The Hidden Interface: Why Cooling Capacity Means Nothing Without Sealing Integrity

In the design of outdoor infrastructure—whether for telecom base stations, remote monitoring skids, or off-grid battery cabinets—engineering attention naturally gravitates toward the active components. We calculate heat loads, size battery banks, and select cooling units based on thermal dissipation requirements. However, a 450W cooling system is only as effective as the boundary it protects. If the interface between the cooling unit and the cabinet fails, the controlled environment is lost, leading to humidity ingress, condensation, and eventual component corrosion.

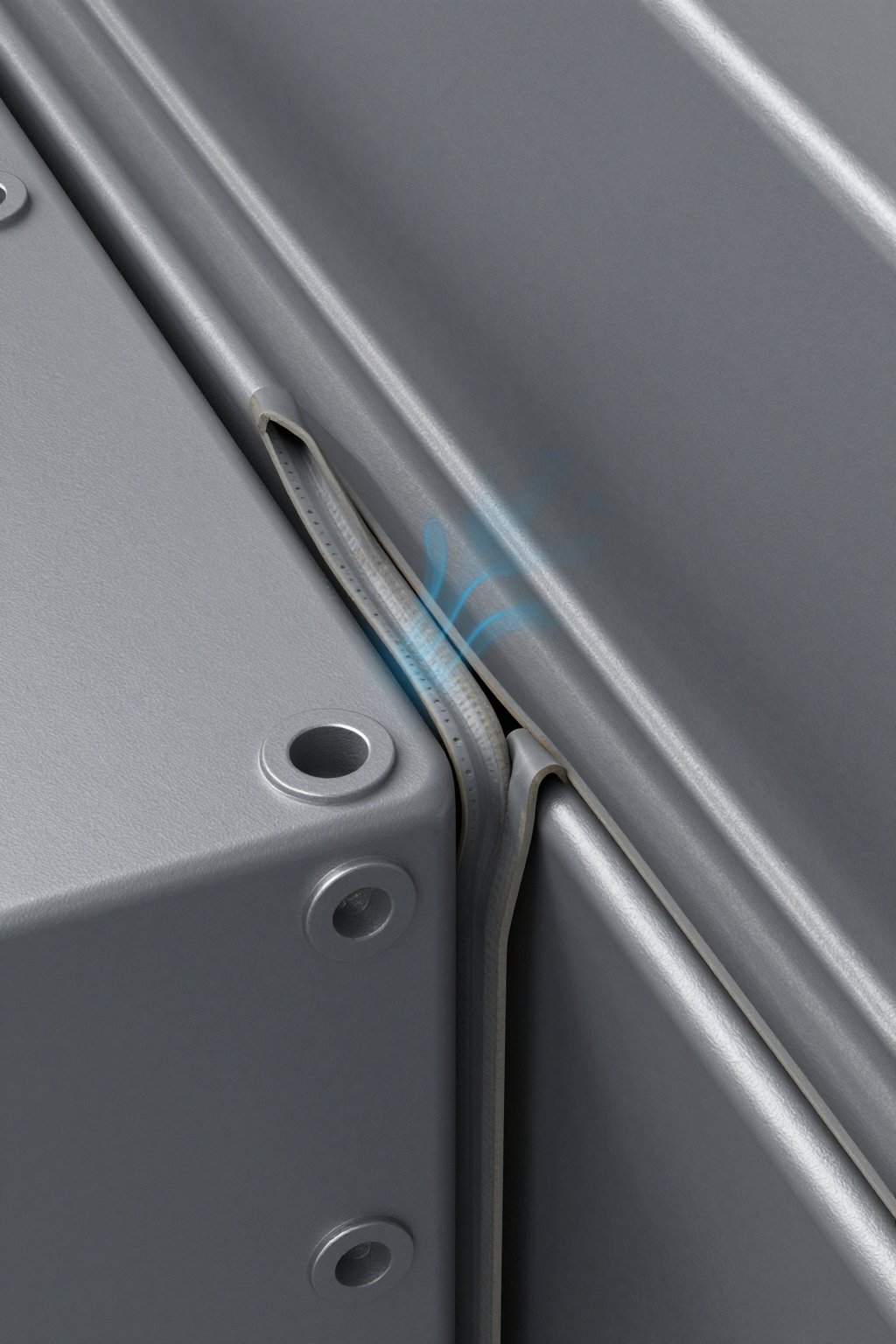

For mechanical engineers and system integrators, enclosure cutout sealing reliability is often the single point of failure in harsh deployments. A panel-mounted DC air conditioner does not merely sit on a cabinet; it interacts dynamically with the structure. Thermal cycling causes expansion and contraction, wind loads induce vibration, and UV exposure degrades gasket materials. Over time, these forces conspire to create leak paths that bypass even the most robust IP-rated cooling units.

This article examines the mechanics of seal fatigue and provides a forensic approach to preventing leak paths in panel-mounted DC cooling applications. We will move beyond simple NEMA/IP ratings to discuss the physical realities of maintaining a hermetic seal in environments defined by extreme temperature swings and mechanical stress.

Deployment Context: Where Sealing Fails First

To understand the stress placed on enclosure seals, we must look at the specific environmental profiles where these systems operate. The following scenarios illustrate common failure modes in the field.

Scenario A: The High-Desert Telecom Repeater

Consider a solar-powered telecom cabinet deployed in a region like Arizona or the Australian Outback. The ambient temperature can swing from 10°C at night to 50°C during the day.

The Constraint: This 40-degree swing drives significant thermal expansion and contraction in the metal cabinet walls. If the cooling unit’s chassis (often aluminum or coated steel) expands at a different rate than the cabinet door (often steel), the resulting shear stress creates a “scrubbing” action on the gasket. Over thousands of cycles, this compromises enclosure cutout sealing reliability, leading to dust ingress during dust storms.

