Angle: The decision is whether to specify a purpose-built micro DC air conditioner or attempt to integrate a cheaper, repurposed consumer/RV AC unit for a sealed electronics enclosure. The two most likely failure modes are catastrophic electronics failure from unmanaged condensation and premature AC unit burnout from high-duty cycles and vibration. The dominant constraint is maintaining the enclosure’s seal and IP rating against environmental ingress.

The Critical Choice: Micro DC Aircon vs. RV Air Conditioner for Industrial Enclosures

For engineers designing systems housed in sealed enclosures—from telecom cabinets and trackside control boxes to autonomous vehicle sensor pods—thermal management is not a luxury; it’s a core component of system reliability. When the internal heat load exceeds what passive cooling can handle, active cooling becomes necessary. This is where a critical, and often costly, decision arises. The temptation to repurpose a consumer-grade window or RV air conditioner is strong, driven by upfront cost savings. However, this path is riddled with hidden risks that can lead to catastrophic system failure, field service nightmares, and ultimately, higher total cost of ownership. The debate over a **micro dc aircon vs rv air conditioner; repurposed ac enclosure risks** is not about cooling capacity alone; it’s about design intent, reliability, and integration integrity.

By the end of this analysis, you will be able to confidently justify the selection of a purpose-built cooling solution by articulating the specific engineering trade-offs and failure modes associated with repurposed units. In this article, we prioritize long-term reliability and predictable performance over minimal upfront cost, because in industrial applications, unplanned downtime is the most expensive outcome.

Deployment Context: Where Repurposed Solutions Fail

The theoretical appeal of a low-cost consumer AC unit quickly evaporates in the face of real-world industrial environments. These two micro-scenarios illustrate common failure pathways.

Scenario A: Roadside Control Cabinet

A system integrator deploys a series of traffic control cabinets containing sensitive PLCs and networking gear. To save on the bill of materials, they modify the cabinet doors to fit small, 8,000 BTU window air conditioners powered by an inverter. Within six months, half the units are failing. The primary issue is vibration from passing traffic, which consumer-grade compressors and refrigerant lines were never designed to withstand, leading to coolant leaks. Furthermore, their crude condensate drainage system—a simple drip pan and tube—clogs with dust and debris, causing water to overflow directly onto the power distribution block, shorting out the entire cabinet.

Scenario B: Outdoor Digital Signage

An OEM for outdoor digital signage kiosks uses a compact RV air conditioner to cool the high-brightness display drivers and media player. The enclosure is meant to be NEMA 4 rated, but cutting a large hole for the RV unit and attempting to seal it with gaskets proves unreliable. During a severe rainstorm, water ingress through the poorly sealed AC unit compromises the system. Separately, the AC unit’s thermostat, designed for human comfort in a large volume, causes rapid on/off cycling. This frequent, high-inrush current draw stresses the power supply and eventually leads to the compressor motor burning out, leaving the expensive display electronics to cook in the summer sun.

Failure Modes & Constraints: The True Cost of Repurposing

When evaluating a **micro dc aircon vs rv air conditioner**, the long-term failure modes of the repurposed option must be ranked and quantified. These are not edge cases; they are predictable outcomes of misapplying a product outside its intended operating environment.

- Seal & IP/NEMA Rating Compromise → Water/Dust Ingress → Catastrophic failure of all internal electronics, voiding warranties.

- Unmanaged Condensate → Internal Water Pooling/Dripping → Corrosion, short circuits, and immediate equipment failure.

- AC Power Inversion Inefficiency → DC-AC Conversion Loss → Wasted energy, increased thermal load on the power system, and an additional point of failure.

- Vibration & Shock Intolerance → Refrigerant Line Fracture/Component Failure → Loss of cooling, costly field replacement, and potential environmental non-compliance.

- Crude Thermostatic Control → High-Current Inrush & Short Cycling → Premature compressor failure and severe stress on the DC power supply.

