Angle: The decision to move from passive heat exchange to active, closed-loop air conditioning for a sealed power electronics cabinet. Key failure modes are thermal runaway of VFDs and moisture ingress from compromised seals. The dominant constraint is maintaining the enclosure’s NEMA/IP rating against a harsh external environment while managing high internal heat flux.

A Systems Approach to Power Electronics Cabinet Cooling

A leading cause of production line failure is not a catastrophic mechanical breakdown but a silent, thermal one. Inside a sealed industrial cabinet, a variable frequency drive (VFD) or servo amplifier quietly exceeds its maximum operating temperature and trips, shutting down a critical process. The cost of this downtime—whether on a factory floor or at a remote telecom site—far outweighs the cost of the electronics themselves. The challenge is that the very cabinet designed to protect these sensitive components from dust, moisture, and corrosive elements also traps their waste heat, creating a high-stakes engineering problem. Effective power electronics cabinet cooling is not an accessory; it is a core element of system reliability.

By the end of this article, you will be able to identify the specific environmental and thermal thresholds that make active, closed-loop cooling a non-negotiable requirement. You will have a clear, data-driven framework for selecting and integrating a solution that preserves your enclosure’s integrity while guaranteeing the performance of the electronics within. In this analysis, we prioritize maintaining the cabinet’s environmental seal and managing internal hot spots over simpler heat exchange methods, because the long-term ingress of contaminants is a primary, and often overlooked, vector for premature system failure.

Deployment Context: Where Passive Cooling Fails

The need for robust power electronics cabinet cooling becomes evident in specific, challenging environments. Two common scenarios illustrate the crossover point where simple fans and filters are no longer viable.

Scenario A: The Factory Floor Hot Zone

Consider a sealed NEMA 12 cabinet housing three VFDs that control a synchronized conveyor system in a metal fabrication plant. The cabinet is located twenty feet from a heat-treating furnace, where ambient air temperatures regularly spike to 45°C (113°F). The original design used a filtered fan, but the fine, oily mist in the factory air quickly clogged the filter media. This severely restricted airflow, causing the drives to trip on over-temperature faults during peak production. The constraint here is a contaminated, high-ambient environment that makes using outside air for cooling a direct threat to reliability.

Scenario B: The Outdoor Telecom Node

An IP65-rated cabinet is pole-mounted to service a 5G cellular node. Inside, power supplies, rectifiers, and a battery backup system generate a constant 400 watts of heat. The cabinet is exposed to direct solar radiation, adding a significant external heat load. On a sunny 35°C (95°F) day, the internal temperature can soar past 60°C (140°F), which dramatically shortens the service life of the batteries and derates the performance of the power conversion electronics. The primary constraint is the combination of solar gain and the absolute requirement for a watertight seal, making any form of air exchange with the outside impossible.

Common Failure Modes and System Constraints

When designing a power electronics cabinet cooling strategy, it’s crucial to anticipate how systems fail in the real world. These issues are often interconnected, starting with a thermal problem and cascading into mechanical or electrical faults.

- Symptom: Gradual performance derating → Cause: Internal temperature exceeds the electronics’ nominal operating range → Why it matters: Leads to reduced throughput and unpredictable shutdowns under full load.

- Symptom: Premature failure of capacitors and power modules → Cause: Sustained operation at elevated temperatures accelerates component aging (Arrhenius effect) → Why it matters: Drastically reduces system lifespan and increases total cost of ownership.

- Symptom: Visible corrosion on PCBs and bus bars → Cause: Condensation forms when a compromised seal allows humid air to contact surfaces cooled below the dew point → Why it matters: Causes irreversible electrical shorts and hardware damage.

- Symptom: Clogged heat sink fins and dirty components → Cause: Using filtered fans that inevitably pull in fine dust, oil, or moisture → Why it matters: Creates a costly and often-neglected maintenance burden that eventually leads to thermal failure.

- Symptom: Nuisance tripping of control panel breakers → Cause: High inrush currents from large, inefficient AC-powered cooling units stressing the power bus → Why it matters: Creates system instability and diagnostic headaches.

- Symptom: Warped cabinet doors and failed gaskets → Cause: Significant pressure differentials caused by aggressive cooling cycles or inadequate pressure compensation → Why it matters: Permanently compromises the enclosure’s NEMA/IP rating.

