In the realm of remote infrastructure, the thermal management of outdoor enclosures is often the single point of failure for critical systems. For OEM engineers and system integrators, the challenge is rarely just “cooling”; it is cooling within a matrix of hostile constraints. You are battling high ambient temperatures, aggressive solar loading, strict power budgets, and the imperative to seal sensitive electronics against dust, salt, and humidity. While passive ventilation or simple fans are the default choice for cost reasons, they frequently fail to protect equipment once the physics of the environment takes over.

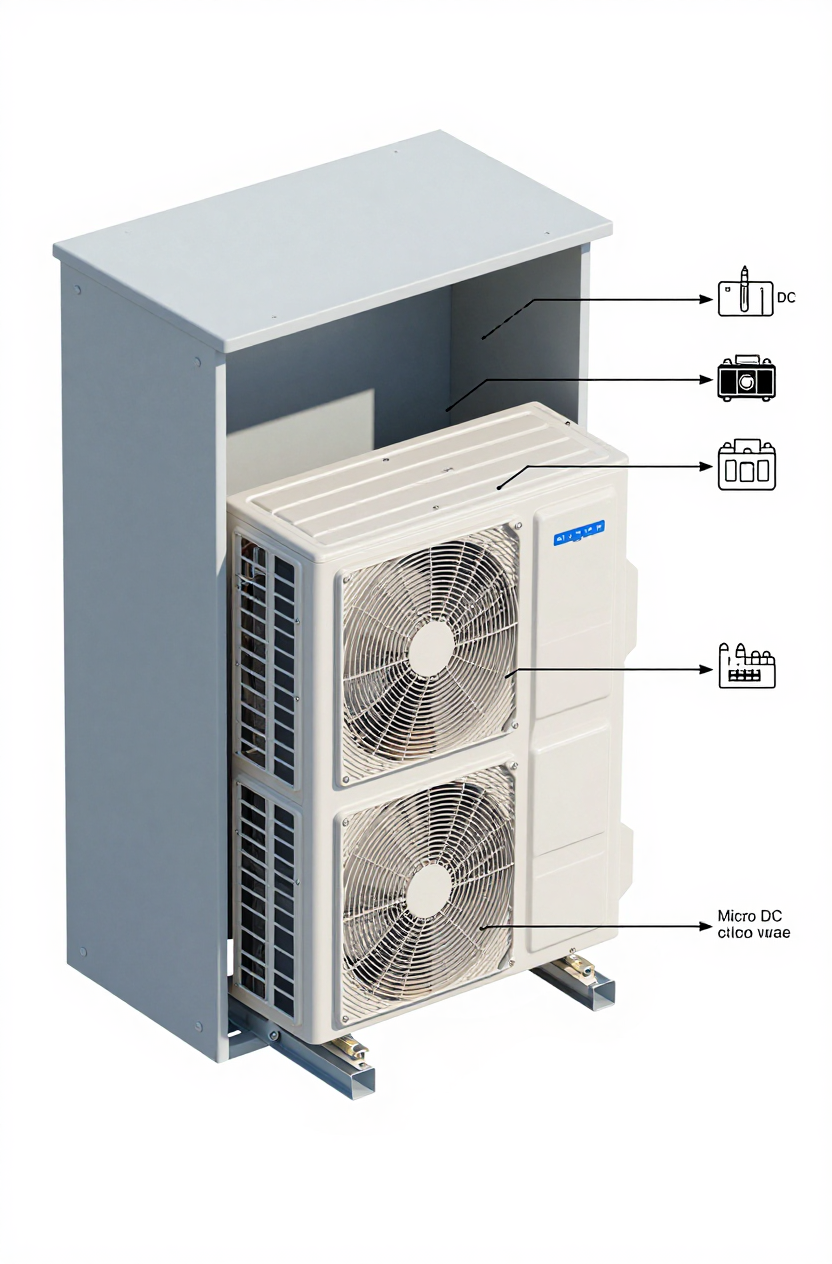

This article examines the engineering logic behind moving from open-loop cooling to closed-loop active cooling, specifically focusing on integrating a micro ac for outdoor electrical cabinet applications. We will strip away the marketing hype to look at the thermal dynamics, the limitations of ambient air exchange, and the specific sizing criteria required to maintain uptime in harsh, off-grid, or mobile deployments.

