Angle Lock: The decision is between continuing with high-maintenance fan-and-filter systems or investing in a closed-loop solution. The primary failure modes are catastrophic component failure from dust contamination and production halts from thermal shutdowns. The dominant constraint is the high concentration of airborne particulates in the operating environment.

Why Fan Filters Fail: Choosing a Micro DC Air Conditioner for a Dusty Factory Cabinet

On a factory floor—be it woodworking, metal fabrication, or textile processing—the air is thick with performance-killing particulate. For the electrical cabinets that house PLCs, VFDs, and power supplies, this dust isn’t just a nuisance; it’s a direct threat to operational uptime. The common solution, a simple fan and filter assembly, often becomes the source of the problem. It pulls in contaminated air, filters clog faster than maintenance schedules can keep up, and sensitive electronics begin to cook. The stakes aren’t just a single component failure; they are unplanned line stoppages, missed production targets, and escalating maintenance labor costs. By the end of this analysis, you will be able to determine the precise operational threshold where a closed-loop micro dc air conditioner for a dusty factory cabinet transitions from a perceived luxury to a mission-critical necessity. In this article, we prioritize long-term system reliability and total cost of ownership over minimal upfront component cost, because industrial environments punish short-term thinking.

Deployment Context: Where Open-Loop Cooling Fails

Understanding the failure point of traditional cooling helps clarify the need for a more robust approach. These are not edge cases; they are common scenarios where the wrong cooling choice directly impacts the bottom line.

Scenario A: CNC Machining Floor

A cabinet controlling a multi-axis CNC machine is situated near the milling area. It’s protected from direct coolant spray but not from the fine metal and composite dust that hangs in the air. The cabinet’s fan filter, designed for a cleaner environment, clogs within two weeks, drastically reducing airflow. The VFD inside, now starved of cooling, begins to derate its performance to protect itself, causing slower tool speeds and visible quality issues in the finished parts. A maintenance technician replaces the filter, restoring performance, but the cycle repeats, creating a hidden drag on production efficiency and introducing a recurring maintenance task that is easily missed during busy periods.

Scenario B: Food Processing & Packaging Plant

In a facility that processes flour, spices, or other powders, a control cabinet for a packaging line is experiencing intermittent faults. The environment is not only dusty but also subject to high ambient temperatures in the summer. The installed fan-and-filter unit, even with a clean filter, cannot cool the internal temperature below the ambient factory air temperature. On a 35°C day, the cabinet’s internal temperature climbs to over 45°C, causing the primary PLC to fault randomly. The maintenance team can’t find a root cause because the issue disappears on cooler days, leading to wasted diagnostic hours and a growing distrust in the control system’s reliability. The core problem is a fundamental mismatch between the cooling method and the thermal reality.

Failure Modes & Constraints in Dusty Environments

When evaluating cooling for industrial enclosures, the risks are predictable and cumulative. The most common issues stem from the interaction between airborne dust and the chosen thermal management strategy.

- Symptom: Rapidly decreasing airflow from vents. → Cause: Surface clogging of filter media. → Why it matters: Leads to immediate thermal buildup and component derating.

- Symptom: A fine layer of dust inside a “sealed” cabinet. → Cause: Negative pressure from fans pulling dust through imperfect gaskets and cable glands. → Why it matters: Conductive dust can short circuit boards, while abrasive dust accelerates wear on moving parts like relays.

- Symptom: Increased fan noise or motor strain. → Cause: Fan working harder to pull air through a clogged filter. → Why it matters: Precursor to premature fan motor failure, leading to a total loss of cooling.

- Symptom: Intermittent electronic faults on hot days. → Cause: Inability of ambient-air cooling to keep components below their maximum operating temperature. → Why it matters: Reduces system reliability, causes phantom errors, and shortens the lifespan of expensive electronics.