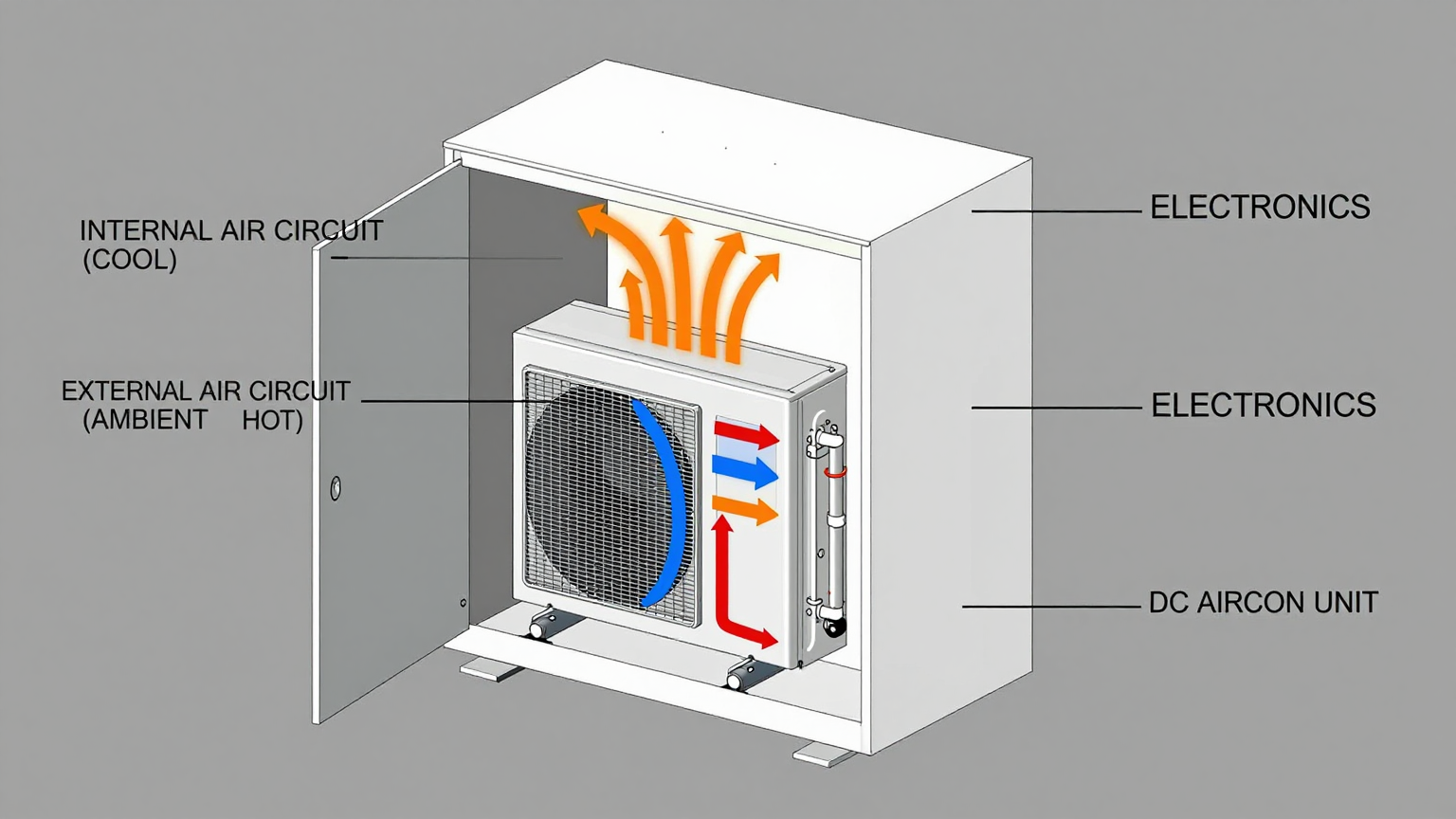

Engineering Fundamentals of Closed-Loop Cooling

The core principle that resolves the challenges of sealed enclosures is closed-loop cooling. Unlike a fan, which creates an open loop by drawing ambient air into the cabinet, a closed-loop system like a Micro DC Aircon maintains two completely separate air circuits. The internal circuit draws hot air from inside the cabinet, passes it over a cold evaporator coil to remove the heat, and returns chilled, dehumidified air back into the cabinet. The captured heat is then transferred via a refrigerant cycle to a condenser coil, where it is exhausted into the ambient environment by the external air circuit. This is the foundation of effective power electronics cabinet cooling for sealed designs.

