Angle Lock: The critical decision is choosing between a passive heat exchanger and an active micro DC air conditioner for a sealed outdoor enclosure. The primary failure modes are heat-induced electronics derating and condensation-driven corrosion. The dominant constraint is the combination of high ambient temperatures and rising internal heat loads from 5G and edge computing hardware.

Solving Outdoor Telecom Cabinet Overheating: A Guide to the Micro DC Air Conditioner Telecom Cabinet

A service alert from a remote cell tower or edge computing node is more than an inconvenience; it’s a costly truck roll and a potential service outage. When the cause is thermal failure—sensitive radio equipment or industrial PCs derating or shutting down from extreme heat—the problem becomes systemic. As telecom and edge infrastructure is pushed into harsher environments, traditional cooling methods like fans and filters introduce contaminants, while heat exchangers reach their physical limits. The engineering challenge is no longer just about cooling, but about achieving stable, reliable thermal control within a sealed, protected environment.

By the end of this article, you will be able to identify the specific environmental and thermal thresholds that make an active cooling system necessary. You will have a clear framework for deciding when a micro dc air conditioner telecom cabinet is the correct engineering path to ensure equipment longevity and system uptime. In this analysis, we prioritize long-term reliability and system stability over minimal upfront cost, focusing on the thermal delta limitations that drive the need for active, closed-loop cooling.

Deployment Context: Where Passive Cooling Fails

The need for a more robust thermal solution often becomes apparent after a failure. Consider two common scenarios where legacy cooling methods prove insufficient, leading to the adoption of a micro dc air conditioner telecom cabinet.

Scenario A: The Sun-Baked Rural 5G Repeater

A network provider deployed a series of 5G repeater nodes in sealed cabinets across a desert region. Initially, they relied on heat exchangers to manage the thermal load from the radio units. During the first summer, with ambient temperatures hitting 45°C and intense, direct solar radiation, internal cabinet temperatures consistently exceeded the 55°C operating limit of the electronics. The heat exchanger, only capable of keeping the internal temperature a few degrees above the scorching ambient air, was overwhelmed. This led to intermittent signal drops and forced service calls to reset equipment that had thermally throttled or shut down.

Scenario B: The Urban Rooftop Edge Node

An MSP (Managed Service Provider) installed an edge computing cabinet on a commercial rooftop in a dense urban center to process local IoT data. The cabinet housed several small servers, creating a constant internal heat load of 400W. Due to air quality concerns and wind-driven rain, the enclosure had to be sealed to an IP55 rating, ruling out simple fans. The selected heat exchanger couldn’t cope with the combination of the high internal power density and the solar load on the cabinet’s metal skin, causing CPU throttling on the servers and compromising data processing performance during peak afternoon hours. This is a classic case of failure in edge computing cabinet thermal management.

Common Failure Modes & System Constraints

When designing for remote deployments, anticipating failure is key. The following issues, ranked by impact, are the primary drivers for upgrading to a more robust cooling solution like a micro dc aircon for outdoor telecom enclosure.

- High Internal Temperature → Electronics Derating/Shutdown → Critical service outage, data loss, and direct revenue impact.

- Dust & Moisture Ingress → Corrosion & Short Circuits → Catastrophic hardware failure and voided warranties from using open-loop fan/filter systems.

- High Ambient Temperature → Ineffective Heat Exchangers → Inability to maintain a safe thermal delta, as passive units cannot cool below ambient.

- Condensation from Temperature Swings → Water Damage → Unmanaged moisture from improper cooling cycles can pool and destroy sensitive PCBs.

- High Solar Load → Elevated Internal Ambient → The cabinet skin absorbs solar energy, adding a significant heat load that passive solutions struggle to reject.

- Increasing Heat Density → Component Proximity Overheating → As more powerful electronics are packed into smaller cabinets, passive air circulation is insufficient.

- Limited DC Power Budget → Inefficient Cooling → An oversized or inefficient cooler can drain backup battery systems prematurely during a power outage.

- Difficult Service Access → High OPEX → Systems requiring frequent filter changes or cleaning increase the total cost of ownership significantly.

Engineering Fundamentals: Closed-Loop Cooling vs. Heat Exchange

To make the right selection, it’s crucial to understand the fundamental difference between moving heat and simply moving air. The core of effective outdoor telecom cabinet overheating prevention lies in creating a closed-loop environment.

