The Strategic Imperative of Sealed Outdoor Enclosure Cooling

In the realm of industrial automation and outdoor kiosk design, the decision between passive ventilation and active cooling is rarely a matter of preference—it is a calculation of risk, longevity, and total cost of ownership (TCO). For OEM engineers and system integrators, the pressure to minimize upfront hardware costs often conflicts directly with the requirement for long-term reliability in hostile environments. This friction is most evident when designing for sealed outdoor enclosure cooling applications where the margin for thermal error is effectively zero.

The “set and forget” mentality that governs indoor IT infrastructure is disastrously inadequate for outdoor deployments. When a system is placed in a remote desert location, a coastal monitoring station, or a roadside utility cabinet, it faces an assault from environmental variables that static design models often fail to predict. The primary challenge is not merely removing heat; it is removing heat while maintaining a hermetically sealed barrier against dust, moisture, and corrosive elements. This article analyzes the engineering tradeoffs involved in this decision, providing a data-driven justification for when and why active cooling solutions, such as the Micro DC Aircon series, become the only viable path to system integrity.

By the end of this analysis, technical buyers and designers will have a clear framework for evaluating thermal loads and understanding why the initial investment in active sealed outdoor enclosure cooling pays dividends in uptime and component lifespan.

Deployment Context: High-Stakes Environments

To understand the necessity of active cooling, we must first contextualize the environments where these systems operate. We are not discussing climate-controlled server rooms. We are discussing the edge of the grid.

Scenario A: The Solar-Baked Telecom Node

Consider a remote telecom repeater station in the Nevada desert. Ambient temperatures regularly exceed 45°C (113°F). However, ambient temperature is only part of the equation. Solar loading—the radiant heat absorbed by the enclosure’s surface—can raise the internal cabinet temperature by an additional 15°C to 20°C above ambient. In this scenario, a passive cooling system (fans and filters) is physically incapable of cooling the internal components below the ambient air temperature. If the electronics are rated for 50°C, and the air outside is 45°C, a fan system has a theoretical maximum cooling potential of 5°C delta, which is insufficient once solar load and internal heat dissipation are factored in. The result is thermal runaway, throttled CPUs, and eventual component failure.

Scenario B: The Coastal Sensor Array

In a marine or coastal application, the enemy is not just heat, but salt fog. A standard filtration system, even with high-MERV ratings, eventually succumbs to salt encrustation, which restricts airflow and corrodes internal circuitry. To protect the electronics, the enclosure must be sealed to NEMA 4X or IP65 standards. Once the enclosure is sealed, airflow is eliminated. The heat generated by the power supplies and processors is trapped inside the chassis, turning the protective enclosure into an oven. Here, the requirement for sealed outdoor enclosure cooling is driven by the need for environmental isolation as much as thermal management.

Technical Friction Points & Failure Modes

When designing outdoor enclosures, engineers encounter specific friction points where passive methods consistently fail. Understanding these failure modes is critical for justifying the shift to active cooling.

- The Filter Paradox: In passive systems, higher ingress protection requires denser filters. Denser filters create higher static pressure, drastically reducing airflow (CFM). To maintain airflow, you need more powerful fans, which consume more power and generate more noise, yet still fail to cool below ambient temperature. Eventually, the filter clogs, airflow drops to near zero, and the system overheats.

- Moisture and Condensation: Sealed enclosures without active humidity control are susceptible to the “dew point” phenomenon. As temperatures drop at night, internal air contracts and cools, potentially causing suspended moisture to condense on circuit boards. Passive heat exchangers cannot actively dehumidify the air.

- Thermal Runaway: In a sealed box relying solely on conduction (passive heat sinks), the internal temperature will always rise until the temperature gradient is sufficient to drive heat through the enclosure walls. For high-density electronics (100W+), the internal temperature required to drive this heat transfer often exceeds the safe operating limits of the components (e.g., >60°C).

- Battery Degradation: For systems relying on battery backup (UPS), heat is a silent killer. Every 10°C rise above 25°C cuts the life of a lead-acid battery in half. Passive cooling is rarely sufficient to keep batteries within their optimal range in outdoor summer conditions.

Engineering Fundamentals: The Active Cooling Advantage

The solution to these friction points lies in decoupling the internal environment from the external environment. This is the fundamental definition of sealed outdoor enclosure cooling using active vapor-compression systems.

Closed-Loop Thermodynamics

Active cooling systems, such as the Micro DC Aircon, operate on a closed-loop principle. The air inside the enclosure is circulated through an evaporator coil, cooled, and returned to the electronics. It never mixes with the outside air. This isolation preserves the NEMA/IP rating of the cabinet, ensuring that dust, salt, and moisture remain outside.

The Physics of Vapor Compression

Unlike Peltier (thermoelectric) coolers, which are inefficient for loads above 100W, vapor-compression systems utilize a refrigerant cycle to pump heat against the thermal gradient. A BLDC inverter rotary compressor compresses a refrigerant (such as R134a), raising its pressure and temperature. This hot gas is condensed into a liquid in the condenser (rejecting heat to the outside), then expanded into a gas in the evaporator (absorbing heat from the inside). This phase-change process is significantly more energy-efficient per watt of cooling than thermoelectric methods, making it the standard for industrial sealed outdoor enclosure cooling.