The decision to upgrade to active cooling is not merely about lowering temperature; it is about decoupling the internal environment from the external chaos. Whether you are deploying telecom repeaters in the Nevada desert or sensor nodes on an offshore rig, the fundamental requirement remains the same: rejecting internal heat while maintaining a hermetic seal.

Deployment Context: Where Passive Cooling Fails

To understand the necessity of active cooling, we must first look at the scenarios where passive methods hit their physical limits. In many deployments, the external environment is not just a boundary condition; it is an active aggressor.

Scenario A: The Desert Telecom Repeater

Consider a remote telecom cabinet situated in a high-insolation environment. The ambient air temperature may peak at 45°C (113°F). However, the solar load—direct sunlight striking the cabinet surface—can add a significant thermal burden, effectively raising the “equivalent” ambient temperature the cabinet skin experiences. If the internal electronics have a maximum operating limit of 50°C, the Delta T (temperature difference) available for heat rejection is negligible. In this context, an open-loop fan system would simply pull in hot, dusty air, accelerating component failure. The system requires sub-ambient cooling to keep internal components below the critical threshold, a feat impossible for fans.

Scenario B: The Coastal Sensor Node

In maritime or coastal applications, the primary threat is not just heat, but corrosion. Salt spray and high humidity can destroy exposed PCBs within months. A standard vented cabinet, even with filtration, allows moisture and saline air to circulate over components. To achieve a NEMA 4X or IP65 rating, the enclosure must be fully sealed. Once sealed, however, heat is trapped. The enclosure walls alone cannot dissipate the heat generated by high-density processors or power supplies. Here, a closed-loop cooling solution is mandatory to recirculate internal air while rejecting heat to the outside, without ever opening the loop to contaminants.

Decision Matrix: Selecting the Right Thermal Strategy

Engineers must weigh the trade-offs between complexity, cost, and capability. The following table compares the three most common cooling technologies for outdoor cabinets: Open-Loop Fans, Thermoelectric Coolers (TEC/Peltier), and Micro DC Air Conditioners (Compressor-based).

| Criteria | Open-Loop Fans | Thermoelectric (TEC) | Micro DC Aircon (Compressor) |

|---|---|---|---|

| Cooling Mechanism | Ambient Air Exchange | Peltier Effect (Solid State) | Vapor Compression Cycle |

| Sub-Ambient Capability | Impossible (Always > Ambient) | Yes (Limited Delta T) | Yes (High Delta T) |

| Sealed Enclosure (NEMA/IP) | No (Requires Vents) | Yes (Closed Loop) | Yes (Closed Loop) |

| Cooling Capacity Range | Depends on Airflow | Typically 50W – 300W | Typically 100W – 900W+ |

| Efficiency (COP) | High (Low power draw) | Low (COP 0.5 – 0.8) | High (COP 2.0 – 3.5) |

| Dust/Humidity Tolerance | Low (Filters clog, moisture enters) | High (No ingress) | High (No ingress) |

| Best-Fit Scenario | Indoor / Clean / Low Heat | Small Enclosures / Low Heat | High Heat / Solar / Harsh |

Implication: Fans are disqualified for sealed or sub-ambient needs. TECs are viable for very small loads but become power-inefficient as heat loads rise. Compressor-based Micro DC Aircons offer the best balance of capacity and efficiency for robust outdoor systems.

Quick Selection Rules for Design Reviews

When evaluating your thermal strategy, apply these binary logic rules to filter out non-viable options immediately:

- Rule 1: If the target internal temperature is equal to or lower than the maximum ambient temperature, you must use active cooling (Compressor or TEC). Fans cannot defy physics.