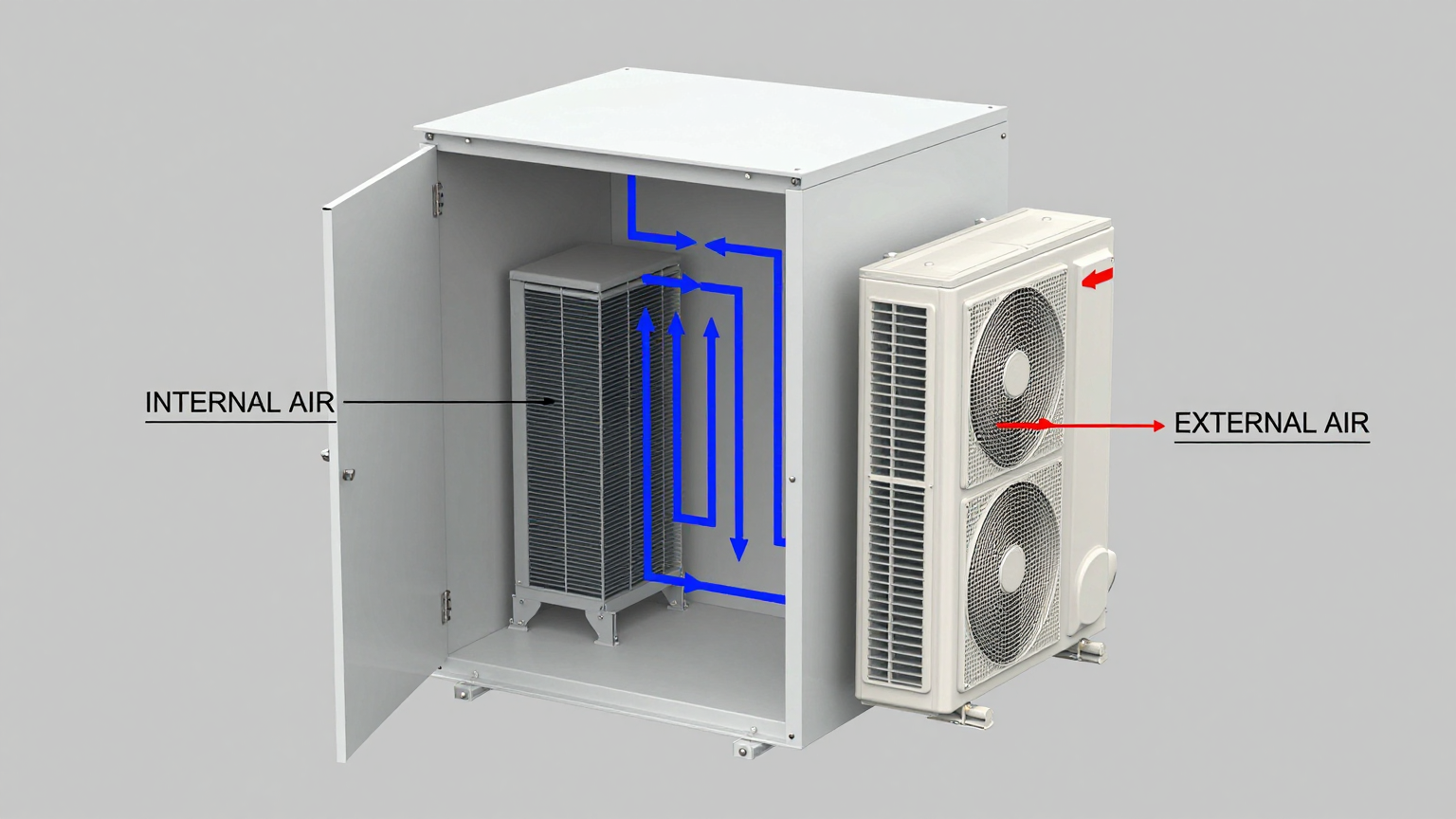

A micro dc air conditioner telecom cabinet operates on this principle. It establishes two completely separate air circuits. The internal circuit pulls warm, humid air from inside the cabinet, passes it over a cold evaporator coil to remove heat and moisture, and returns cool, dry air back into the cabinet. The captured heat is transferred via refrigerant to an external condenser coil, where a second, separate fan dissipates it into the outside environment. This design ensures that no dust, humidity, or corrosive elements from the outside ever enter the sealed enclosure, preserving the integrity of the electronics.

