The Strategic Necessity of Correct Thermal Selection: Fans vs TEC vs Compressor Harsh Environment

In the realm of industrial systems engineering, the gap between a laboratory prototype and a field-deployed unit is often defined by thermal resilience. For OEM engineers and system integrators designing for remote, mobile, or outdoor applications, the choice of cooling topology is not merely a component selection—it is a fundamental determinant of system lifecycle and total cost of ownership (TCO). The debate surrounding fans vs tec vs compressor harsh environment suitability is critical because a mismatch here leads to catastrophic downtime, expensive truck rolls, and compromised component longevity.

This analysis adopts a strategic path, evaluating the Return on Investment (ROI) and lifecycle implications of thermal management decisions. We are not looking at ideal conditions; we are examining the “worst-case” scenarios where ambient temperatures soar, dust is pervasive, and power budgets are tight. By dissecting the fans vs tec vs compressor harsh environment equation, we aim to equip technical buyers with the data-driven logic required to specify the correct solution for high-stakes deployments.

Deployment Context: Where Standard Cooling Dies

To understand the fans vs tec vs compressor harsh environment dynamic, we must first establish the operational theater. We are focusing on applications where “standard” HVAC assumptions fail.

Scenario A: The Desert Telecom Repeater

Consider a remote telecom enclosure in the Mojave Desert. Ambient temperatures can peak at 50°C (122°F), while solar loading adds another 15°C to the internal cabinet temperature. The air is laden with fine silica dust. In this context, the fans vs tec vs compressor harsh environment decision is binary: if you choose a system that relies on ambient air exchange (fans), you introduce particulate matter that insulates PCBs and causes short circuits. If you choose a system with insufficient cooling density (TEC), the internal temperature spirals into thermal runaway.

Scenario B: The Offshore Sensor Node

A maritime sensor rig operates on a 24V battery bank charged by solar panels. The environment is defined by high humidity and corrosive salt spray. Here, the fans vs tec vs compressor harsh environment comparison shifts toward sealing and power efficiency. An open-loop fan system is non-viable due to corrosion. The choice narrows to closed-loop systems, but the power budget is strictly limited. A solution that draws excessive current will drain the batteries overnight, leading to system blackout.

Technical Friction Points: The Unseen Enemies of Uptime

When analyzing fans vs tec vs compressor harsh environment performance, specific failure modes emerge for each technology. These are the friction points that degrade reliability over time.

- Particulate Ingress (The Fan Failure Mode): In open-loop cooling, filters are the primary defense. However, in high-dust environments, filters clog rapidly, reducing airflow and increasing static pressure. This forces fans to work harder, reducing their lifespan and eventually leading to thermal shutdown when airflow drops below critical levels.

- Thermal Saturation (The TEC Failure Mode): Thermoelectric Coolers (TECs) rely on the Peltier effect. While solid-state, they suffer from a drastic drop in efficiency as the temperature differential (Delta T) increases. In a fans vs tec vs compressor harsh environment scenario where the ambient is 50°C, a TEC struggles to maintain an internal temperature of 25°C without consuming massive amounts of power, often generating more waste heat than they remove.

- Vibration and Power Surge (The Traditional Compressor Failure Mode): Standard AC compressors are often too bulky and susceptible to vibration damage in mobile applications. They also require high starting currents (inrush) that can trip sensitive DC power supplies. This is where specialized Micro DC Aircon solutions differentiate themselves in the fans vs tec vs compressor harsh environment matrix.

Engineering Fundamentals: Fans vs TEC vs Compressor Harsh Environment Analysis

To make a defensible engineering decision, we must strip away the marketing and look at the thermodynamics and physics governing the fans vs tec vs compressor harsh environment landscape.

1. Fans (Open-Loop Cooling)

Mechanism: Forced convection using ambient air.

The Physics: Heat transfer is driven by the temperature difference between the component and the ambient air.

The Limitation: You can never cool below ambient temperature. In fact, due to thermal resistance, the internal temperature will always be higher than ambient. In a fans vs tec vs compressor harsh environment evaluation, fans are disqualified immediately if the target internal temperature must be lower than the external maximum (e.g., keeping a battery at 25°C when it is 45°C outside). Furthermore, they break the NEMA/IP seal, exposing electronics to humidity and dust.