- Rule 2: If the environment contains conductive dust, salt spray, or condensing humidity, you must use a closed-loop system (Sealed Enclosure).

- Rule 3: If the heat load exceeds 300W and power is limited (battery/solar), a compressor-based system is typically preferred over TEC due to superior Coefficient of Performance (COP).

- Rule 4: If the system runs on DC battery power (12V/24V/48V), avoid AC-voltage cooling units to eliminate inverter losses and reliability risks.

- Rule 5: If solar loading is present, add approximately 15%–20% to your calculated internal heat load to account for radiant gain, unless heavy shielding is applied.

Engineering a Micro AC for Outdoor Electrical Cabinet Strategy

Implementing a micro ac for outdoor electrical cabinet designs requires a shift in thinking from simple airflow management to thermodynamic system design. Unlike fans, which simply move air, a micro AC is a heat pump. It actively transports thermal energy from the evaporator (inside the cabinet) to the condenser (outside), regardless of the temperature gradient.

The Unseen Enemies of Uptime

Why do standard cooling approaches fail in the field? The causes are often invisible during the design phase but become catastrophic in deployment.

- Filter Clogging (The Silent Killer): In open-loop systems, filters are the first line of defense. In dusty environments (mines, deserts, agriculture), these filters clog rapidly. As static pressure increases, airflow drops precipitously. The result is a thermal runaway where the cooling system is technically “running” but providing zero heat rejection.

- Humidity and Condensation: Even if a cabinet is technically “weatherproof,” diurnal temperature cycling can cause pressure differentials that suck moist air in through gaskets. Once inside, this moisture condenses on cold surfaces—often the cooling unit itself or sensitive PCBs. Closed-loop AC units manage this by dehumidifying the internal air, collecting condensate, and draining it externally.

- Solar Gain Saturation: A white cabinet reflects some sunlight, but a grey or dark cabinet absorbs massive amounts of energy. In passive systems, this solar gain consumes the entire thermal budget, leaving no headroom for the electronics’ own heat generation.

Engineering Fundamentals: The Physics of Rejection

To justify the selection of a micro DC air conditioner, we must look at the fundamental mechanism of heat rejection. The core advantage of a vapor-compression system is the phase change of the refrigerant. By compressing a gas (like R134a or R290) into a liquid and then allowing it to expand and evaporate, the system absorbs a tremendous amount of latent heat from the internal air.

This process allows the system to maintain a “Delta T” (temperature difference) that is positive relative to the ambient air. In other words, it can reject heat into 50°C outside air while keeping the inside at 25°C. This is the “sub-ambient” capability that fans lack. Furthermore, because the system is closed-loop, the internal air is recirculated. It passes over the cold evaporator coil, drops its heat (and moisture), and is blown back over the components. The external loop uses a separate fan to blow ambient air over the hot condenser coil, rejecting the heat to the atmosphere.

Delta T Limits: It is important to understand that even active cooling has limits. The capacity of the unit is often rated at specific conditions (e.g., L35/L35 – 35°C internal, 35°C ambient). As the ambient temperature rises, the condensing pressure increases, and the compressor must work harder. However, unlike TECs which see a drastic drop in efficiency at high Delta T, a well-designed DC compressor maintains robust capacity even in high-ambient conditions.

Performance Data & Verified Specs

When specifying a solution, vague marketing terms like “high capacity” are dangerous. You need verified data. Below are the specifications for the Micro DC Aircon (Pro Series), which utilize miniature BLDC inverter compressors to achieve high cooling density in a compact footprint.

| Model (Series) | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a | BLDC Inverter Rotary |

| DV1920E-AC (Pro) | 24V | 450W | R134a | BLDC Inverter Rotary |

| DV1930E-AC (Pro) | 48V | 450W | R134a | BLDC Inverter Rotary |

| DV3220E-AC (Pro) | 24V | 550W | R134a | BLDC Inverter Rotary |

These units feature variable-speed blower control and an integrated driver board, allowing for precise thermal regulation. The use of DC voltage (12V/24V/48V) allows for direct integration with battery banks or solar controllers, bypassing the need for inefficient AC inverters.