This separation is critical. It allows you to maintain the cabinet’s NEMA or IP rating because no outside air ever enters the protected space. All dust, moisture, and corrosive agents from the ambient environment remain outside.

Misconception vs. Reality

- Misconception: “To solve my power electronics cabinet cooling problem, I just need to move more air with a bigger fan.”

- Correction: In a sealed or high-ambient environment, a fan is insufficient. If the ambient air is hotter than your target internal temperature, a fan actively heats the cabinet. If the air is dirty, a fan introduces contaminants. In a truly sealed box, a fan only circulates hot air, doing nothing to remove the thermal energy. The solution is not just moving air, but actively removing heat energy from the internal ecosystem.

Key Specifications for Active Cooling Units

When evaluating active cooling solutions, specific performance metrics serve as go/no-go gates in the design process. The nominal cooling capacity is the headline number, but voltage compatibility and refrigerant type are critical for integration and compliance. The table below shows baseline parameters for our Micro DC Aircon series, which are specifically designed for dense load enclosure cooling.

How to read these specs for your decision: The Nominal Cooling Capacity indicates the heat removal capability under standard test conditions. This value must be derated or adjusted based on your specific maximum ambient temperature and target internal temperature. The Voltage must match the available DC power bus in your cabinet (e.g., 24VDC for industrial controls, 48VDC for telecom), eliminating the need for a separate AC circuit or inefficient power conversion.

| Model (Example) | Voltage (DC) | Nominal Cooling Capacity (W) | Refrigerant |

|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a |

| DV1920E-AC (Pro) | 24V | 450W | R134a |

| DV1930E-AC (Pro) | 48V | 450W | R134a |

| DV3220E-AC (Pro) | 24V | 550W | R134a |

Engineering Selection Matrix: Logic Gates for Integration

Choosing the right thermal management strategy is a process of elimination based on hard constraints. An engineer must walk through these logic gates to arrive at a reliable solution for power electronics cabinet cooling.

Gate 1: The Seal Integrity Gate

- Constraint Gate: The cabinet requires a NEMA 4/12 or IP55/65 rating to protect against wash-downs, dust, or moisture.

- Decision Trigger: If the operating environment is anything other than a clean, climate-controlled room, any solution that compromises the seal (like a filtered fan) is immediately disqualified.

- Engineering Resolution: This mandates a closed-loop cooling architecture. The choice is now between a passive air-to-air heat exchanger or an active air conditioner.

- Integration Trade-off: This path requires a higher initial investment than a simple fan but is the only way to uphold the primary protective function of the enclosure and ensure long-term reliability.

Gate 2: The Thermal Delta Gate

- Constraint Gate: The relationship between the maximum external ambient temperature and the required maximum internal cabinet temperature.

- Decision Trigger: If the internal temperature must be maintained at or, critically, below the external ambient temperature, a passive heat exchanger is no longer viable. A heat exchanger can only approach the ambient temperature; it can never go below it.

- Engineering Resolution: The system requires active, refrigerant-based cooling. A Micro DC Aircon becomes the necessary choice, as it can create a significant negative temperature differential.

- Integration Trade-off: This introduces a vapor-compression system and a higher DC power draw. However, it is the key that unlocks zero-derating operation for your electronics, even on the hottest days.

Gate 3: The Heat Flux Density Gate

- Constraint Gate: The total internal heat load (in watts) versus the available surface area and internal volume of the cabinet. This is the core challenge of dense load enclosure cooling.

- Decision Trigger: When multiple high-power components like VFDs, power supplies, and inverters are packed into a compact enclosure, the heat flux (watts per unit volume) becomes too high for natural convection or simple passive solutions to manage. Hot spots will inevitably form.

- Engineering Resolution: An active system with forced-air convection is required. The cooling unit must create a deliberate, high-velocity airflow path—drawing hot air from the top of the cabinet and injecting chilled air at the bottom to cool the heat-generating components directly.

- Integration Trade-off: This may require adding simple baffles or ducting inside the cabinet to optimize the airflow path. It’s an extra integration step, but it enables dramatic miniaturization of the overall system footprint.

Implementation and Validation Checklist

Proper installation is as critical as proper selection for successful power electronics cabinet cooling. A methodical approach to integration and verification prevents common failures.

-

Mechanical Integration

- Mounting: Use the provided template to cut the mounting hole. Ensure the cabinet surface is flat and clean. Securely fasten the unit using all mounting points to handle vibration.

- Sealing: The gasket is the most critical component. Ensure it is properly seated and not twisted. Tighten mounting hardware in a star pattern to apply even compression and create a perfect seal.