- Oversized Cooling Capacity → Rapid Cycling & Poor Dehumidification → Inefficient operation and condensation forming on electronics as temperatures swing past the dew point.

- Lack of Intelligent Control → No Variable-Speed Operation → Inability to match cooling to the actual load, leading to wasted power and unnecessary mechanical wear.

- Bulky Form Factor & Awkward Mounting → Compromised Enclosure Design → Wasted internal space, difficult service access, and non-standard mounting that complicates manufacturing.

- Designed for Open-Loop Airflow → Inefficient Cooling of a Sealed Box → The unit fights to cool the entire ambient environment instead of efficiently recirculating and cooling the internal air.

Engineering Fundamentals: Closed-Loop vs. Open-Loop Cooling

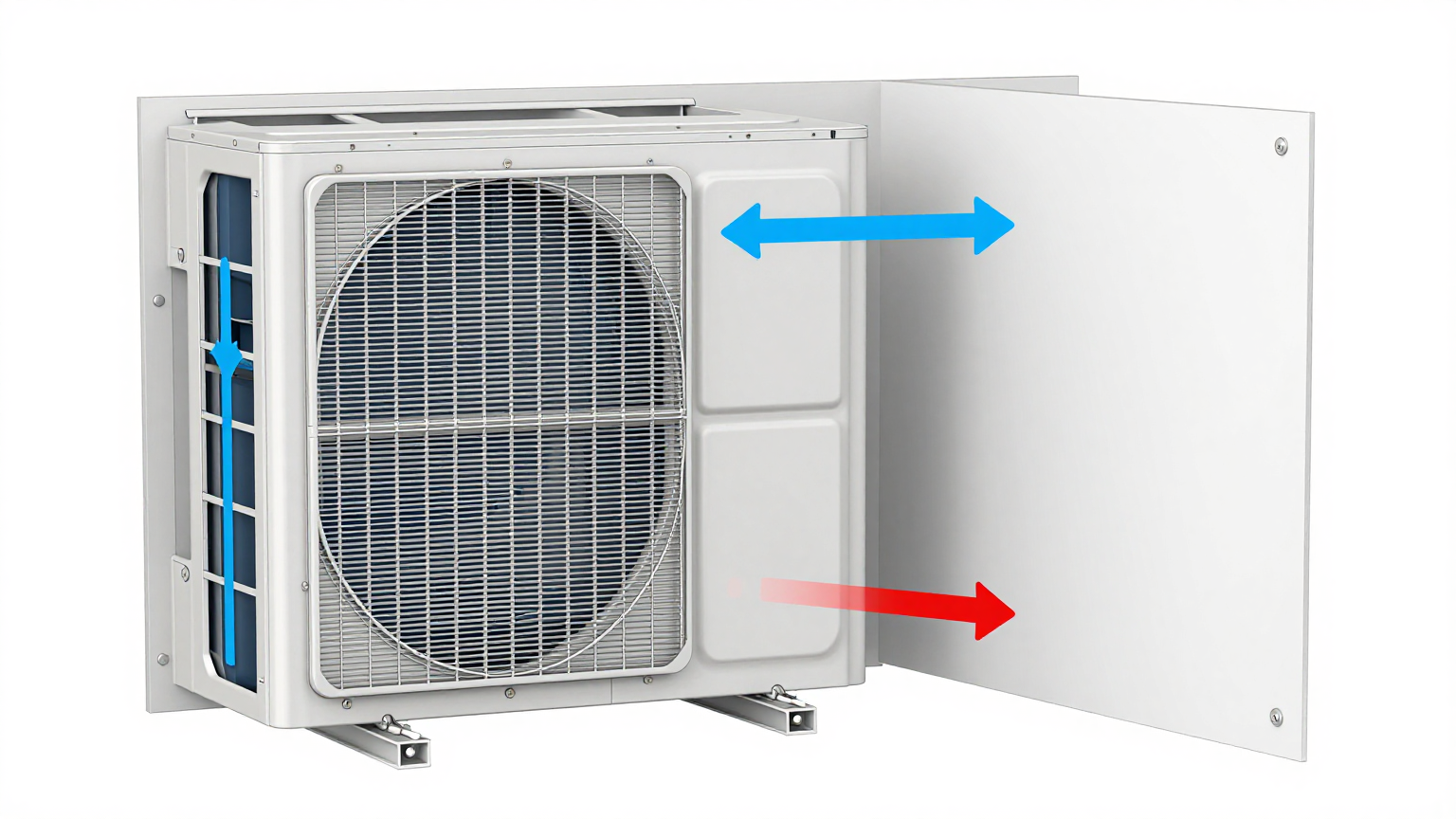

The most critical engineering distinction in the **micro dc aircon vs rv air conditioner** debate is the airflow path. A repurposed RV or window unit is an open-loop system. It is designed to draw hot, humid air from the conditioned space, pass it over an evaporator coil, and return cool, dehumidified air. The condenser coil, which ejects the heat, is simultaneously rejecting heat into the outside ambient air. In an enclosure, this is disastrous. You cannot simply cut a hole and mount it without creating two separate, sealed air paths: one for the internal enclosure air (the “cold side”) and one for the external ambient air (the “hot side”).

A purpose-built **micro dc aircon** is an integrated closed-loop system. It mounts *through* the enclosure wall, creating a natural seal. The internal evaporator fan and coil interact only with the air inside the cabinet, creating a sealed recirculation loop. The external condenser fan and coil interact only with the ambient outside air. This separation is fundamental to maintaining an IP/NEMA rating and preventing the ingress of dust, moisture, and corrosive agents. It also ensures that the unit is only cooling the internal heat load, not fighting a constant battle against incoming hot ambient air.

