (depends on configuration) |

| Efficiency (COP) | N/A (Passive) | lower cooling-per-watt trend | higher cooling-per-watt trend |

| Power Draw Impact | Negligible (Fans only) | High Current Draw | Moderate (Inverter Controlled) |

| Sealed Enclosure Suitability | Yes (if closed loop) | Yes | Yes |

| Response to Load Spikes | Slow (Thermal Mass dependent) | Fast, but limited headroom | Fast (Variable Speed Compressor) |

Implication: While passive methods are reliable for low-density electronics, they fail when the ambient temperature approaches the target internal temperature. Thermoelectric coolers offer precise control but often struggle with the heat loads generated by multi-axis servo systems (300W+). For loads exceeding 200-300W in a sealed volume, vapor compression typically offers the most favorable balance of size, weight, and power consumption.

Quick Selection Rules for Design Reviews

Use these conditional rules to narrow down the technology choice during the design phase:

- IF the ambient temperature is consistently 10°C lower than the maximum allowable internal temperature, THEN a passive heat exchanger or filtered fan may suffice (assuming air quality permits).

- IF the enclosure must be sealed (NEMA 4/IP65) AND the heat load exceeds 300W, THEN a micro DC air conditioner is often the most viable option.

- IF the power source is battery-limited (AGV/AMR), THEN compare the COP; compressor-based systems typically draw typically higher cooling-per-watt than TEC in many deployments than Peltier modules.

- IF the application requires cooling below ambient temperature to prevent component derating, THEN passive cooling is disqualified.

- IF vibration is significant, THEN ensure the cooling unit (whether TEC or compressor) is rated for mobile deployment or mounted with isolation dampeners.

Failure Modes: The Unseen Enemies of Uptime

In motion control applications, thermal management is not just about preventing immediate shutdown; it is about preserving component life. Servo drives and variable frequency drives (VFDs) are particularly sensitive to heat-induced degradation.

IGBT Junction Overheating

The Insulated Gate Bipolar Transistors (IGBTs) in servo drives switch at high frequencies (carrier frequencies). As the junction temperature rises, the drive’s firmware will often automatically lower the switching frequency to reduce heat generation. This “derating” can lead to audible noise in the motor, reduced torque precision, or system instability. If the temperature continues to rise, the drive will trip on an over-temperature fault, causing immediate machine downtime.

DC Bus Capacitor Degradation

Electrolytic capacitors on the DC bus are critical for smoothing voltage. Their operational life is governed by the Arrhenius equation, which generally suggests that for every 10°C rise in operating temperature, the component life is cut in half. Running a cabinet at 55°C instead of 35°C can drastically shorten the maintenance interval for expensive drive components.

Nuisance Tripping

Localized hotspots can form around the drive’s heat sink if airflow is stagnant. A sensor reading a hotspot may trigger a system alarm even if the average cabinet temperature is within limits. This results in “nuisance trips” that are difficult to diagnose and often lead operators to run cabinets with doors open—a practice that introduces dust and violates safety standards.

Engineering Fundamentals: Why Active Cooling Works

To solve these issues, engineers must shift from thinking about “ventilation” to thinking about “heat rejection.”

The Delta T Limitation

Passive cooling relies entirely on the temperature difference (Delta T) between the inside of the cabinet and the outside air. Heat naturally flows from hot to cold. As the outside ambient temperature rises, the Delta T shrinks, and the rate of heat transfer drops. Once the ambient air reaches the target internal temperature (e.g., 40°C), heat transfer stops completely, and the internal temperature will continue to rise until components fail.

Vapor Compression Advantage

A micro ac for servo drive cabinet applications utilizes a vapor compression cycle. This system uses a refrigerant (such as R134a or R290) to absorb heat from the internal air and reject it to the external air, even if the external air is hotter than the inside. By using a compressor to elevate the pressure and temperature of the refrigerant, the system creates an artificial Delta T, allowing it to “pump” heat “uphill” against the thermal gradient.

Closed-Loop Integrity

Active cooling units recirculate the air inside the cabinet. The internal air passes over a cold evaporator coil, which removes heat and condenses moisture. This cool, dry air is then blown back over the servo drives. Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality.

