Angle Lock: The critical decision is choosing between simple ventilation and a closed-loop active cooling system for a DC fast charger. The most common failure modes are thermal derating on hot, sunny days and premature component failure from dust and moisture ingress. The dominant constraint is the non-negotiable need to maintain a sealed enclosure for reliability in outdoor environments.

Solving Derating with a Micro DC Air Conditioner for EV Charger Cabinets

An electric vehicle fast-charging station represents a significant capital investment, with return on investment directly tied to uptime and performance. Yet, a common and costly failure point is often overlooked in the initial design phase: thermal management. When a DC fast charger in a busy commercial lot begins to derate—throttling charging speed to a crawl on a hot afternoon—it’s not just an inconvenience. It’s a direct loss of revenue, a blow to customer confidence, and a symptom of an impending component failure. The power electronics at the heart of these systems generate immense waste heat, and when trapped in a sealed cabinet under direct solar load, temperatures can quickly exceed critical thresholds.

Simply moving air with a fan is a solution that works only in the most forgiving conditions. For the high-reliability, all-weather deployments expected of public charging infrastructure, a more robust strategy is required. By the end of this technical analysis, you will be able to determine the precise threshold at which active, refrigerated cooling becomes an engineering necessity. In this article, we prioritize long-term system reliability and return on investment over minimal upfront component cost, analyzing why traditional cooling methods are often insufficient for high-power, sealed outdoor electronics enclosures. The focus will be on selecting the right micro dc air conditioner for an EV charger cabinet based on specific environmental and operational triggers.

Deployment Context: Where Simple Cooling Fails

The gap between theoretical and real-world performance often appears in the field, where environmental variables expose design weaknesses. Two common scenarios illustrate this challenge for EV charger cabinet thermal management.

Scenario A: Urban Fast-Charging Hub

Consider a bank of 150kW DC fast chargers installed in a retail parking lot in a warm climate. The initial design incorporated high-CFM filtered fans to keep costs down. For the first few months in spring, the system performed to specification. However, during the first major summer heatwave, with ambient temperatures hitting 38°C (100°F), performance plummeted. By 2 PM, with peak solar load on the dark-colored cabinets, internal temperatures soared past 60°C. The power modules began to derate to protect themselves, slashing charging speeds by over 50%. The root cause was twofold: the ambient air was too hot to provide meaningful cooling, and the filters were already becoming clogged with airborne dust and pollen, restricting airflow and compounding the problem.

Scenario B: Industrial Fleet Charging Depot

An operator of a commercial electric delivery fleet installed a series of chargers in an outdoor depot. The environment contains significant industrial dust and is subject to periodic high-pressure wash-downs, mandating a NEMA 4 (IP66) sealed enclosure. The engineering team initially specified a large air-to-air heat exchanger, a passive, closed-loop solution. The problem arose from the sheer heat density. The power conversion systems generated over 2,500 watts of waste heat in a compact cabinet. A heat exchanger’s effectiveness is entirely dependent on the temperature difference between the internal and external air. On a moderately warm day, there wasn’t a large enough thermal gradient for the exchanger to reject heat effectively, leading to a slow but steady rise in internal temperature and eventual over-temperature faults.

Common Failure Modes and System Constraints

Understanding the symptoms of poor thermal management is key to diagnosing the root cause. For EV charger cabinets, these issues typically cascade from minor performance dips to catastrophic failures.

- Symptom: Charging session speed drops significantly after 15-20 minutes. → Cause: Power electronics exceed their thermal threshold and automatically derate output current. → Impact: Poor user experience, reduced throughput, and direct loss of revenue per session.

- Symptom: The charger’s management system logs frequent “over-temperature” alerts. → Cause: The cooling system lacks the capacity to handle the combined internal heat load, ambient temperature, and solar gain. → Impact: The system may shut down entirely, requiring a manual reset and causing costly downtime.