Misconception & Correction: A common misconception is that any air conditioner dehumidifies effectively. While technically true, a grossly oversized unit (like most RV ACs for a small enclosure) will cool the air so quickly that it shuts off before it has time to condense and remove a significant amount of water vapor from the air. This leads to a cold, clammy internal environment where electronics are still at risk from condensation. A properly sized **micro dc aircon** with variable-speed control can run at a lower, continuous speed, which is far more effective at managing both temperature and humidity, keeping the internal air safely above its dew point.

Specification Gateway: Comparing Design Intent

When selecting a cooling solution, the spec sheet tells the story of the product’s intended application. A direct comparison reveals why repurposed units present significant **repurposed ac enclosure risks**. The table below shows typical parameters for our Micro DC Aircon series, designed specifically for these applications.

| Parameter | Micro DC Aircon Series | Typical Repurposed RV/Consumer AC |

|---|---|---|

| Input Voltage | Native 12V / 24V / 48V DC | 110V / 220V AC (Requires DC-AC Inverter) |

| Cooling Capacity | 100W – 900W (Right-sized for electronics) | 1,500W+ (5,000 BTU+) (Grossly oversized) |

| Compressor Control | Variable-speed BLDC Inverter | Fixed-speed, On/Off Thermostat |

| Form Factor | Compact, integrated for enclosure mounting | Bulky, designed for window/roof mounting |

| Airflow Design | Closed-loop (separate internal/external paths) | Open-loop (assumes shared air volume) |

| Condensate Management | Integrated, often with atomization or drain port | Basic drip pan, relies on gravity |

| Vibration Resistance | Engineered for mobile/industrial environments | Designed for stationary residential use |

To read these specs for our decision, focus on the mismatches. The native DC input of a **micro dc aircon** eliminates the need for a bulky, inefficient, and failure-prone inverter. The right-sized cooling capacity and variable-speed control prevent the damaging short-cycling common with oversized consumer units. The entire architecture is built around maintaining a sealed, reliable system. For instance, an example unit like the DV1920E-AC (Pro) offers 450W of cooling from a native 24V DC source in a compact, vibration-resistant package—a set of specifications you simply cannot find in the consumer market.