Scenario B: Coastal Sensor Platforms

A monitoring station on an offshore platform or coastal cliff faces constant salt spray and high humidity.

The Constraint: Here, the primary enemy is not just thermal movement but chemical attack and pressure differentials. As the internal air cools rapidly when the DC air conditioner cycles on, the internal pressure drops. If the seal has lost its restoring force (compression set), moist, salty air is drawn in through the micro-gaps. This “breathing” effect accelerates corrosion on the cooling unit’s flange and the cabinet cutout, eventually undermining the structural integrity of the mount.

Decision Matrix: Cooling Architecture & Sealing Risks

Selecting a cooling technology is not just about thermal management; it is a decision about enclosure integrity. The table below compares common cooling approaches and their impact on sealing and maintenance.

| Technology | Sealing Architecture | Ingress Risk Profile | Thermal Headroom | Typical Maintenance |

|---|---|---|---|---|

| Passive Vents / Louvers | Open Loop | High. Relies entirely on filters; does not seal against humidity or gas. | None (Ambient = Internal) | Frequent filter changes required. |

| DC Fan / Filter Fans | Open Loop | Moderate to High. Positive pressure helps, but filter clogging reverses flow or burns out fans. | None (Ambient < Internal required) | High. Filter cleaning is critical to prevent overheating. |

| Micro DC Aircon (Panel Mount) | Closed Loop | Low. Isolates internal air. Risk is concentrated entirely at the mounting flange/gasket. | High (Sub-ambient capability) | Low. No filters to change; focus is on condenser cleaning. |

| Air-to-Air Heat Exchanger | Closed Loop | Low. Similar flange sealing requirements to AC units. | Limited (Depends on ambient delta) | Moderate. Core cleaning required. |

Implication: For harsh environments, closed-loop systems (Micro DC Aircon or Heat Exchangers) are the only viable option to stop contaminants. However, this shifts the entire burden of ingress protection to the mounting interface. Enclosure cutout sealing reliability becomes the critical success factor.

Quick Selection Rules for the Design Review

- If the deployment site has conductive dust (coal, iron) or salt fog, then open-loop fans are disqualified; a closed-loop Micro DC Aircon is required to prevent board shorts.