A common misconception is that a heat exchanger also provides a closed loop. While it does use two separate air streams, its mechanism is entirely different and has a critical limitation. A heat exchanger can only transfer heat from the warmer internal air to the cooler external air. This means it is unlikely to meet the requirement for a heat exchanger to cool the inside of the cabinet to a temperature at or below the outside ambient temperature. Once the outside air gets too hot, the heat exchanger loses its effectiveness.

The correction is to shift focus from airflow volume (CFM) to heat removal capacity (watts or BTU/hr). A vapor-compression system, like a Micro DC Aircon, actively removes a specific amount of heat energy from the cabinet, allowing it to achieve an internal temperature that is significantly lower than the ambient outdoor temperature—a capability known as sub-ambient cooling.

Specification Gateway for Active Cooling Units

When evaluating a micro dc air conditioner telecom cabinet, a few core specifications serve as the primary go/no-go gates for a project. The decision hinges on matching the available DC bus voltage and ensuring the nominal cooling capacity sufficiently exceeds the cabinet’s total calculated heat load (internal electronics + external solar gain). Below are examples from the Micro DC Aircon series.

| Example Model | DC Voltage | Nominal Cooling Capacity | Refrigerant |

|---|---|---|---|

| DV1920E-AC (Pro) | 24V | 450W | R134a |

| DV1930E-AC (Pro) | 48V | 450W | R134a |

| DV3220E-AC (Pro) | 24V | 550W | R134a |

Note: These are representative models. Final selection depends on a full thermal audit. Cooling capacity can vary based on operating conditions.

Engineering Selection Matrix: Logic Gates for Integration

An engineer must pass through several logic gates to arrive at the correct thermal solution. This process moves beyond simple spec sheets to address the hard constraints of industrial integration.

Logic Gate 1: The Thermal Delta Requirement

- Constraint Gate: Required Internal Temperature vs. Maximum External Ambient Temperature.

- Decision Trigger: If the required internal cabinet temperature must be maintained at or below the peak external ambient temperature (e.g., internal must stay at 40°C when it’s 45°C outside).

- Engineering Resolution: A heat exchanger is unlikely to meet the requirement of meeting this requirement. The selection path must shift to an active vapor-compression system. This is the clearest dividing line in the micro dc aircon vs heat exchanger telecom debate.

- Integration Trade-off: This choice increases the DC bus load and upfront capital cost but is often the one of the most practical ways to help maintain zero-derating of the enclosed electronics in hot climates.

Logic Gate 2: The Environmental Sealing Mandate

- Constraint Gate: Required IP/NEMA rating vs. Environmental Contaminants.

- Decision Trigger: If the deployment is in an environment with high levels of dust, salt spray, humidity, or wind-driven rain that mandates a sealed enclosure (e.g., IP55 or higher).

- Engineering Resolution: Open-loop solutions like fans and filters are often rules out. The choice narrows to a heat exchanger or a dc enclosure air conditioner for edge cabinet. The final decision then typically reverts to the thermal delta analysis in Logic Gate 1.

- Integration Trade-off: Requires disciplined mechanical integration. The installer must ensure the mounting cutout and gasket surfaces are properly prepared to maintain the enclosure’s seal integrity.

Logic Gate 3: The Heat Load Density Threshold

- Constraint Gate: Internal Heat Load (Watts) vs. Cabinet Surface Area.

- Decision Trigger: When the power density of the internal electronics (e.g., edge servers, 5G radios) generates heat faster than it can be passively dissipated through the cabinet’s walls, even with a heat exchanger’s assistance. A common threshold is when internal loads exceed 200-300W in a compact enclosure.

- Engineering Resolution: The high thermal load demands the superior heat removal capacity (measured in watts) of a refrigerant-based system. A micro dc air conditioner telecom cabinet can remove hundreds of watts of heat energy efficiently.

- Integration Trade-off: The air conditioner requires a dedicated circuit on the DC power bus and careful consideration of its placement to optimize internal air circulation and avoid hot spots.