Engineering Selection Matrix: Logic Gates for Thermal Management

An engineer must move past the initial cost question and apply a series of logic gates to determine the correct thermal solution. This matrix forces an evaluation of the true system requirements and exposes the hidden liabilities of repurposed hardware.

Logic Gate 1: Power Source Integrity

- Constraint Gate: Is the primary power source low-voltage DC (e.g., 12V, 24V, 48V battery or bus)?

- Decision Trigger: If the source is native DC, introducing an AC-powered appliance requires adding a DC-to-AC power inverter.

- Engineering Resolution: The addition of an inverter introduces a significant efficiency loss (typically 10-15%), a new thermal load inside the cabinet, and a critical single point of failure. Specifying a native DC-powered solution like a **micro dc aircon** eliminates these three risks entirely, simplifying the power architecture and increasing overall system reliability.

- Integration Trade-off: Choosing a native DC unit requires properly sizing the DC power supply and wiring for the compressor’s peak load, but it removes the complexity and failure modes of an inverter.

Logic Gate 2: Environmental Seal Requirement

- Constraint Gate: Does the enclosure require a specific IP (Ingress Protection) or NEMA rating to protect against dust, water, or corrosive elements?

- Decision Trigger: If the rating is IP54 or higher, any penetration of the enclosure wall must be properly sealed.

- Engineering Resolution: A repurposed RV or window unit requires extensive custom fabrication and sealing, which is notoriously difficult to execute reliably in production. A purpose-built enclosure air conditioner is designed with an integrated mounting flange and gasket system to maintain the seal as part of its core design. The choice becomes one between a standard, repeatable installation process and a high-risk, custom fabrication project for every unit. This is a primary factor when considering the **repurposed ac enclosure risks**.

- Integration Trade-off: The purpose-built unit may have a higher upfront cost, but it drastically reduces labor, fabrication complexity, and the immense financial risk of field failures due to water/dust ingress.

Logic Gate 3: Ambient Temperature vs. Internal Setpoint

- Constraint Gate: Can the internal electronics tolerate temperature swings, or must they be held within a narrow band for performance and longevity (e.g., below 40°C)?

- Decision Trigger: If the maximum ambient temperature can exceed the maximum allowable internal temperature, active, refrigerated cooling is non-negotiable. A simple fan or heat exchanger will not suffice.

- Engineering Resolution: The choice is now between two types of refrigerated systems. A repurposed unit with on/off control will create significant temperature oscillations around the setpoint. A **micro dc aircon** with a variable-speed compressor can modulate its output to precisely match the heat load, holding the internal temperature stable. This stability is critical for sensitive lasers, imaging sensors, and processors that can suffer from performance degradation or damage due to thermal cycling.

- Integration Trade-off: Implementing a variable-speed drive adds some complexity to the control board but provides superior performance, higher efficiency, and lower mechanical stress compared to a fixed-speed system.

Implementation Checklist: Installation & Verification

Proper installation is as critical as proper selection. A checklist ensures that the reliability designed into the unit is realized in the field.

-

Mechanical Installation

- Cutout & Mounting: Use the manufacturer’s template for the enclosure cutout. Ensure all surfaces are clean and burr-free for a proper gasket seal.

- Gasket Integrity: Verify the gasket is fully compressed and creates a continuous seal around the unit. Torque mounting bolts to the specified values.

- Airflow Path: Confirm that no internal cables, brackets, or components are obstructing the evaporator’s inlet or outlet. Likewise, ensure the external condenser has unobstructed airflow.

-

Electrical Connection

- Power Budget: Use wire gauges appropriate for the unit’s maximum current draw at the specified DC voltage, accounting for voltage drop over the cable length.

- Circuit Protection: Install a correctly rated fuse or circuit breaker on the positive line as close to the power source as possible.