- Symptom: Spiking maintenance labor hours for a specific set of assets. → Cause: Reactive filter replacement schedule driven by alarms instead of preventative planning. → Why it matters: Diverts skilled technicians from value-added work to a low-skill, repetitive task that could be engineered out.

- Symptom: Visible corrosion on internal components. → Cause: Fans pulling in humid, contaminated air that reaches its dew point inside the cooler cabinet. → Why it matters: Moisture combined with dust creates a corrosive sludge that degrades PCBs and connections.

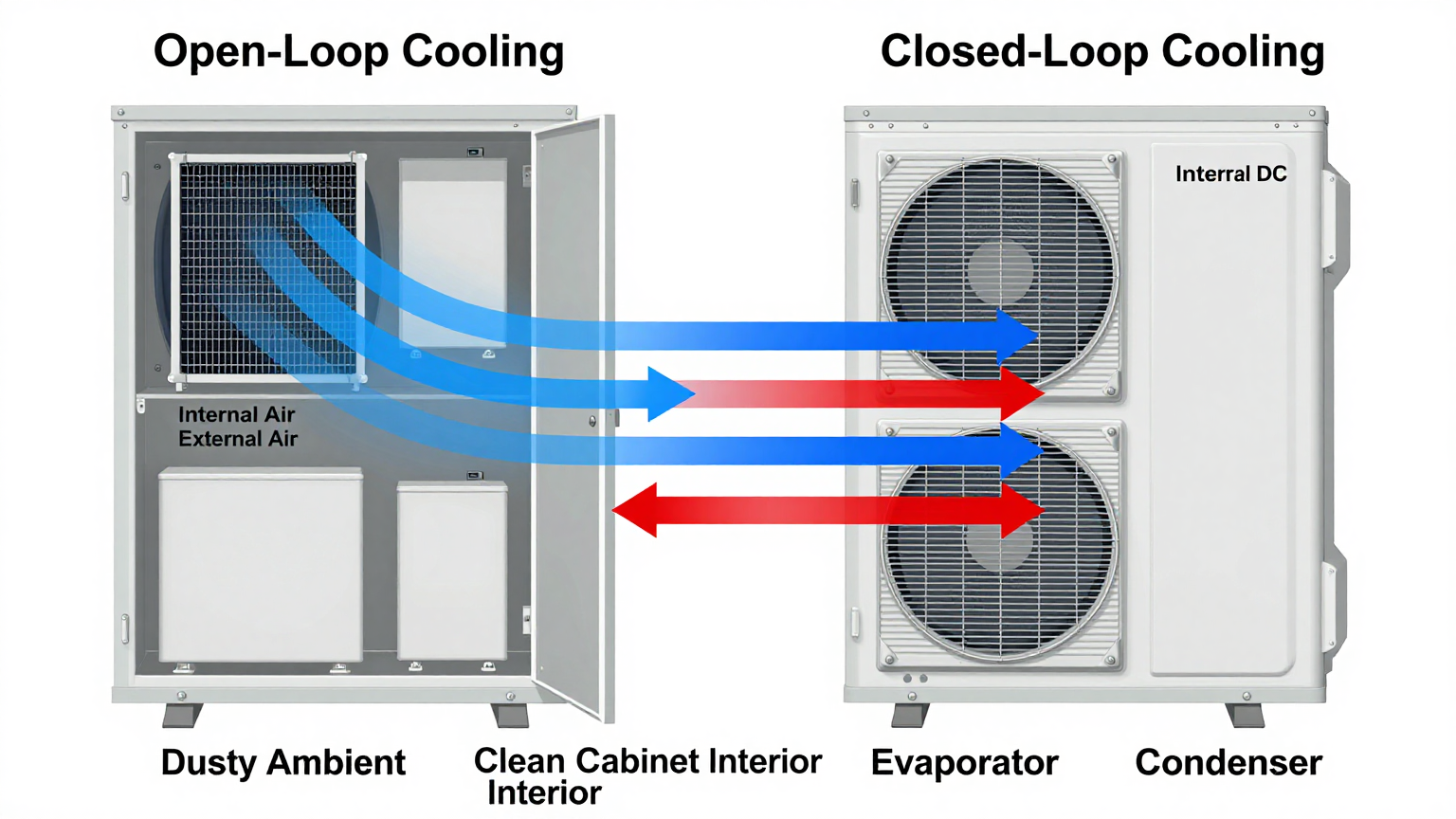

Engineering Fundamentals: Closed-Loop vs. Open-Loop Cooling

The core decision rests on understanding one fundamental concept: the airflow path. A fan-and-filter system is an open-loop design. It operates by pulling ambient factory air into the cabinet, passing it over the hot electronics, and exhausting it. Its effectiveness is forever capped by two constraints: the cleanliness of the ambient air and its temperature. If the air is dirty, the filter is the only line of defense. If the ambient air is already warmer than your target internal temperature, a fan is physically incapable of solving the problem—it can only add more hot air.

A micro dc air conditioner for a dusty factory cabinet, by contrast, is a closed-loop system. It functions like a miniature refrigerator for your enclosure. An internal fan circulates and cools the air already inside the cabinet, never mixing it with the outside environment. The heat is actively removed from this internal air via a vapor-compression refrigeration cycle and exhausted to the outside through a separate, sealed heat exchanger. This creates a clean, controlled internal environment, completely isolated from the dust, humidity, and temperature of the factory floor.

Misconception → Correction: A common misconception is that a more powerful fan or a thicker filter will solve dust-related overheating. This is incorrect. A more powerful fan can actually worsen the problem by increasing the negative pressure inside the cabinet, pulling in even more fine dust through unsealed joints and conduits. A thicker filter may capture more dust, but it also clogs faster and presents a greater impedance to airflow from day one. The correct engineering solution is not to fight the dust with better filters, but to eliminate the pathway for dust ingress entirely with a closed-loop dc enclosure air conditioner in a dusty environment.