Implementation & Verification Checklist

Proper installation is as critical as proper selection. A mistake during integration can compromise the entire system. Follow this checklist for a successful deployment.

-

Mechanical Integration

- Verify the mounting cutout on the cabinet matches the unit’s template precisely.

- Ensure the mounting surface is flat, clean, and free of burrs to allow the gasket to create a continuous seal.

- Confirm that both the internal (cold air) and external (hot air) airflow paths are completely unobstructed by cables, components, or nearby walls.

-

Electrical Integration

- Connect the unit to the correct, stable DC voltage bus (typically 24V or 48V in telecom). An incorrect voltage will damage the controller.

- Use the recommended wire gauge to handle the current draw, especially during compressor startup.

- Install the specified in-line fuse or circuit breaker as close to the power source as possible for overcurrent protection.

-

Thermal Validation

- Place independent temperature sensors near the air intake of the most sensitive electronic components, not directly in the cooling unit’s output stream.

- Conduct a full-load system test (or use a dummy heat load) on a warm day to verify that the internal temperature stabilizes at the desired setpoint.

- Check that the condensation management system (e.g., drain tube) is properly routed away from any connections and is not clogged.

-

Long-Term Maintenance

- Schedule biannual inspections of the external condenser coils and fans to check for blockages from dust, leaves, or other debris.

- During inspection, verify the integrity of the cabinet’s door and panel gaskets.

- Review system logs, if available, for any thermal alarms or unusual temperature fluctuations.

Frequently Asked Questions (FAQ)

When should I choose a micro DC aircon vs. a heat exchanger for my telecom cabinet?

Choose a micro DC air conditioner when you need the internal temperature to be at or below the outside ambient temperature, or when the total heat load (electronics + solar) is too high for a heat exchanger to manage effectively. If a 10°C rise above ambient is acceptable and your heat load is low, a heat exchanger may suffice.

How does a micro DC air conditioner affect a sealed IP/NEMA rating?

These units are specifically designed for sealed enclosures. When installed correctly using the provided gasket on a smooth, flat surface, a micro dc air conditioner telecom cabinet maintains and integrates with the enclosure’s IP/NEMA rating, preventing dust and water ingress.

Will this unit cause condensation inside my cabinet?

Because it is a closed-loop system, it only cools and dehumidifies the air already inside the cabinet. Condensation forms on the internal evaporator coil, where it is collected and typically managed through an integrated drain port, keeping it away from your electronics.

How does direct sunlight affect performance?

Direct sunlight (solar load) adds a significant amount of heat to the cabinet, which the air conditioner must also remove. This load must be calculated and added to your electronics’ heat load when sizing the unit. Using a solar shield above the cabinet or painting the cabinet a light, reflective color can significantly reduce this effect.

What are the first things I need to measure before selecting a cooling unit?

You must determine four key values: 1) The total internal heat load from your electronics in watts. 2) The maximum expected ambient temperature at the deployment site. 3) The maximum allowable internal temperature for your components. 4) The available DC voltage (12V, 24V, 48V) and power budget in amps.

How do I validate the cooling performance after installation?

The best practice is to monitor the case temperature of your most critical components (e.g., CPU, radio transmitter) under full operational load during the hottest part of the day. This provides a much more accurate picture of thermal stability than simply measuring the ambient air inside the cabinet.

What is the power consumption of a micro dc air conditioner telecom cabinet?