Performance Data & Verified Specifications

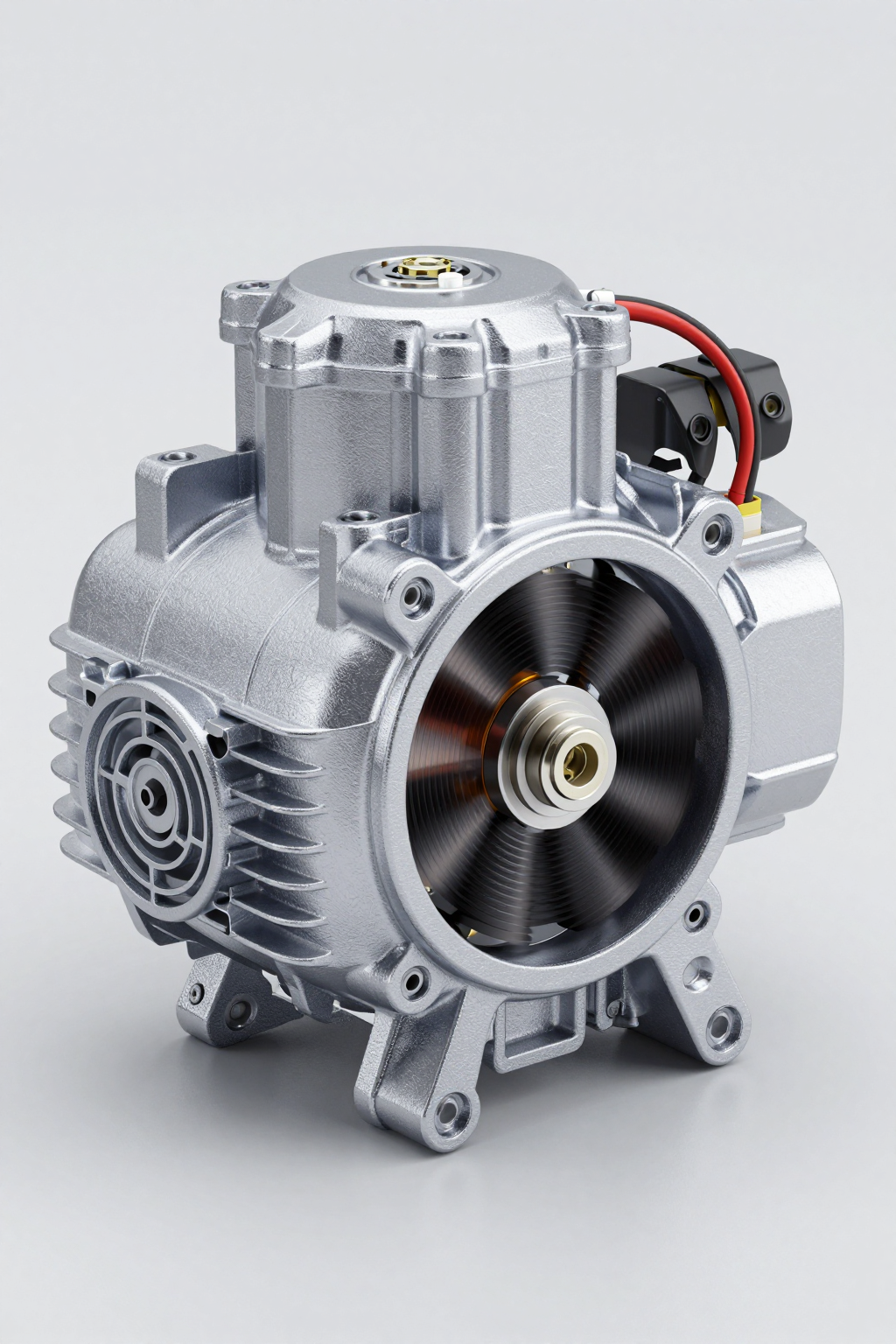

When specifying a micro DC air conditioner, it is critical to align the cooling capacity with the estimated heat load. The following table outlines the specifications for the Arctic-tek Micro DC Aircon series, which utilizes miniature BLDC rotary compressors for high efficiency in compact form factors.

| Model (Example) | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a | Miniature BLDC Rotary |

| DV1920E-AC (Pro) | 24V | 450W | R134a | Miniature BLDC Rotary |

| DV1930E-AC (Pro) | 48V | 450W | R134a | Miniature BLDC Rotary |

| DV3220E-AC (Pro) | 24V | 550W | R134a | Miniature BLDC Rotary |

Note: Cooling capacity varies based on ambient temperature and internal setpoint. The values above represent nominal performance.