Key Specifications for a Micro DC Air Conditioner

When you shift to a closed-loop system, the selection criteria change. It’s no longer about airflow (CFM) alone, but about active heat removal, measured in watts. For a micro dc air conditioner in a dusty factory cabinet, these are the go/no-go specs to confirm with any vendor.

| Model (Series) | Input Voltage | Nominal Cooling Capacity | Refrigerant |

|---|---|---|---|

| DV1910E-AC (Pro) | 12V DC | 450W | R134a |

| DV1920E-AC (Pro) | 24V DC | 450W | R134a |

| DV1930E-AC (Pro) | 48V DC | 450W | R134a |

| DV3220E-AC (Pro) | 24V DC | 550W | R134a |

How to read these specs for our decision:

- Input Voltage: This is a primary filter. The ability to use the cabinet’s native 12V, 24V, or 48V DC bus eliminates the need for a separate AC circuit and bulky AC-DC power supplies, simplifying integration.

- Nominal Cooling Capacity: This is the critical performance metric. It must exceed the total heat load generated by the components inside the cabinet. You must calculate this heat load (in watts) to size the unit correctly.

- Refrigerant: While an important detail for compliance and service, the choice of refrigerant (like R134a) is typically managed by the manufacturer. The key takeaway is that these are true refrigeration systems.

- Physical Dimensions & Weight (Varies by model): The unit must physically fit on or in your enclosure without obstructing access or violating clearance requirements.

- Environmental Sealing (e.g., IP rating): This is non-negotiable. The unit must maintain the enclosure’s sealing rating to be effective. A unit that creates a leak path is no better than a fan filter.

Engineering Selection Matrix: Logic Gates for Integration

Choosing the right thermal solution is a process of elimination based on hard constraints. An engineer must walk through these logic gates to arrive at a reliable and cost-effective solution.