- Airflow Integrity: Check that no cables, brackets, or components inside the cabinet obstruct the cool air outlet or the hot air return inlet of the cooling unit.

-

Electrical Integration

- Power Source: Connect the unit to a stable DC voltage source (e.g., 24VDC or 48VDC) that can supply the required continuous and peak current. Use the recommended wire gauge to prevent voltage drop.

- Overcurrent Protection: Install a fuse or circuit breaker in-line with the positive lead, rated according to the manufacturer’s specification.

- Control Signals: If using remote alarms or thermostat controls, ensure the wiring is correctly connected and shielded if necessary.

-

Thermal Validation

- Sensor Placement: To get a true picture of performance, place thermocouples or temperature sensors near the heat sinks of the most powerful components (VFDs, rectifiers) and one near the top of the cabinet to measure the hottest return air.

- Acceptance Test: With the cabinet fully loaded and running, monitor the internal temperatures. The system should be able to maintain the target temperature or lower, stabilizing without excessive cycling. This test should ideally be performed on a day with high ambient temperatures.

-

Maintenance Planning

- External Coils: The external (condenser) coils are the only part that requires routine maintenance. Schedule a quarterly or semi-annual inspection to clean away any accumulated dust or debris using compressed air.

- Seal Inspection: Annually, inspect the integrity of the mounting gasket and the main cabinet door seals to ensure the enclosure’s rating is not compromised.

Frequently Asked Questions about Power Electronics Cabinet Cooling

- Should I use a heat exchanger or a DC air conditioner for my power electronics cabinet cooling?

- A heat exchanger is viable only if you can tolerate an internal temperature that is always higher than the ambient air. If you need to cool the cabinet to a temperature at or below the surrounding ambient temperature, you must use an active DC air conditioner.

- What happens to my cabinet’s NEMA or IP rating when I install a cooling unit?

- Properly designed cooling units, like the Micro DC Aircon series, are built to integrate seamlessly with sealed enclosures. When installed correctly using the supplied gasket and mounting procedure, the unit maintains the cabinet’s original NEMA or IP rating.

- How do you manage condensation inside a sealed cabinet?

- Because a closed-loop system does not introduce new, humid air, internal condensation is minimized. The cooling process itself naturally dehumidifies the trapped internal air. Any condensate collected on the evaporator coil is managed through an integrated system that evaporates it into the external exhaust airflow.

- Can these units handle direct sun or corrosive environments like salt spray?

- Yes, but these factors must be included in the initial thermal calculation. Direct solar radiation adds a significant heat load that must be sized for. For highly corrosive or marine environments, custom configurations with specific coatings or stainless steel construction may be necessary. It’s critical to discuss these conditions during the specification phase.

- What is the most important measurement I need before selecting a cooler?

- The total internal heat load, measured in watts. This is the sum of the waste heat generated by all components inside the cabinet. The second and third most important factors are the maximum expected ambient temperature and your required internal operating temperature.

- How can I validate the cooling performance after installation?

- The best method is empirical testing. Use temperature sensors to log data from critical points inside the cabinet while the system is operating under its maximum electrical load on a warm day. The data will confirm if temperatures are stable and within the specified limits.

- Why is a variable-speed compressor important for power electronics cabinet cooling?

- A variable-speed (inverter) compressor and fans allow the cooling unit to precisely match its output to the real-time heat load. This is far more efficient than a traditional on/off system, resulting in significant energy savings, tighter temperature control, and reduced mechanical stress on the cooling components.

Conclusion: Matching the Solution to the Constraints

Ultimately, a robust strategy for power electronics cabinet cooling is an exercise in risk management. While simple fans are adequate for open-loop systems in clean, controlled environments, they become a liability when faced with sealed enclosure requirements and harsh operating conditions. The engineering logic gates—Seal Integrity, Thermal Delta, and Heat Flux Density—provide a clear path to a reliable solution.

An active, closed-loop Micro DC Aircon system is the best-fit solution when the application demands a sealed NEMA/IP rating, the internal temperature must be held at or below ambient, and the heat load is too dense for passive methods. This approach moves power electronics cabinet cooling from a potential point of failure to a cornerstone of system reliability. For applications like telecom components cooling, this is often the only viable path.

For a detailed thermal analysis of your project, including precise sizing calculations and integration support for unique enclosure geometries or power constraints, contact our engineering team to discuss your specific power electronics cabinet cooling requirements.

0 条评论