- Symptom: A fine layer of dust and grime is found on internal components during service. → Cause: A vented or fan-cooled enclosure is allowing contaminant ingress. → Impact: Increased risk of short circuits, premature fan bearing failure, and reduced lifespan of sensitive electronics.

- Symptom: Visible condensation or corrosion on circuit boards. → Cause: Humid ambient air is drawn into the cabinet by fans and cools below its dew point. → Impact: High risk of immediate electrical failure and long-term reliability issues.

- Symptom: Cooling fans run constantly at maximum speed, but internal temperatures continue to climb. → Cause: The external air temperature is too close to the maximum operating temperature of the electronics, leaving no effective thermal gradient for heat exchange. → Impact: The cooling system is consuming power but achieving nothing, with thermal derating imminent.

- Symptom: Power modules or DC-DC converters fail years ahead of their expected service life. → Cause: Sustained operation at elevated temperatures dramatically accelerates the aging of electronic components, especially capacitors. → Impact: Increased maintenance costs, frequent service calls, and a lower return on investment for the charging asset.

Engineering Fundamentals: Closed-Loop vs. Open-Loop Cooling

The core decision in charger cabinet thermal management (sealed) hinges on one concept: the integrity of the enclosure. An open-loop system, like a fan with a filter, exchanges air between the inside of the cabinet and the outside world. A closed-loop system isolates the internal air, recirculating and cooling it without introducing outside contaminants.