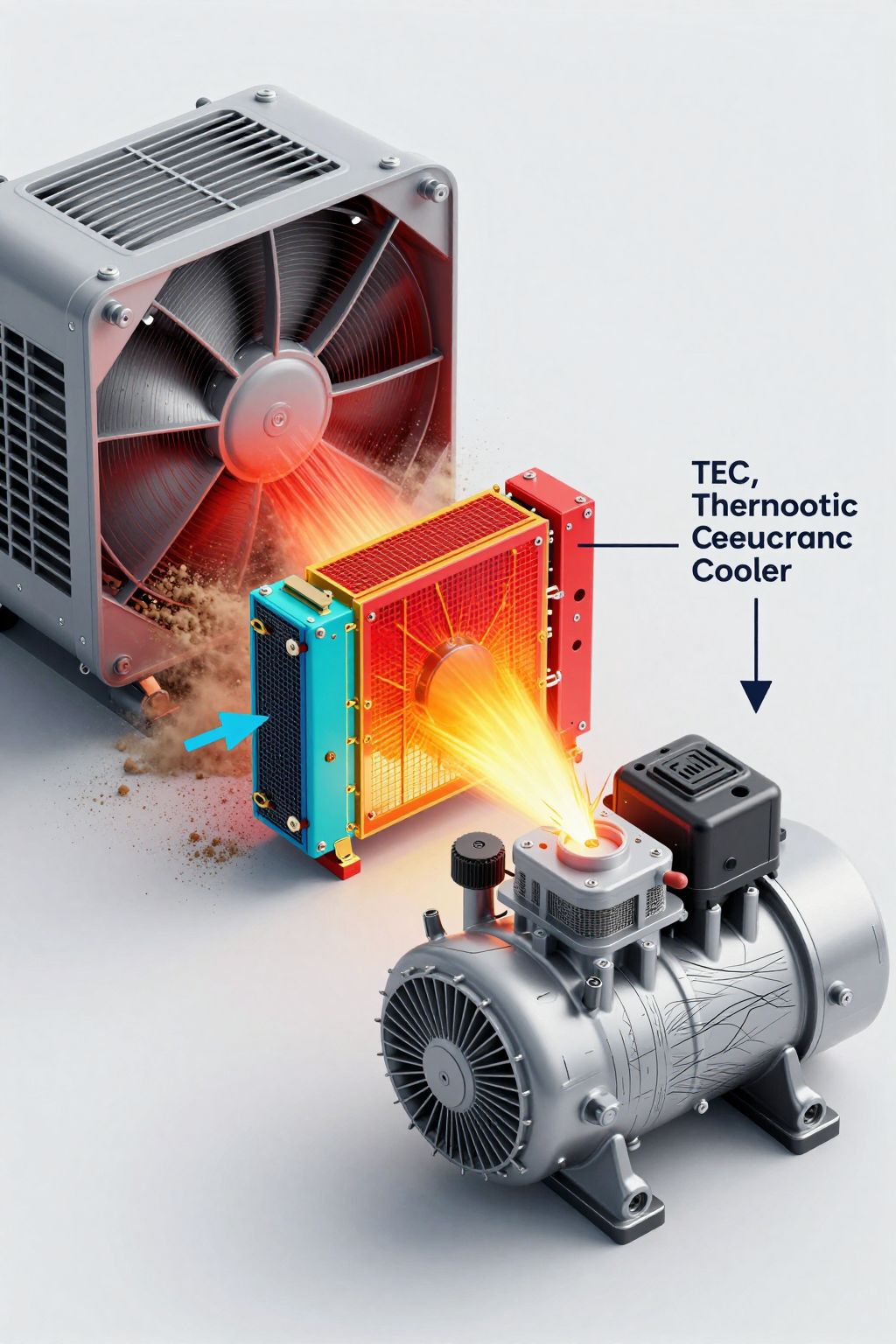

2. Thermoelectric Coolers (TECs / Peltier)

Mechanism: Solid-state heat pumping via the Peltier effect.

The Physics: Current flows through dissimilar semiconductors, transferring heat from the cold side to the hot side.