- If the cabinet wall thickness is less than 2mm, then a reinforcement plate (stiffener) is usually required to prevent panel flex from compromising the gasket seal.

- If the ambient temperature exceeds the target internal temperature, then passive cooling and fans will physically fail to cool; active refrigeration is mandatory.

- If the unit is mounted on a door, then cable management must account for hinge movement to prevent strain on the glands, which is a secondary leak path.

- If the daily temperature swing exceeds 20°C, then gasket material selection (e.g., EPDM vs. Neoprene) matters significantly for long-term elasticity.

Failure Modes: The Unseen Enemies of Uptime

When a panel-mounted cooling unit leaks, it is rarely due to a hole in the unit itself. It is almost always an interface failure. Here are the specific mechanisms that degrade enclosure cutout sealing reliability.

1. Compression Set and “Relaxation”

All elastomeric gaskets lose their ability to push back against the mating surfaces over time. This is known as compression set. In high-heat environments, this process accelerates. If a gasket takes a 100% set, it no longer exerts pressure on the cabinet wall. The moment the cabinet flexes or vibrates, a gap opens, and the seal is lost.

2. The “Pumping” Effect

As mentioned in the deployment scenarios, cabinets “breathe” due to pressure changes caused by internal heating and cooling cycles. A Micro DC Aircon cycles on, dropping the internal temperature. According to the ideal gas law, pressure drops. If the gasket is weak, the cabinet sucks in outside air (and moisture). When the unit turns off and the cabinet heats up, pressure rises, pushing air out. This daily pumping action brings in fresh moisture every cycle, eventually saturating desiccant packs and condensing on cold surfaces.

3. CTE Mismatch and Shear

Coefficient of Thermal Expansion (CTE) mismatch is a subtle killer. If you mount an aluminum-chassis cooler onto a steel cabinet, they expand at different rates. This creates shear stress across the gasket face. Over time, this can tear the gasket skin or cause it to “walk” out of position if not properly adhered or channel-mounted.

Engineering Fundamentals: Why Closed-Loop Matters

To combat these failure modes, engineers often turn to closed-loop cooling solutions like the Micro DC Aircon series. The fundamental advantage here is the physical isolation of the evaporator (internal) air path from the condenser (external) air path.

In a Micro DC Aircon system, the refrigerant loop moves heat without moving air between the inside and outside. This allows the cabinet to remain hermetically sealed. However, this design relies on the assumption that the mounting interface is perfect. Closed-loop designs avoid air exchange, but overall ingress protection still depends on gasket integrity, cable glands, and installation quality.

Furthermore, the use of DC inverter technology in these units helps mitigate mechanical stress. Unlike traditional AC compressors that start with a violent “bang” (high inrush torque), DC inverter compressors soft-start. This ramping action significantly reduces the mechanical shock and vibration transferred to the mounting panel, thereby reducing the fatigue load on the gasket and fasteners over the system’s life.

Performance Data: Verified Specifications

When selecting a unit for panel mounting, physical characteristics and cooling capacity are paramount. The following table outlines the verified specifications for the DV series Micro DC Aircon. Note the voltage options, which allow direct integration with battery or solar DC buses, eliminating the need for inverters that add heat and failure points.

| Model | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC | 12V | 450W | R134a | BLDC Inverter Rotary |

| DV1920E-AC | 24V | 450W | R134a | BLDC Inverter Rotary |

| DV1930E-AC | 48V | 450W | R134a | BLDC Inverter Rotary |

| DV3220E-AC | 24V | 550W | R134a | BLDC Inverter Rotary |

Note: Cooling capacity and power draw vary based on ambient temperature and control settings. The rotary compressor design contributes to a compact footprint, reducing the lever-arm effect on the mounting panel compared to bulkier AC units.

Field Implementation Checklist

Ensuring enclosure cutout sealing reliability requires strict adherence to installation best practices. Use this checklist during the design and prototype phase.

Mechanical & Sealing

- Cutout Precision: Ensure the cutout dimensions match the manufacturer’s template exactly. Oversized cutouts reduce the gasket contact area.