Active Dehumidification

A secondary but vital benefit of the vapor-compression cycle is dehumidification. As air passes over the cold evaporator coil, moisture condenses and is collected or evaporated externally. This actively lowers the dew point inside the enclosure, preventing the condensation risks associated with diurnal temperature swings.

Performance Data & Verified Specs

To move from theory to practice, we must look at the specifications of verified solutions. Arctic-tek’s Micro DC Aircon series provides a baseline for what engineers should expect from a ruggedized, active cooling unit. These units are designed to run directly on DC power (12V, 24V, or 48V), eliminating the efficiency losses associated with inverters required for AC air conditioners.

| Model (Example) | Voltage | Nominal Cooling Capacity | Refrigerant | Compressor Type |

|---|---|---|---|---|

| DV1910E-AC (Pro) | 12V DC | 450W | R134a | BLDC Inverter Rotary |

| DV1920E-AC (Pro) | 24V DC | 450W | R134a | BLDC Inverter Rotary |

| DV1930E-AC (Pro) | 48V DC | 450W | R134a | BLDC Inverter Rotary |

| DV3220E-AC (Pro) | 24V DC | 550W | R134a | BLDC Inverter Rotary |

Key Technical Parameters:

- Cooling Capacity (100W–900W): The series covers the critical range for micro-enclosures and kiosks. For example, the DV1920E-AC provides 450W of cooling, which is typically sufficient to offset the heat load of an industrial PC, a 4G/5G modem, and a small UPS, plus the solar load on a medium-sized cabinet.

- DC Voltage Integration: By operating natively on 12V, 24V, or 48V, these units integrate directly with the battery bank or DC bus of the kiosk. This is crucial for off-grid or solar-powered applications where energy efficiency is paramount.

- Inverter Control: The BLDC inverter compressor allows for variable speed operation. Instead of hard cycling (on/off), which causes voltage spikes and temperature fluctuations, the compressor ramps up or down to match the heat load. This precise control stabilizes the internal temperature and reduces mechanical stress on the system.

Field Implementation Checklist: Best Practices

Implementing a sealed outdoor enclosure cooling solution requires attention to detail during the design and installation phases. The following checklist outlines best practices derived from field deployments.