Field Implementation Checklist

Selecting the right unit is only half the battle. Integration determines long-term reliability. Based on field data from hundreds of deployments, here is a checklist for system integrators:

Mechanical Integration

- Sealing Integrity: Ensure the cutout for the AC unit is precise. Use high-quality closed-cell foam gaskets. Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality.

- Airflow Management: Do not block the intake or exhaust of the AC unit. Inside the cabinet, ensure the cold air discharge is directed towards the hottest components (e.g., the CPU or power supply) but avoid “short-cycling” where cold air is immediately sucked back into the return.

- Condensate Routing: Active cooling removes moisture. Ensure the condensate drain tube is routed outside the cabinet and has a trap or valve to prevent insect ingress.

Electrical Integration

- Cable Sizing: DC compressors can draw significant current, especially at 12V. Undersized cables lead to voltage drop, which can trigger the unit’s low-voltage protection cutoff. Calculate voltage drop based on cable length and peak current.

- Circuit Protection: Always install a dedicated fuse or breaker for the cooling unit. While the integrated driver board has protection, external redundancy is best practice.

Expert Field FAQ

Q: How do I size a micro ac for outdoor electrical cabinet applications correctly?

A: You must calculate the total heat load: Internal Heat Dissipation (Watts) + Solar Load (Watts) + Heat Transfer through walls (Watts). A common mistake is ignoring the solar load, which can account for 20-30% of the total requirement in unshaded cabinets.

Q: Can these units run directly off solar panels?

A: Typically, no. They should run off the battery bank that the solar panels charge. The compressor requires a stable voltage source. Connecting directly to panels can cause rapid cycling due to voltage fluctuations from cloud cover.

Q: What is the maintenance interval?

A: For the internal loop, maintenance is virtually zero as it is sealed. For the external loop, the condenser coil may need cleaning (compressed air or brush) depending on dust levels. However, there are no filters to replace, which significantly reduces truck rolls compared to fan-based systems.

Q: How does the “Soft Start” feature help?

A: The BLDC inverter compressor ramps up speed gradually. This eliminates the massive inrush current spike typical of traditional AC compressors, which is critical for protecting battery life and preventing voltage sag on the DC bus.

Q: What happens if the battery voltage gets too low?

A: The integrated driver board features low-voltage protection. It will cut off the compressor to prevent deep discharge of the battery, ensuring that critical monitoring equipment remains powered as long as possible.

Q: Is R134a the only refrigerant option?

A: While R134a is standard for many models like the DV series, options for R290 and R1234yf exist for projects requiring low-GWP (Global Warming Potential) compliance. Check specific model availability.

Conclusion & System Logic

The shift from passive to active cooling is a significant design decision, but for outdoor electronics, it is often the only path to guaranteed reliability. By selecting a Micro DC Aircon, engineers can decouple their equipment from the harsh external environment. The logic is straightforward: if the cost of downtime exceeds the cost of the cooling solution, active cooling is the correct investment.

When selecting a micro ac for outdoor electrical cabinet deployment, focus on the “Three S’s”: Sizing (including solar), Sealing (maintaining the loop), and Supply (clean DC power). A system designed with these pillars will survive the desert sun, the ocean spray, and the dust storms that defeat lesser designs.

Request Sizing Assistance

Don’t guess on thermal calculations. To get a precise sizing recommendation for your application, please prepare the following inputs and consult our engineering team:

- Target Internal Temperature: (e.g., 35°C)

- Maximum Ambient Temperature: (e.g., 50°C)

- Internal Heat Load: (Total Watts of all components)

- Cabinet Dimensions & Material: (H x W x D, Steel/Aluminum/Plastic)

- Power Source: (12V, 24V, or 48V DC)

- Environmental Constraints: (Solar load, salt spray, dust level)

0 条评论