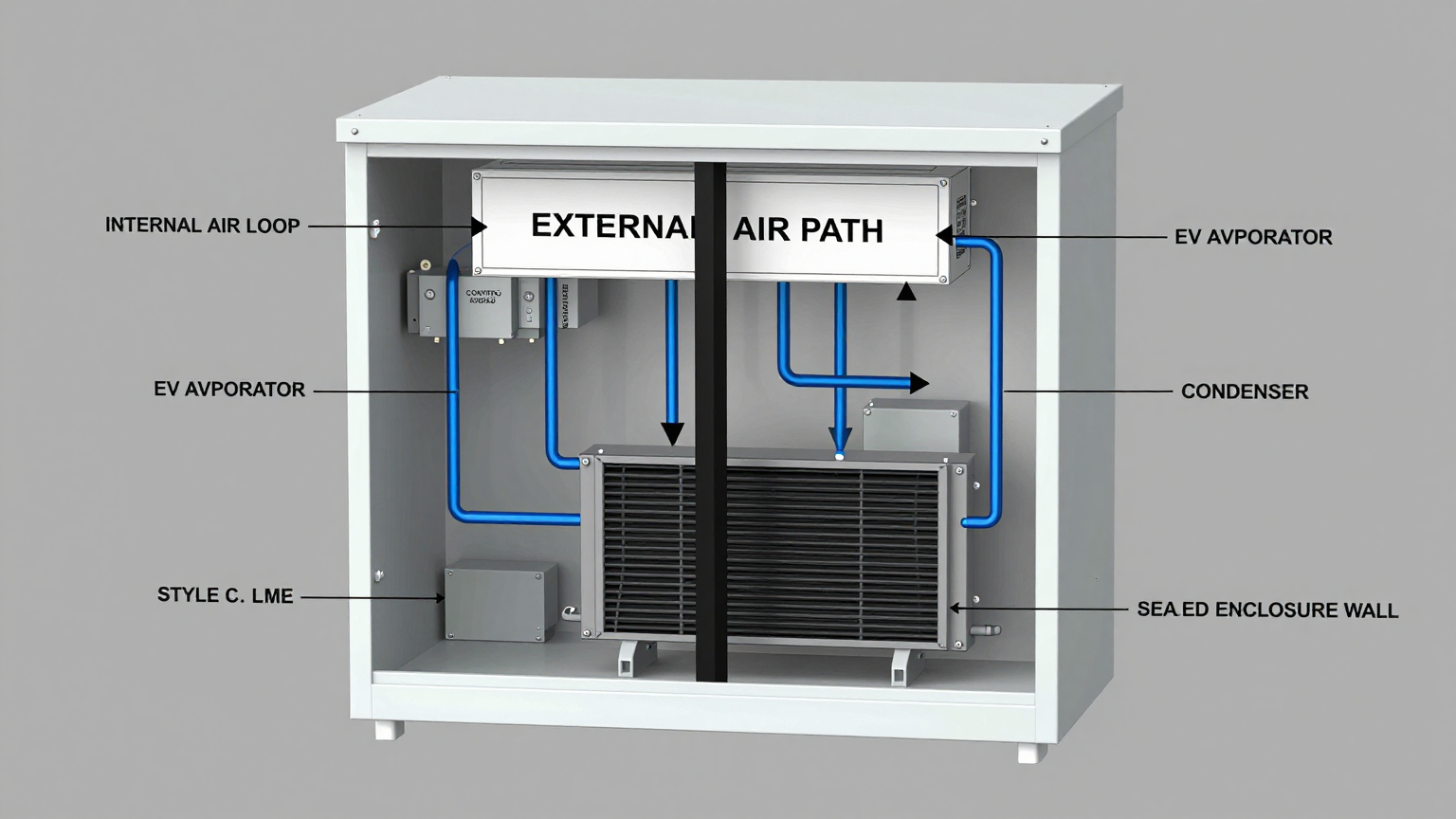

A micro dc air conditioner for an EV charger cabinet is a true closed-loop system. It operates on a vapor-compression refrigeration cycle, functioning as a heat pump. It has two separate air paths:

- Internal Loop (Evaporator): A fan draws hot air from inside the sealed cabinet across the cold evaporator coil. Heat is absorbed from the air into the refrigerant, and the now-cool, dehumidified air is sent back into the cabinet.

- External Loop (Condenser): The refrigerant, now a hot gas carrying the heat from inside, is pumped to the condenser coil on the outside of the unit. An external fan blows ambient air across the condenser, transferring the heat from the refrigerant to the outside world.

This mechanism physically separates the internal and external environments, allowing the cabinet to remain sealed and maintain its IP or NEMA rating. This is the only way to protect sensitive electronics from rain, dust, humidity, and corrosive salt fog.

The Critical Misconception: Fans vs. Air Conditioners

A common but flawed assumption is that if a cabinet is overheating, a more powerful fan will solve the problem. This is incorrect. A fan cannot cool the air below the ambient temperature. If it is 40°C outside, a fan can only ever move 40°C air into the cabinet. For high-power electronics that need to be kept at or below that temperature, a fan is functionally useless. An active refrigeration system, like a micro DC air conditioner, is the only technology that can create an internal environment cooler than the outside world.

Key Specifications for a Micro DC Air Conditioner

When evaluating a micro dc air conditioner for an EV charger cabinet, several specifications are critical go/no-go gates. The selection process must be driven by data, not assumptions. The table below shows baseline parameters for our Micro DC Aircon series, which are designed for these compact, high-value electronic enclosures.

| Parameter | Specification Range / Options | Importance for EV Charger Cabinets |

|---|---|---|

| DC Voltage | 12V / 24V / 48V | Must match the available auxiliary DC power bus within the charger cabinet. 48V is common in telecom-grade power systems. |

| Nominal Cooling Capacity | 100W – 900W | The single most important spec. Must exceed the total waste heat generated by all internal components, plus solar load, with a safety margin. |

| Refrigerant | R134a / R290 / R1234yf | Determines thermodynamic performance and environmental compliance. R134a is a standard, while others offer lower GWP. |

| Control System | Integrated PCB with variable-speed control | Inverter-driven compressors and fans modulate performance to match the real-time heat load, saving energy and reducing component stress. |

| Example Model (24V) | DV1920E-AC (Pro) | Provides 450W of nominal cooling, suitable for many compact DC fast charger power cores. |

| Example Model (48V) | DV1930E-AC (Pro) | Offers 450W of cooling on a 48V DC bus, aligning with common power architectures. |

To read these specs for your decision, start with the heat load. Calculate the total watts of heat your electronics produce (typically 5-10% of the charger’s rated power). Add a solar load calculation (often 200-300W for a cabinet in direct sun). The chosen unit’s cooling capacity must comfortably exceed this total. Then, confirm the available DC voltage to ensure compatibility.