Mechanical Integration

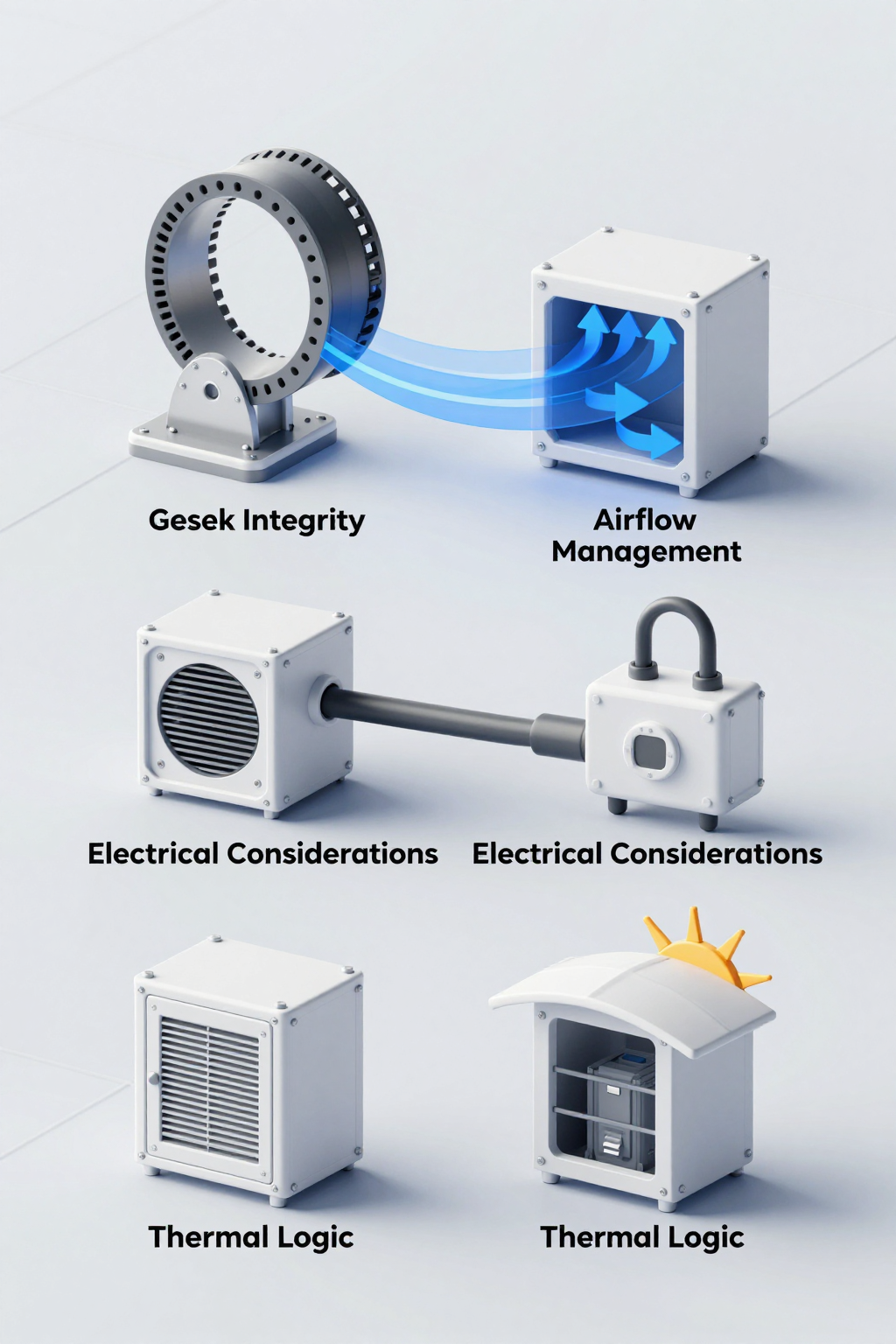

- Gasket Integrity: Ensure the mounting interface between the air conditioner and the enclosure is perfectly flat and sealed with the provided closed-cell foam gasket. Any gap here compromises the IP rating.

- Airflow Management: Do not block the intake or exhaust ports of the air conditioner. Inside the cabinet, ensure that the cold air discharge is directed towards the hottest components (e.g., the CPU or power supply) and that the return air path is unobstructed. Short-cycling the air (where cold air is immediately sucked back into the intake) will severely reduce efficiency.

- Mounting Orientation: While some compressors are robust, verify the allowable tilt angles. Generally, vapor-compression units should be mounted upright to ensure proper oil return to the compressor.

Electrical Considerations

- Cable Sizing: DC motors draw significant current, especially at lower voltages (12V). Use appropriately sized gauge wire to minimize voltage drop between the power source and the cooling unit. A voltage drop at the unit can trigger low-voltage cutoffs.

- Circuit Protection: Always install a dedicated fuse or breaker for the cooling unit, sized according to the maximum current draw specified in the manual.

Thermal Logic

- Solar Shielding: Even with active cooling, passive measures help. Installing a sunshield or “rain hood” over the enclosure can reduce the solar load by 50%, allowing the Micro DC Aircon to run at a lower speed and consume less power.

- Insulation: Insulating the enclosure walls helps maintain the temperature differential created by the active cooling system, preventing heat ingress from the hot exterior chassis.

Expert Field FAQ

Q: Why can’t I just use a larger fan for sealed outdoor enclosure cooling?

A: Fans are open-loop systems. They cannot cool below the ambient air temperature. If the outside air is 45°C, your electronics will be at least 45°C (plus internal heat rise). Furthermore, fans compromise the seal, allowing dust and moisture ingress.

Q: How does the Micro DC Aircon handle condensation inside the cabinet?

A: The cold evaporator coil naturally collects moisture from the internal air as it circulates. This moisture condenses into water droplets, which are drained out of the enclosure, effectively dehumidifying the internal environment.

Q: What is the advantage of a 48V system over a 12V system?

A: Higher voltage results in lower current for the same power. A 48V system (like the DV1930E-AC) requires thinner cables and suffers less voltage drop over distance compared to a 12V system, making it more efficient for larger installations.

Q: Can these units operate in a moving vehicle?

A: Yes. The Micro DC Aircon series utilizes rotary compressors which are inherently more resistant to vibration and tilt than reciprocating compressors, making them suitable for mobile applications.

Q: Do I need to refill the refrigerant?

A: No. These are hermetically sealed systems, similar to a residential refrigerator. Unless there is physical damage causing a leak, the refrigerant (R134a) does not need to be replenished.

Q: How does the noise level compare to a fan tray?

A: While a compressor does generate sound, the variable speed nature of the BLDC motor means it often runs at partial load, which is relatively quiet. Additionally, because the enclosure is sealed, internal noise is dampened.

Conclusion & System Logic

The transition from passive ventilation to active sealed outdoor enclosure cooling is a strategic decision that prioritizes reliability over short-term savings. While fans and filters offer a lower upfront cost, they introduce significant risks in terms of contaminant ingress and thermal limitations. For mission-critical outdoor electronics—whether in telecommunications, automation, or security—the cost of a single downtime event often exceeds the cost of a proper thermal management solution.

By leveraging the Micro DC Aircon series, engineers can ensure a clean, cool, and dry environment for their sensitive components, regardless of the external chaos. The combination of closed-loop isolation, high-efficiency vapor compression, and intelligent DC control provides a robust defense against the elements. When the environment is hostile, the cooling must be active.

For specific sizing assistance or to discuss the integration of the DV series into your next OEM project, consult the Arctic-tek engineering team for a detailed thermal analysis.

0 条评论