- Surface Preparation: Deburr all cut edges. Sharp burrs can slice through gaskets during installation or thermal expansion. Ensure the mating surface is flat and free of paint runs or weld splatter.

- Stiffening: If the cabinet wall is thin (e.g., 16 gauge or thinner) and the unit is heavy, weld or bond stiffener channels around the cutout to prevent bowing. Bowing creates gaps between fasteners.

- Torque Pattern: Tighten mounting nuts in a star or cross pattern to compress the gasket evenly. Do not fully tighten one bolt before starting others.

Thermal & Electrical

- Condensate Management: Ensure the condensate drain line is routed correctly and has a trap or one-way valve if required, to prevent it from becoming an air ingress path.

- Cable Glands: Use rated cable glands for power and control wires entering the cabinet. A sealed cooler is useless if the cable pass-through is open.

- Solar Shielding: Whenever possible, mount the cooling unit on the shaded side of the cabinet or install a solar shield. Direct sun degrades gaskets and reduces cooling efficiency.

Expert Field FAQ

Q: Does an IP65 rating on the cooling unit guarantee the whole cabinet is IP65?

A: No. The unit itself may be IP65, but the system rating depends entirely on the quality of the installation interface. If the gasket is compressed unevenly or the cutout is warped, the system will leak regardless of the unit’s rating.

Q: Can I use silicone sealant instead of the provided gasket?

A: In many deployments, this is discouraged. Silicone makes maintenance and unit replacement extremely difficult. It can also outgas, potentially affecting sensitive optics or sensors inside. A high-quality closed-cell foam or EPDM gasket is preferred for serviceability and consistent enclosure cutout sealing reliability.

Q: How does the Micro DC Aircon help with sealing compared to AC units?

A: Micro DC Aircon units are typically lighter and more compact than traditional AC units. This reduced mass puts less static load on the panel and gasket, reducing the likelihood of panel deformation over time.

Q: What is the impact of “short cycling” on the seal?

A: Rapid on/off cycling causes frequent pressure fluctuations (the “pumping” effect described earlier). Inverter-driven DC compressors can ramp down to match the load rather than cycling off completely, maintaining a more stable internal pressure and temperature, which is better for seal longevity.

Q: How often should gaskets be inspected?

A: In mild climates, an annual inspection is usually sufficient. In high-UV or extreme temperature environments, inspect seals every 6 months for signs of cracking, brittleness, or permanent compression set.

Q: Why is the “star pattern” tightening so important?

A: Tightening bolts in a circular sequence pushes the gasket material ahead of the torque, creating a “wave” or bunching effect that leads to leaks. A star pattern distributes compression evenly, ensuring flat contact.

Conclusion: The Interface is the System

In the world of outdoor infrastructure, the cooling unit is often viewed as a bolt-on accessory. This mindset leads to failure. The cooling unit, the gasket, and the cabinet wall form a unified thermal and structural system. Neglecting the interface—the cutout, the flange stiffness, the torque specs—compromises the entire investment.

By choosing closed-loop solutions like the Micro DC Aircon series, engineers eliminate the risks associated with filter maintenance and open-loop airflow. However, the responsibility then shifts to ensuring enclosure cutout sealing reliability. Through careful attention to gasket selection, panel rigidity, and installation protocols, you can ensure that your harsh-environment deployments remain dry, cool, and operational for years to come.

Request a Sizing & Integration Consultation

Don’t leave your thermal design to guesswork. To get a precise sizing recommendation and integration advice for your specific application, please prepare the following inputs and contact our engineering team:

- Ambient Conditions: Max/Min Temperature and Solar Load exposure.

- Target Internal Temperature: Maximum allowable temp for your critical components.

- Heat Load: Estimated dissipation (Watts) of internal electronics.

- Power Source: Available DC Voltage (12V/24V/48V) and current limits.

- Sealing Target: Required IP or NEMA rating.

- Cabinet Details: Wall thickness, material, and cutout dimensions.

0 条评论