- Polarity & Grounding: Double-check DC polarity before powering on. Ensure a proper chassis ground is connected as per the installation manual.

-

Thermal Verification

- Sensor Placement: Place an independent temperature sensor near the inlet of the evaporator (representing the hottest internal air) and another near sensitive components to validate performance.

- Acceptance Test: Power on the system and allow it to run for a 30-minute stabilization period. Verify that the internal temperature is maintained at the desired setpoint while the compressor is running smoothly.

- Condensate Check: In humid conditions, check that the condensate management system is functioning correctly and that no water is accumulating inside the enclosure.

-

Maintenance & Service

- Filter & Coil Cleaning: Schedule periodic checks (e.g., every 6 months) to clean the condenser coils of dust and debris to maintain thermal efficiency.

- Access Planning: Ensure the final assembly allows service access to the air conditioner without requiring a complete system teardown.

Frequently Asked Questions (FAQ)

Addressing common objections and questions from engineers evaluating a **micro dc aircon vs rv air conditioner**.

1. Can’t I just build a better seal around an RV air conditioner?

While possible with enough custom fabrication, it’s unreliable and not scalable for production. You are essentially designing and validating a new sealing system, which adds significant engineering overhead and risk. A purpose-built unit has this engineered and tested from the factory.

2. What about condensation? How is it managed in a sealed box?

Micro DC Aircon units manage condensate in a closed-loop system. Some models use a high-surface-area evaporator and route the condensate to the hot condenser coil, where it is atomized and evaporated into the external airflow. Others provide a dedicated drain port for controlled routing. A repurposed unit’s simple drip pan is a major liability for **repurposed ac enclosure risks**.

3. How do these units handle direct sun, dust, or salt fog?

Industrial units are designed for harsh environments. Features often include corrosion-resistant coatings, robust fan motors, and designs that shield sensitive parts from direct weather. A consumer unit, even for an RV, is not built to the same standards of material durability and environmental resistance.

4. What is the most important measurement I need to take before selecting a unit?

You need to calculate your total internal heat load (in watts) from all electronics, and factor in the solar load if the enclosure is outdoors. This, combined with your maximum ambient temperature and desired internal temperature, determines the required cooling capacity. Over-sizing is as problematic as under-sizing.

5. How can I validate the cooling performance after installation?

The best method is thermal logging. Place thermocouples on your most critical components and in the ambient air path. Log the temperatures during a full operational cycle under maximum heat load on a hot day. The data should show that component temperatures remain well within their safe operating limits.

6. Is a DC-powered air conditioner really more efficient than an AC one with an inverter?

Yes. Every power conversion step introduces loss, which manifests as heat. By running directly from a DC source, a **micro dc aircon** avoids the 10-15% energy loss of a DC-AC inverter. This means more of your power goes to cooling and less is wasted as additional heat within your system.

Conclusion: Design Intent Dictates Reliability

The decision between a purpose-built **micro dc aircon vs rv air conditioner** is a classic engineering trade-off: perceived upfront savings versus long-term reliability and total cost of ownership. While a repurposed consumer unit might function on a test bench, it introduces a cascade of risks in an industrial deployment—from compromised seals and power inefficiencies to premature failure from vibration and improper control. The **repurposed ac enclosure risks** are not hypothetical; they are the predictable result of using a product outside of its engineered design intent.

A Micro DC Aircon is the best-fit solution when the application demands a native DC power source, a guaranteed environmental seal (IP/NEMA rating), precise temperature control, and resilience to shock and vibration. For any critical system where downtime is unacceptable, the integrated, purpose-built approach is the only one that aligns with sound engineering principles. For more information on our compact cooling solutions, see our full line of Micro DC Aircon products.

If you are facing unique thermal challenges related to enclosure geometry, power constraints, or harsh environments, our engineering team can assist with sizing and customization. Contact us to discuss your specific project requirements.

0 条评论