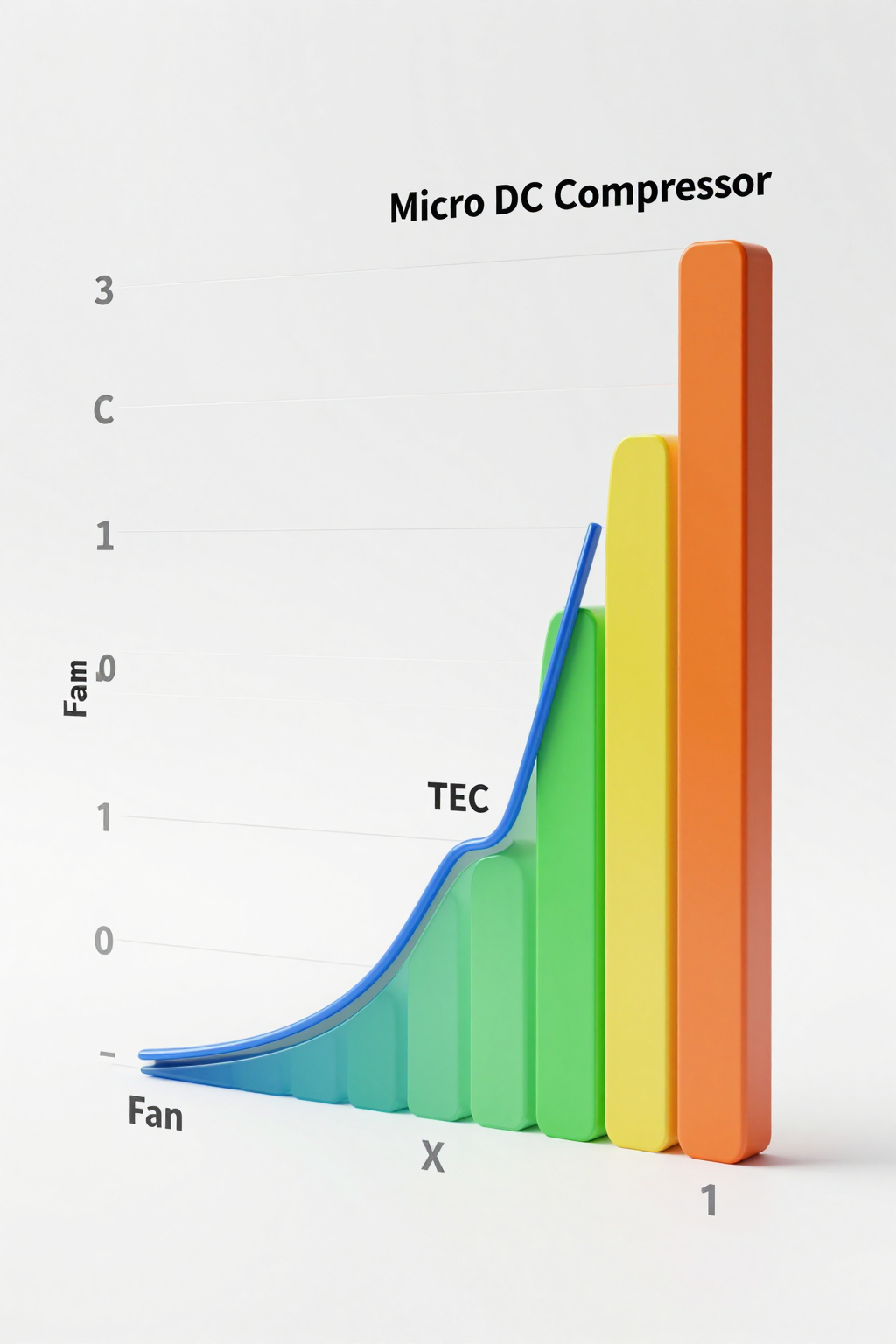

The Limitation: Efficiency (COP) is generally low, often below 0.6. This means for every 100W of cooling, you might burn 150W+ of electricity. In the fans vs tec vs compressor harsh environment debate, TECs are viable only for very small heat loads (typically under 50-100W) or where vibration is absolutely zero. Above these loads, the power penalty becomes unsustainable for battery-operated systems.

3. Micro DC Compressors (Vapor Compression)

Mechanism: Phase-change cooling using a refrigerant cycle (Compressor, Condenser, Expansion Valve, Evaporator).

The Physics: The latent heat of vaporization absorbs massive amounts of energy. Modern BLDC inverter compressors allow for variable speed control, matching cooling output to the load.

The Advantage: Vapor compression offers a Coefficient of Performance (COP) typically between 2.0 and 4.0. This means 100W of electrical input can move 300W of heat. In the context of fans vs tec vs compressor harsh environment applications, this is the only technology capable of active sub-ambient cooling with high energy efficiency. The Micro DC Aircon series utilizes miniature DC compressors to bring this power into a compact form factor, bridging the gap between massive industrial ACs and weak TECs.

Performance Data & Verified Specs

When the engineering requirements dictate active cooling (sub-ambient capability) and high efficiency, the data heavily favors vapor compression solutions like the Micro DC Aircon. Below are the verified specifications for the DV series, which utilize miniature DC compressors to solve the fans vs tec vs compressor harsh environment challenge.

| Model (Series Example) | Voltage (DC) | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V | 450W | R134a | Miniature BLDC Inverter |

| DV1920E-AC (Pro) | 24V | 450W | R134a | Miniature BLDC Inverter |

| DV1930E-AC (Pro) | 48V | 450W | R134a | Miniature BLDC Inverter |

| DV3220E-AC (Pro) | 24V | 550W | R134a | Miniature BLDC Inverter |

Data Analysis:

The DV series demonstrates that high cooling capacity (450W–550W) is achievable at standard DC voltages (12V/24V/48V). In a fans vs tec vs compressor harsh environment comparison, achieving 450W of cooling with a TEC would likely require over 800W of power input and a massive physical footprint. The Micro DC Aircon achieves this with a fraction of the power draw, preserving battery life in off-grid applications.