Engineering Selection Matrix: Logic Gates for Thermal Design

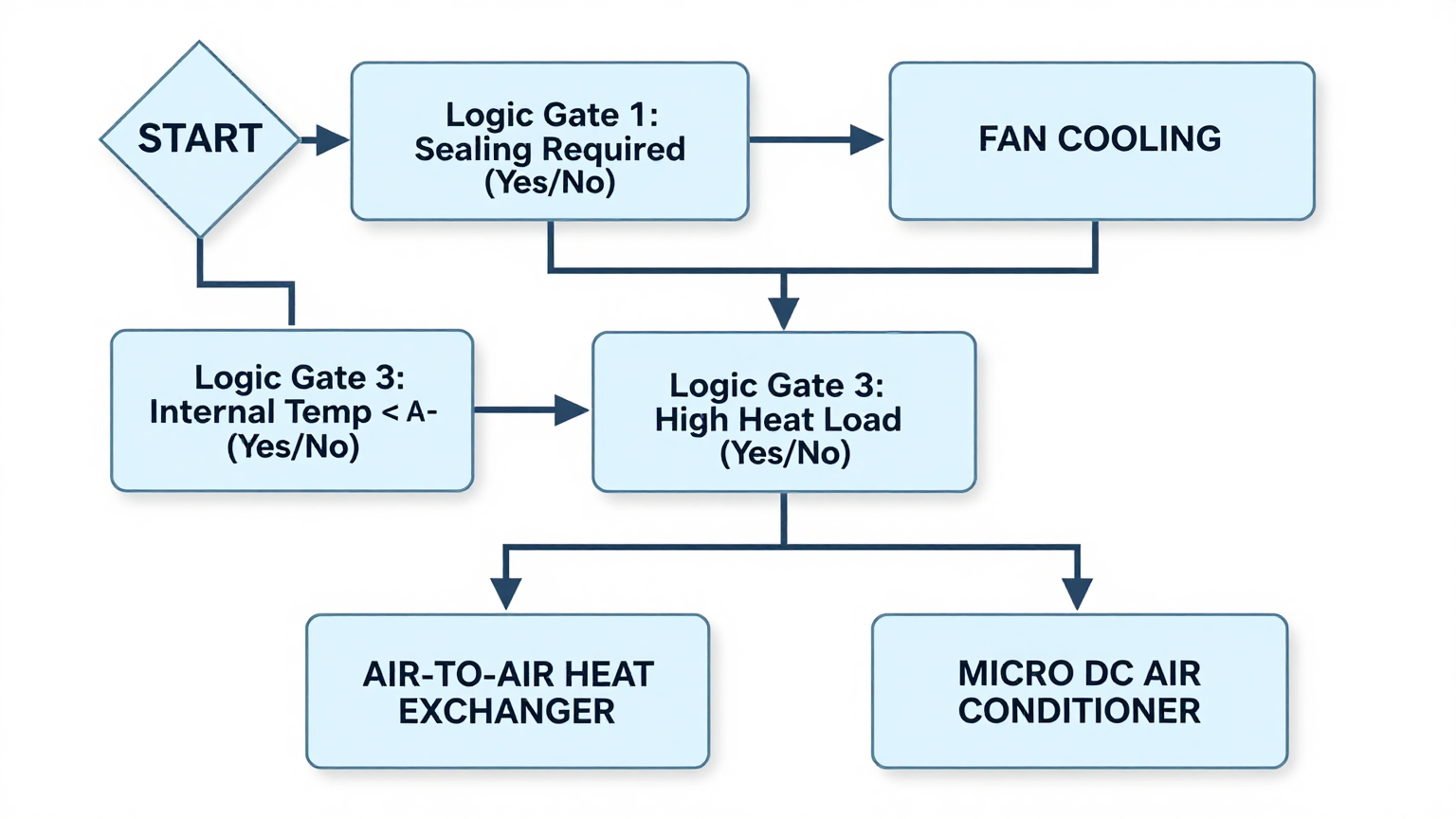

An engineer must pass through several logic gates to arrive at the correct thermal solution. This process systematically eliminates options that cannot meet the project’s core constraints.

Logic Gate 1: The Sealing Requirement

- Constraint Gate: Is a sealed enclosure (e.g., IP55, NEMA 4, or higher) required to protect internal electronics from water, dust, or corrosive elements? For any outdoor charger, the answer is almost universally yes.

- Decision Trigger: If the enclosure must be sealed.

- Engineering Resolution: This decision immediately disqualifies any open-loop cooling solution, such as simple filtered fans. The choice is now narrowed to closed-loop systems: a passive air-to-air heat exchanger or an active dc enclosure air conditioner for a charger cabinet.

- Integration Trade-off: This path requires disciplined mechanical design, including high-quality gaskets and sealed cable glands, but it is the foundation of a reliable product.

Logic Gate 2: The Thermal Delta Requirement

- Constraint Gate: Can the internal cabinet temperature be allowed to rise above the maximum external ambient temperature?

- Decision Trigger: If the maximum allowable internal temperature for the electronics (e.g., 45°C) is close to, equal to, or lower than the maximum possible external temperature on a hot day with solar load (e.g., 50°C).

- Engineering Resolution: This trigger disqualifies a passive heat exchanger. A heat exchanger can only move heat from a hotter space to a cooler space. If the outside is not significantly cooler than the desired inside temperature, it ceases to function. This leaves an active, refrigerated micro dc air conditioner for an EV charger cabinet as the most viable path.

- Integration Trade-off: The air conditioner adds a load to the DC power bus, which must be accounted for in the system’s power budget. However, it provides deterministic cooling, guaranteeing the target internal temperature regardless of external conditions (within its operating range).