Logic Gate 1: Particulate Contamination Risk

- Constraint Gate: Acceptable level of internal contamination vs. ambient air quality.

- Decision Trigger: If the airborne particulate is conductive (metal dust), abrasive, or corrosive, or if the electronics (VFDs, PLCs, sensitive sensors) are intolerant to any contamination, then an open-loop system is a high-risk choice. If filter replacement intervals are projected to be less than a standard 30-day PM cycle, the maintenance cost becomes prohibitive.

- Engineering Resolution: The requirement for a sealed, clean internal environment mandates a closed-loop cooling approach. This is the first and most important gate that leads directly to considering a micro dc air conditioner for a dusty factory cabinet.

- Integration Trade-off: This path requires a higher initial capital investment compared to a fan/filter unit. However, it drastically reduces the total cost of ownership by virtually eliminating filter replacement costs, cleaning cycles, and downtime caused by contamination-related failures.

Logic Gate 2: Required Internal vs. Maximum Ambient Temperature

- Constraint Gate: The laws of thermodynamics. Heat only moves from a hotter body to a colder one.

- Decision Trigger: Calculate the maximum allowable internal cabinet temperature for all components to operate without derating (e.g., 40°C). Then, measure the worst-case ambient temperature on the factory floor during the hottest time of year (e.g., 45°C). If the required internal temperature is less than or equal to the maximum ambient temperature, no fan, filter, or passive heat exchanger can ever achieve the goal.

- Engineering Resolution: Active cooling via refrigeration is the only viable path. The system must be able to create a temperature differential (Delta T) that overcomes the internal heat load and maintains the setpoint regardless of external conditions. This is the primary function of a Micro DC Aircon.

- Integration Trade-off: The system now consumes more power due to the addition of a compressor. This power draw must be factored into the cabinet’s DC power budget. The benefit is guaranteed thermal performance and predictable electronics reliability.

Logic Gate 3: Power Source and System Footprint

- Constraint Gate: Available power infrastructure and physical space.

- Decision Trigger: If the control cabinet already has a robust 24V or 48V DC power bus with sufficient spare amperage, leveraging it is far more efficient than running a new 120/230V AC line. Furthermore, if the enclosure is compact or space-constrained, a large, side-mounted AC air conditioner may not be feasible.

- Engineering Resolution: Select a compact, native DC-powered unit. A micro dc air conditioner for a dusty factory cabinet, like the 24V DV1920E-AC (Pro) example, is designed for this exact scenario. It integrates directly with the existing power system and has a small form factor suitable for tight installations.

- Integration Trade-off: The DC power supply must be sized to handle the additional load of the air conditioner’s compressor, which can have a higher inrush current on startup. This must be verified to prevent voltage sags that could affect other control components.

Implementation Checklist for a Micro DC Aircon

Proper installation is as critical as proper selection. A perfectly specified unit can be compromised by a poor integration process. Follow this checklist to ensure performance and reliability.

-

Mechanical Integration

- Verify Sealing Surface: Ensure the cabinet mounting surface is flat, clean, and free of deformities. Use the supplied gasket and torque all mounting bolts to the manufacturer’s specification to create a perfect seal. This is the most critical step to prevent dust and moisture ingress.

- Confirm Airflow Paths: Check that the internal and external fans on the unit are unobstructed. Do not mount the cabinet in a way that the hot air exhaust is directed at another heat-sensitive component or back towards the unit’s own condenser intake.

- Condensate Management: If operating in a humid environment, ensure the condensate drain tube is properly routed away from any electronics and is not kinked or blocked.

-

Electrical Connection

- Check Power Budget: Confirm the DC power supply can handle the air conditioner’s maximum rated current draw, not just its nominal draw. Use appropriately gauged wiring to minimize voltage drop.

- Install Overcurrent Protection: Wire the unit through a dedicated, correctly sized fuse or circuit breaker as specified in the installation manual. This protects both the unit and the power supply.