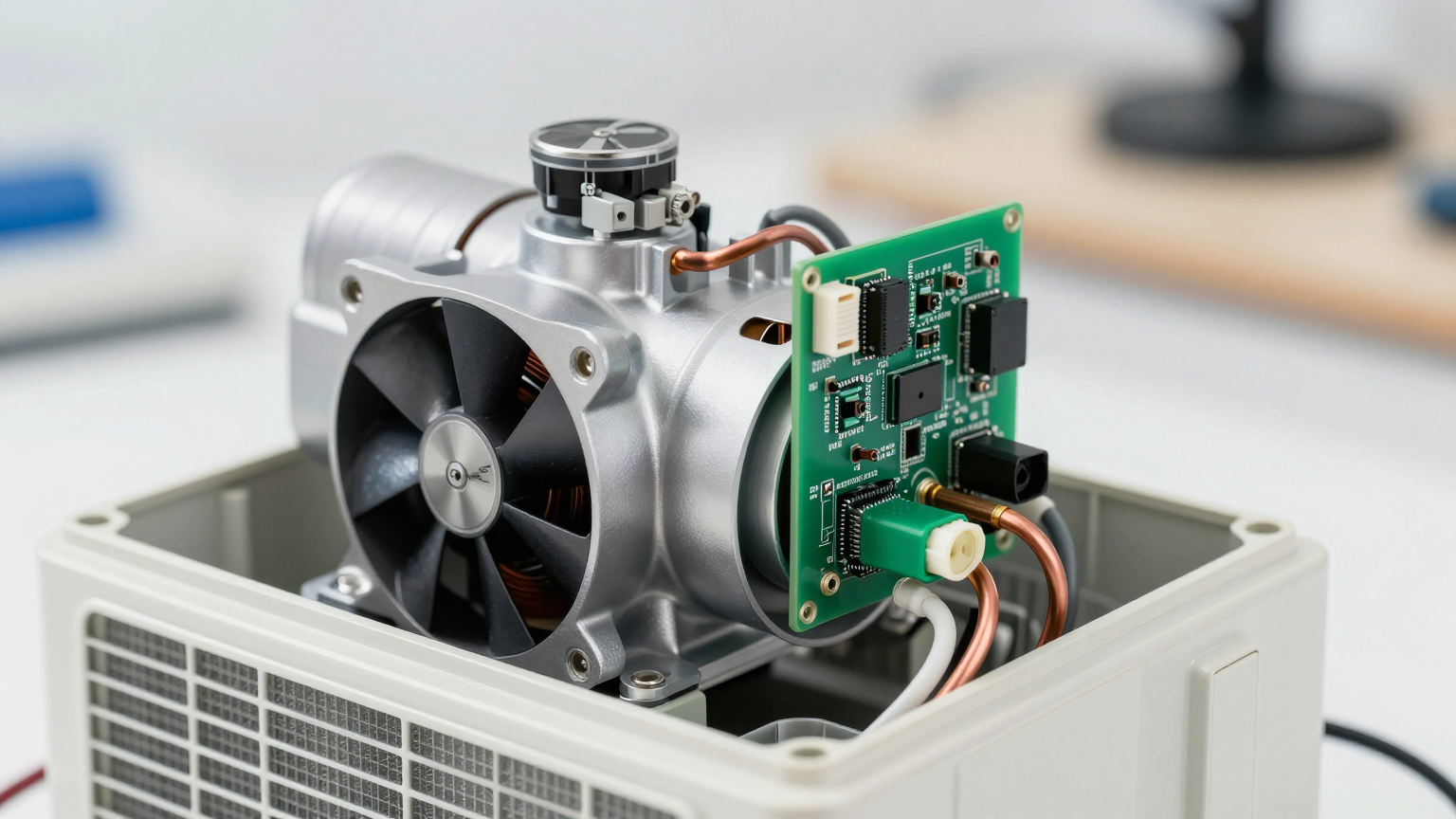

Power consumption varies by model and cooling load. Modern units use variable-speed BLDC compressors and inverter technology. This allows the unit to ramp its speed up or down to match the real-time heat load, which is far more energy-efficient than older, fixed-speed on/off systems.

Conclusion: The Right Tool for a Demanding Environment

The decision to use a micro dc air conditioner telecom cabinet is an engineering conclusion driven by data and environmental reality. It is the best-fit solution for sealed enclosures deployed in high ambient temperatures, locations with significant solar load, or cabinets with a rising internal heat density from powerful edge hardware. For these applications, its ability to provide sub-ambient, closed-loop cooling is not a luxury but a requirement for ensuring the uptime and longevity of critical infrastructure. Conversely, for enclosures with very low heat loads in mild climates where a temperature rise above ambient is acceptable, a simpler solution may be adequate.

Ultimately, effective thermal management is about mitigating risk. By moving from a passive to an active cooling strategy, system integrators and OEM engineers can deliver a more resilient, reliable product that performs under pressure and reduces costly service calls. For assistance with thermal load calculations or selecting a cooling solution for a unique enclosure geometry or harsh environment, we recommend consulting with thermal specialists. Explore our solutions for telecom components cooling to learn more.

0 条评论