Logic Gate 3: The Heat Load Density Calculation

- Constraint Gate: What is the total waste heat (in watts) generated by the power modules, rectifiers, controllers, and other components inside the cabinet at full load?

- Decision Trigger: If this calculated heat load, plus solar gain, exceeds the capacity of a reasonably sized passive solution. For DC fast chargers, where waste heat is often 1,500W to 3,000W, this threshold is always crossed.

- Engineering Resolution: The nominal cooling capacity of the selected micro dc air conditioner for the EV charger cabinet must be greater than the total calculated heat load. A safety margin of at least 20-25% is recommended to account for component aging and higher-than-expected ambient conditions.

- Integration Trade-off: A higher capacity cooling unit may have a larger physical footprint and higher peak power draw. The cabinet’s mechanical design must accommodate the unit’s dimensions and ensure unobstructed airflow for both the internal (cold) and external (hot) loops.

Implementation and Verification Checklist

Proper installation is as critical as proper selection. A correctly chosen unit can be compromised by a poor mechanical or electrical installation.

-

Mechanical Integration

- Mounting: Securely fasten the unit to the cabinet wall using all specified mounting points. Ensure the orientation (vertical/horizontal) matches the manufacturer’s guidelines to ensure proper condensate management.

- Sealing: The gasket between the air conditioner and the cabinet exterior is the most critical sealing surface. Ensure the surface is clean, flat, and the gasket is compressed evenly to maintain the enclosure’s IP/NEMA rating.

- Airflow Integrity: Internally, ensure that racks, cables, or components do not block the cold air outlet or the return air inlet. Externally, ensure the hot air exhaust is not blocked or positioned where it could be drawn back into the condenser intake or heat up adjacent equipment.