- Control Wiring: If using remote on/off or alarm contacts, ensure the wiring is shielded if routed near high-noise sources like VFD motor leads.

-

Thermal Validation

- Strategic Sensor Placement: Place an independent temperature logger or thermocouple near the most heat-sensitive or highest-power component in the cabinet, typically at the top. Do not place it directly in the air conditioner’s cold air outlet.

- Perform a Load Test: After installation, run the machinery under its typical maximum load on a warm day. Monitor the internal cabinet temperature to confirm it stays well below the preset limit and remains stable.

-

Maintenance Planning

- Scheduled Inspection: While a closed-loop system eliminates filter changes, it doesn’t eliminate all maintenance. Schedule a quarterly or semi-annual check to inspect the external condenser coils. In extremely dusty or oily environments, these may need to be cleaned with compressed air or a suitable solvent to maintain heat transfer efficiency.

- Log Performance: Keep a simple log of the typical internal operating temperature. A gradual increase over time can be an early indicator of a dirty condenser or other system issue.

Frequently Asked Questions (FAQ)

Should I choose a more powerful fan or a micro DC air conditioner for a dusty factory cabinet?

If your primary problem is dust, a more powerful fan will likely make the problem worse by pulling more contaminants into the enclosure through small gaps. If your problem is that the ambient temperature is already too high, a fan cannot help. A micro dc air conditioner for a dusty factory cabinet solves both problems by sealing the enclosure and actively cooling the internal air.

What if my cabinet is already NEMA or IP rated?

A rating only applies to the cabinet as manufactured. When you cut a hole to install a fan and filter, you are creating a potential point of failure. A properly installed closed-loop air conditioner is designed to maintain the enclosure’s rating, using gaskets and sealed construction to ensure integrity.

Will an air conditioner create condensation inside my cabinet?

Properly designed cabinet air conditioners manage condensation as a core function. They cool the internal air, and any moisture that condenses on the evaporator coils is collected and drained to the exterior of the cabinet. This process actually dehumidifies the internal air, protecting electronics.

How does direct sun or proximity to a furnace affect the choice?

Both direct sun (solar load) and radiant heat from nearby equipment add to the total heat load of the cabinet. These are factors that make fan/filter cooling even less effective. You must calculate this external heat load and add it to the internal heat load from your electronics to correctly size an active air conditioning unit.

What is the single most important thing to measure before buying?

The total internal heat load in watts. You can estimate this by summing the power consumption of all components and assuming a percentage is converted to heat (often close to 100% for power supplies and drives). Without an accurate heat load calculation, you cannot correctly size any cooling solution.

How do I validate the cooling performance after installation?

The best method is data logging. Use a temperature logger to record the internal cabinet temperature over a full production cycle on a hot day. Compare this to the maximum operating temperature of your most sensitive component. The temperature should remain stable and well below the critical limit.

Conclusion: The Right Tool for a Hostile Environment

The choice between open-loop and closed-loop cooling is not about which is universally better, but about which is appropriate for the operating environment. In clean, climate-controlled rooms, fan-and-filter systems can be a cost-effective solution. However, in dusty, hot, or humid industrial settings, they represent a false economy, creating a cycle of reactive maintenance, contamination-driven failures, and unpredictable downtime.

A closed-loop, active cooling solution like a micro dc air conditioner for a dusty factory cabinet is the best-fit approach when system reliability is paramount and the ambient environment is hostile. By sealing the enclosure from particulates and actively pumping heat out, it provides a stable, predictable operating environment for critical electronics. This shifts the investment from a recurring operational expense (labor, filters, downtime) to a one-time capital expense that enhances system robustness and lowers the total cost of ownership.

If you are facing challenges with electrical cabinet overheating in dusty or demanding environments, our engineering team can help you accurately calculate your heat load and configure a cooling solution tailored to your specific power, mounting, and environmental constraints.

0 条评论