For applications requiring integration into custom chassis, engineers may also consider component-level solutions such as the Micro DC Aircon modules or standalone DC condensing units. These allow for flexible placement of the evaporator and condenser to fit irregular spaces in robotics.

Field Implementation Checklist

Successful integration of a micro AC unit requires attention to mechanical and electrical details. A poorly installed unit can lead to short-cycling or power faults.

Mechanical Integration

- Airflow Management: Ensure the cold air discharge from the AC unit is not blown directly into the intake of the servo drive fans if they are opposing. Ideally, direct cold air to the bottom of the cabinet (or the intake zone of the drives) and allow hot air to rise to the AC return.

- Short-Cycling Prevention: Do not place obstructions immediately in front of the AC unit’s supply or return vents. Short-cycling occurs when cold air is immediately sucked back into the return, causing the thermostat to satisfy prematurely while the rest of the cabinet remains hot.

- Vibration Dampening: For mobile robots, use thread-lockers on mounting bolts and consider rubber isolation grommets if the chassis vibration is high frequency.

Electrical Integration

- Inrush Current: While inverter-driven BLDC compressors have soft-start capabilities, ensure the power supply or battery BMS can handle the transient load during startup.

- Wire Sizing: Undersized DC wiring causes voltage drop. If the voltage at the compressor terminals drops below the under-voltage cutoff threshold (e.g., below the low-voltage cutoff threshold for a 12V system) during operation, the unit will fault.

- Condensate Management: Active cooling removes humidity. Ensure the condensate drain tube is routed correctly to the exterior and is not kinked. In sealed mobile units, a wicking evaporator or collection bottle may be required if gravity drainage is not possible.

Expert Field FAQ

Q: Can a micro AC for servo drive cabinet applications run directly off the servo power supply?

A: It depends on the capacity. A 24V or 48V DC aircon can often share the DC bus or auxiliary supply used for controls, provided the power supply has sufficient overhead (amperage) to handle the compressor load plus the control logic without sagging.

Q: How does the system handle condensation in a sealed enclosure?

A: As the unit cools, moisture condenses on the evaporator coil. Standard units rely on gravity drainage via a tube. In mobile robotics where orientation changes or gravity drainage is difficult, absorbent sponges or active condensate evaporation systems may be needed.

Q: What is the maintenance interval for these units?

A: The primary maintenance task is cleaning the external condenser filter or fin stack. If the environment is oily or dusty, this might be required monthly. The internal refrigeration loop is hermetically sealed and typically requires no maintenance.

Q: Does the compressor run continuously?

A: Most modern micro DC air conditioners use inverter technology. The compressor speeds up or slows down to match the heat load, rather than cycling on and off. This maintains a more stable internal temperature and reduces mechanical stress.

Q: Can I use a 12V unit on a 24V system with a step-down converter?

A: While possible, it introduces inefficiency and another point of failure. It is generally recommended to match the cooling unit voltage to the native system voltage (e.g., use a DV1920E-AC for a 24V bus) to maximize efficiency.

Q: How much battery capacity does the cooling unit consume?

A: This depends on the duty cycle. A 450W cooling unit might draw ~150-200W of electrical power. If the duty cycle is 50%, the average draw is ~75-100W. Engineers must factor this into the vehicle’s total energy budget.

Conclusion & System Logic

The transition to high-density motion control requires a re-evaluation of thermal management strategies. Passive cooling is often insufficient for sealed cabinets housing modern servo drives, especially in harsh or mobile environments. By integrating a micro ac for servo drive cabinet designs, engineers can decouple the internal operating environment from external conditions.

The logic for selection is straightforward: if the application demands a sealed enclosure and the heat load exceeds the capacity of passive dissipation (typically >200W in small volumes), active compressor-based cooling provides the necessary thermal headroom. This approach protects critical IGBTs, extends capacitor life, and prevents nuisance tripping, ultimately securing the reliability of the automation system.

Request Sizing Assistance

Selecting the correct cooling capacity is critical to avoid oversizing (wasteful weight/power) or undersizing (thermal failure). To receive a specific recommendation for your application, please prepare the following inputs and contact our engineering team:

- Target Internal Temperature: (e.g., 35°C)

- Maximum Ambient Temperature: (e.g., 45°C)

- Estimated Heat Load: (Total Watts of all active components)

- Power Source: (Voltage and available current limit)

- Enclosure Dimensions: (H x W x D)

- Sealing Requirement: (NEMA/IP rating)

0 条评论