-

Electrical Integration

- Power Connection: Connect the unit to the specified DC voltage bus (12V, 24V, or 48V). Use wiring of the appropriate gauge to handle the maximum current draw without voltage drop.

- Circuit Protection: The DC supply line to the air conditioner must be protected by a correctly rated fuse or circuit breaker as specified in the installation manual.

- Control Wiring: If using features like a remote thermostat or alarm contacts, ensure these low-voltage signal wires are routed away from high-power AC/DC cables to prevent interference.

-

Thermal Validation

- Sensor Placement: For acceptance testing, place thermocouples near the air intake of the most heat-sensitive components (e.g., the power modules) and another at the air conditioner’s cold air outlet to measure the temperature drop.

- Load Testing: The ultimate test. Operate the EV charger at its maximum continuous power output on a warm day (or in a thermal chamber). Monitor the internal cabinet temperature to ensure it stabilizes at or below the target setpoint and does not trigger any derating or thermal alarms.

Frequently Asked Questions (FAQ)

Should I use a fan or a micro DC air conditioner for my EV charger cabinet?

If the cabinet must be sealed against the elements (IP55+) or if the maximum ambient temperature plus solar gain is close to or exceeds the maximum allowable internal temperature, a micro DC air conditioner is the appropriate engineering choice. A fan is only suitable for non-sealed cabinets in very mild climates with low heat loads.

What if my cabinet is already sealed to IP65? How do I cool it?

This is the ideal scenario for a closed-loop cooling system. A micro dc air conditioner for an EV charger cabinet is designed to be mounted onto a sealed enclosure, maintaining the seal while actively removing internal heat.

Will a DC air conditioner cause condensation inside my cabinet?

No, when installed correctly. It cools and recirculates the same dry, sealed air inside the cabinet. It does not introduce new, humid air from the outside, which is the cause of condensation in fan-cooled systems. Any condensation that forms on the unit’s cold internal coil is managed and drained to the outside.

How does direct sunlight affect cooling performance?

Direct solar radiation (solar load) adds a significant amount of heat to the cabinet, acting as another heat source the cooling unit must overcome. This must be factored into your total heat load calculation. Using a light-colored cabinet or a solar shield can help, but the cooling system must be sized for the worst-case scenario: peak ambient temperature + full solar load + maximum internal heat generation.

What are the first things I must measure before selecting a cooling unit?

You need four key pieces of data: 1) The total internal heat load from your electronics in watts. 2) The maximum expected ambient temperature at the deployment site. 3) The required maximum internal operating temperature to prevent derating. 4) The available DC voltage (e.g., 24V or 48V) and current budget.

How can I validate that the cooling is working correctly after installation?

The best method is empirical load testing. Run the charger at 100% capacity for an extended period on a warm day. Use a thermal logger or IR camera to monitor the temperature of the critical power components. The temperature should rise and then stabilize at a safe level well below the derating threshold.

Conclusion: Matching the Solution to the Stakes

For low-power electronics in forgiving environments, simple fan cooling can be adequate. However, for high-value, revenue-generating assets like DC fast chargers that are expected to perform reliably for years in harsh outdoor conditions, the thermal management strategy must be equally robust. The decision to use a micro dc air conditioner for an EV charger cabinet is made when system uptime is paramount, the enclosure must remain sealed, and the combined ambient and internal heat loads make passive solutions ineffective.

While the initial investment is higher than for a fan, it prevents the far greater costs associated with thermal derating, customer dissatisfaction, premature component failure, and emergency service calls. It is an investment in the reliability and profitability of the charging asset. Sizing a thermal management system requires a precise calculation of heat loads and a clear understanding of environmental constraints. If you are designing an EV charging system and facing these challenges, our engineering team can help analyze your requirements to specify a solution that matches your cabinet geometry, power budget, and deployment environment.

0 条评论