Field Implementation Checklist: Best Practices

Selecting the technology is step one. Integrating it successfully is step two. Whether you lean towards fans vs tec vs compressor harsh environment solutions, the implementation details often dictate reliability.

Mechanical Integration

- Sealing Integrity: If using a Micro DC Aircon or TEC, ensure the enclosure is fully sealed (NEMA 4/4X or IP65+). Any air leaks will introduce moisture, causing condensation on the evaporator coil that can overwhelm the condensate management system.

- Airflow Management: Avoid “short-cycling.” Ensure the cold air discharge is not immediately sucked back into the return intake. Use ducting or baffles to direct cold air toward the hottest components (e.g., IGBTs or processors).

Electrical & Power

- Voltage Drop: In 12V systems, cable resistance is a significant enemy. Use heavy-gauge wiring to prevent voltage drops during compressor startup, even though BLDC inverters have soft-start capabilities.

- Protection: Implement fusing and reverse polarity protection. While the Micro DC Aircon driver boards often include logic for protection, external redundancy is a best practice in remote sites.

Thermal Logic

- Hysteresis: Program your controller with adequate hysteresis (e.g., turn on at 35°C, turn off at 30°C) to prevent rapid cycling, which wears out components regardless of the fans vs tec vs compressor harsh environment choice.

- Solar Shielding: Always install cooling units on the shaded side of the cabinet or use a solar shield. Direct solar gain can de-rate the effective cooling capacity by 20-30%.

Expert Field FAQ

Q: In a fans vs tec vs compressor harsh environment analysis, when is a fan actually the right choice?

A: Fans are the correct choice only if two conditions are met: 1) The ambient air is clean (or can be reliably filtered without frequent maintenance), and 2) The internal components can tolerate temperatures significantly higher than the maximum ambient temperature. If your electronics need to be at 30°C and the air is 40°C, a fan is physically incapable of doing the job.

Q: Why not just use a large TEC for 400W loads?

A: It comes down to efficiency and heat rejection. To pump 400W of heat, a TEC might generate an additional 400W-600W of waste heat. You would need a massive heatsink and fan assembly just to manage the TEC’s hot side. A Micro DC Aircon solution handles this load with significantly less power and a smaller physical footprint.

Q: How do Micro DC Compressors handle vibration compared to standard AC compressors?

A: Standard AC compressors are heavy and suspended on internal springs that can bottom out under shock. Miniature DC compressors, like those in the DV series, are designed for mobile applications. They are lighter, have lower rotational mass, and are often mounted with specialized rubber grommets that dampen high-frequency vibrations common in vehicles or machinery.

Q: What about refrigerant leaks in rugged environments?

A: Modern Micro DC Aircon units are hermetically sealed and factory-charged. Unlike split systems that require field piping (and thus introduce leak points), these are typically monoblock units. Unless the copper tubing is physically punctured by external impact, the risk of leakage is extremely low.

Q: Does the refrigerant type matter in the fans vs tec vs compressor harsh environment decision?

A: Yes. R134a is standard and widely available. However, for high-ambient tropical versions, specific compressor tunings are used. The verified models listed (e.g., DV1920E-AC) use R134a, which has a critical temperature well suited for most industrial ranges up to 55°C ambient.

Q: Can I run a Micro DC Aircon directly off a solar panel?

A: Not directly. You need a battery buffer. While the compressor is DC, solar output fluctuates wildly. A battery bank stabilizes the voltage (12V/24V/48V) ensuring the inverter driver receives clean power.

Conclusion & System Logic

The decision matrix for fans vs tec vs compressor harsh environment applications is not about finding a “perfect” technology, but about matching the physics of cooling to the reality of the deployment.

If your system operates in a clean, climate-controlled room where internal temperatures can exceed ambient, fans are sufficient. If you have a tiny heat load (under 50W) and require precise temperature stability without moving parts, a TEC may be justifiable despite the inefficiency.

However, for the vast majority of outdoor, remote, and mobile industrial applications where heat loads range from 100W to 900W and power efficiency is paramount, the vapor compression cycle remains the superior engineering choice. The Micro DC Aircon series leverages the high COP of miniature DC compressors to provide active, sub-ambient cooling that fans cannot achieve and energy efficiency that TECs cannot match. By selecting a closed-loop compressor-based system, you isolate your critical electronics from dust, moisture, and heat, effectively insuring your project against the most common causes of field failure.

For engineers ready to transition from passive or inefficient cooling to robust active thermal management, Arctic-tek offers the expertise to size and specify the correct Micro DC solution for your unique environmental constraints.

0 条评论